Loading ...

Loading ...

Loading ...

and where appropriate, the general position of infills in the assembly. In

addition, if certain infills have a fixed size, it is helpful to indicate these as

well. Different infill types are separated with a “+” symbol. These are loose

guidelines at best; the very flexibility of door/window assembly styles and

virtually unlimited combination of infills and grids makes it impossible to

develop a fixed naming convention that will apply to all conditions:

<Infill Type> <Optional Infill Size> <Optional Infill Position> <Optional Cell Adjustment

Parameter> + <Next Infill Type>....<Optional Door/Window Assembly Shape>

NOTE Door/Window Assemblies with no shape specified are assumed to be

rectangular. In the case of a very complex door/window assembly, you may choose

to omit some of the less prominent infill types and parameters, choosing instead

to include them in a more complete style description.

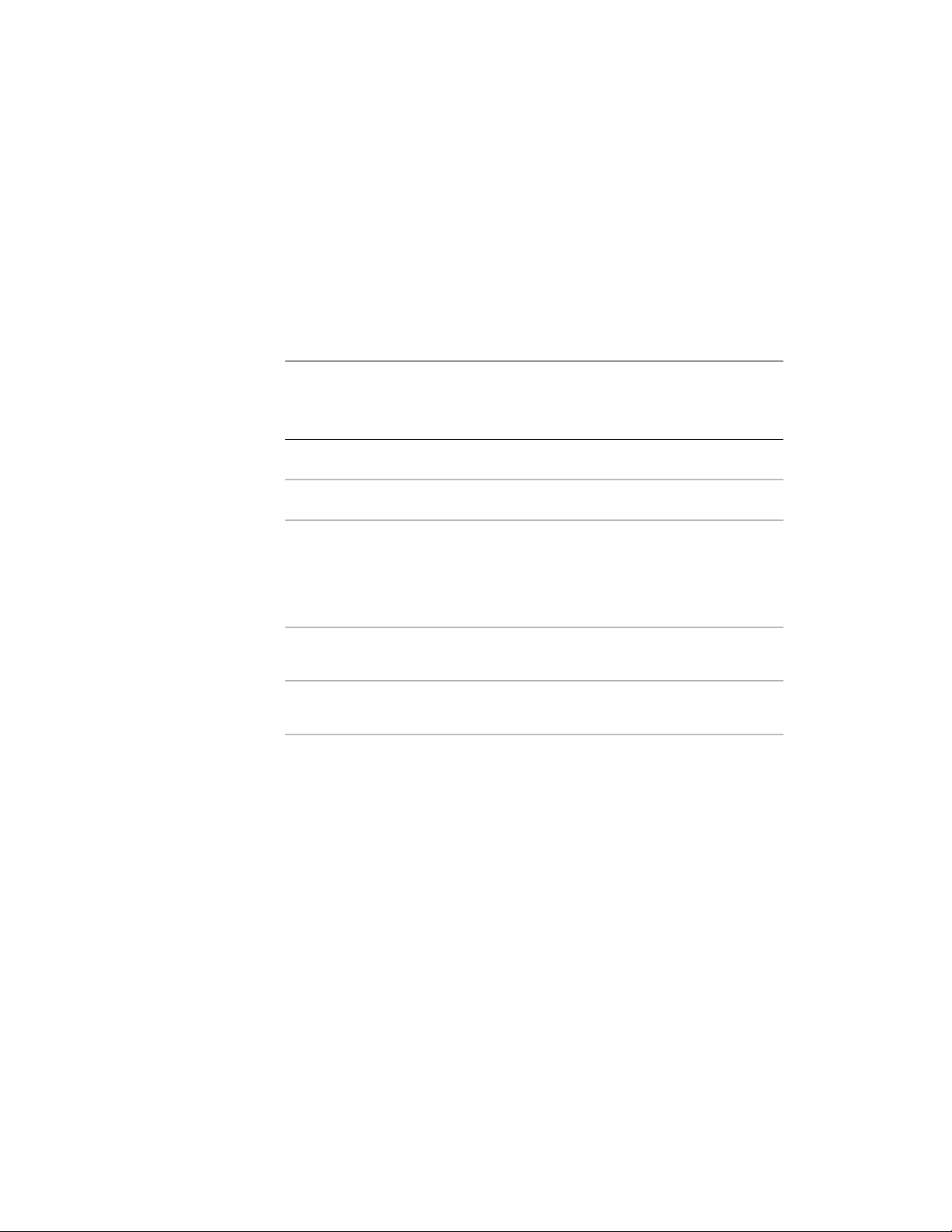

Example Door/Window Assembly Style Names:

Example NameDoor/Window Assembly Style Descrip-

tion

Windows4-0 Ctr Grow + Transom 2-0 Ctr

Arched

An arched assembly with 4’ windows and

a two foot tall arched transoms, centered,

with both side cells configured to grow as

the assembly width is changed until the 4’

size can be accommodated

Hinged Double 6-0x6-8 + Sidelights +

Transom

Hinged double door with variable width

sidelights on each side and a transom.

Hinged Single 3-9x6-8 Right + Sidelight

+ Transom

A hinged single door on the right side with

a single sidelight and a transom.

Best Practices for Door/Window Assembly Styles:

■ All assembly components should have materials assigned to them.

■ Door/Window Assembly styles should be classified for more control with

scheduling and display control. This is especially important with assemblies

that are explicitly intended to be included in a window or door schedule

as a mulled unit.

Architectural Objects | 945

Loading ...

Loading ...

Loading ...