Loading ...

Loading ...

Loading ...

The essentials

●

Hol

d the wheel br

ace at the end and r

otate

the bolt approximately one turn anticlockwise

›››

.

Impor

t

ant inf

ormation about wheel bolts

The wheel rims and bolts have been de-

signed to be fitted to factory options. If differ-

ent rims are fitted, the correct wheel bolts

with the right length and correctly shaped

bolt heads must be used. This ensures that

wheels are fitted securely and that the brake

system functions correctly.

In some circumstances, wheel bolts from the

same model vehicle should not be used.

Wheel bolt tightening torque

The prescribed tightening torque for wheel

bolts for steel and alloy wheels is 140 Nm.

Have the tightening torque of the wheel bolts

checked as soon as possible with a reliable

torque wrench.

If wheel bolts are rusty and it is difficult to

tighten them, the threads should be replaced

and cleaned before checking the tighten-

ing torque.

Never grease or lubricate wheel bolts or the

wheel hub threads. Although they have been

tightened to the prescribed torque, they

could come loose while driving.

WARNING

If the wheel bolts are not fitted correctly

they could be rel

eased while driving lead-

ing to loss of vehicle control and serious

damage.

●

Only use wheel bolts which correspond

to the wheel rims in question.

●

Never use different wheel bolts.

●

The bolts and threads should be clean,

free of oil and grease and easy to thread.

●

To loosen and tighten the wheel bolts, al-

ways use the wheel brace supplied with the

vehicle.

●

Loosen the wheel bolts only about one

turn before raising the vehicle with the jack.

●

Never grease or lubricate wheel bolts or

the wheel hub threads. Although they have

been tightened to the prescribed torque,

they could come loose while driving.

●

Never loosen the bolted joints of wheel

rims with bolted ring trims.

●

If the wheel bolts are not tightened to the

correct torque, they may come loose while

driving, and the bolts and rims may come

out. If the tightening torque is too high, the

wheel bolts and threads can be damaged.

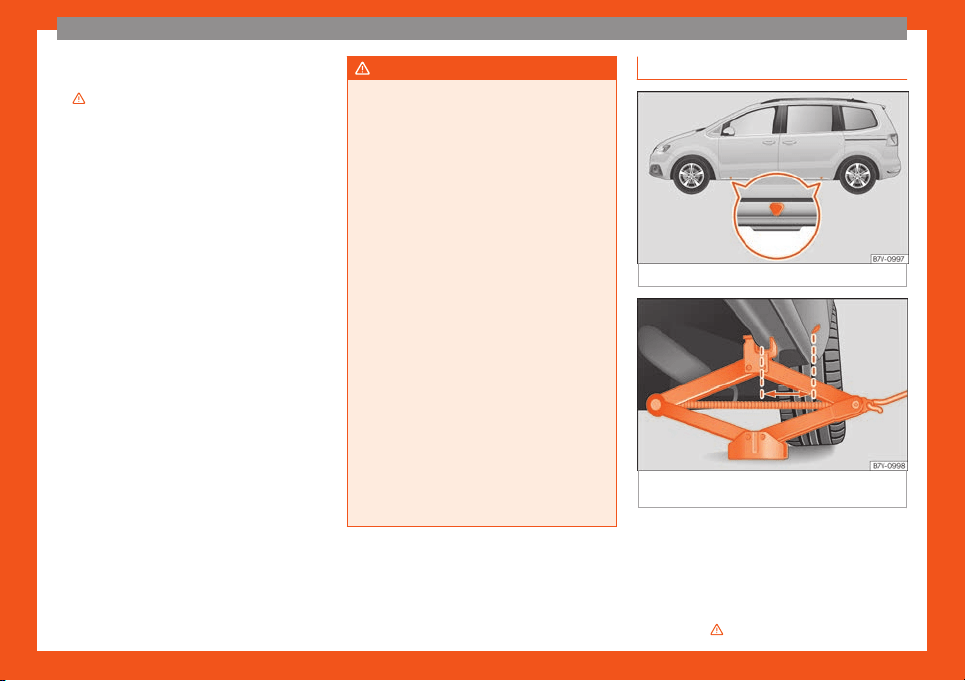

Raising the vehicle with the jack

Fig. 71

Jack position points.

Fig. 72

Jack mounted on the left rear part of

the v

ehicl

e

The jack may be applied only at the jacking

points sho

wn (marks on chassis)

›

›

›

Fig. 71.

The mark indicates the jacking points below

the vehicle. The jacking points are on the ribs

behind the front edges

›››

Fig. 72. Always the

relevant jacking point for the wheel to be

changed

›››

.

50

Loading ...

Loading ...

Loading ...