Loading ...

Loading ...

Loading ...

VDL (E3.1) 10/2020 Page 85/196

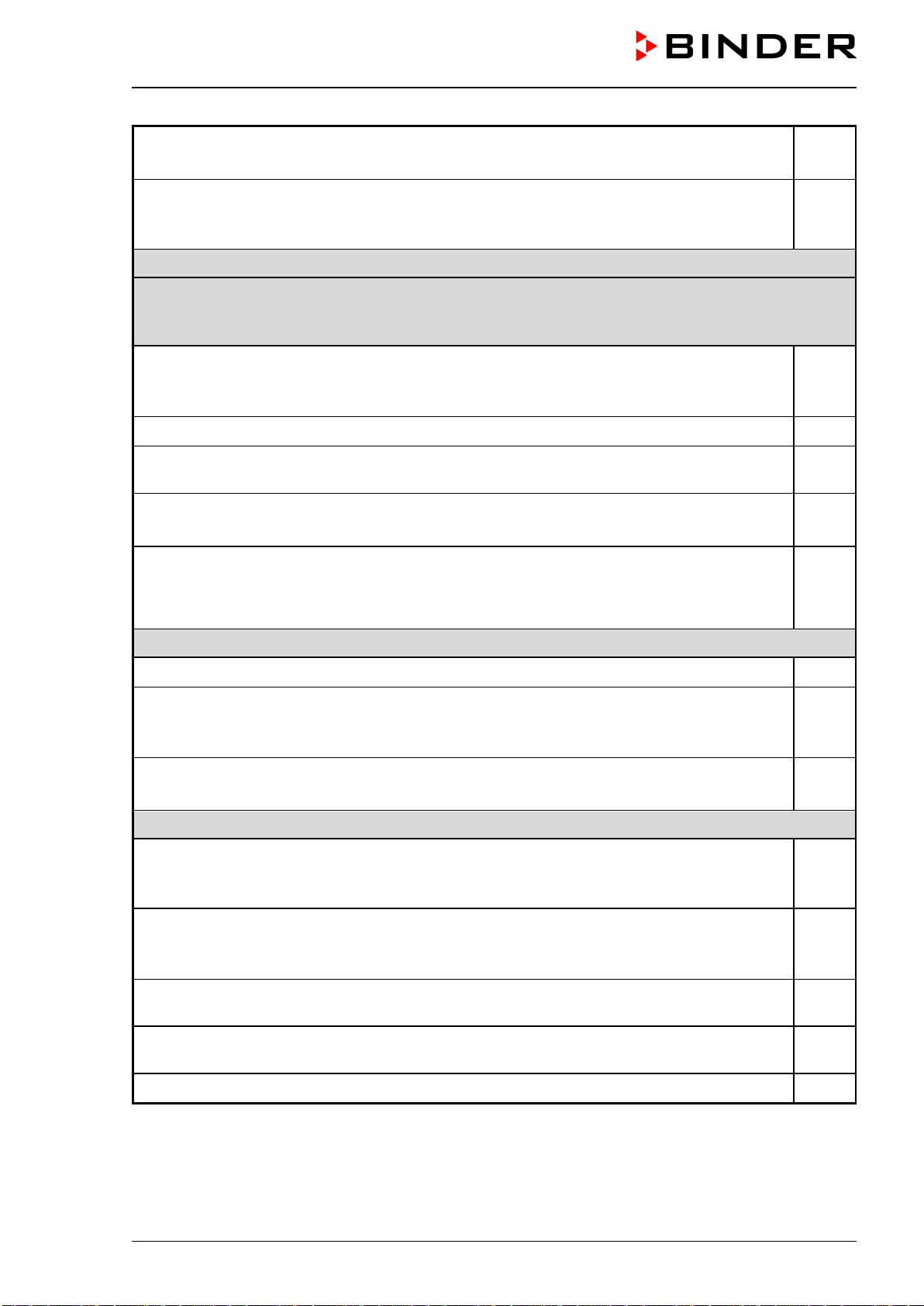

• Make sure that the user's equipment is ESD protected.

• Place the material to be dried in the chamber.

□

• Set the pressure set-point on the controller.

Heating will start only when a vacuum corresponding to the pressure threshold of 100 mbar)

is reached.

□

The drying process is running.

After completing the drying process or when cancelling the drying process

When the pressure drops to the pressure set-point, the drying process is finished. If the drying monitor-

ing (chap. 11.6) is activated, a corresponding message is displayed.

• Make sure that the technical ventilation is activated

• Make sure that equipotential bonding has been established according to the grounding con-

cept

□

• For ventilation, set the pressure set-point to atmospheric pressure

□

• Switch the vacuum drying oven on the controller to standby mode (not completely de-ener-

gized)

□

• Make sure that the user's equipment is ESD protected.

• Remove the drying material

□

• Continue sweeping the electrical installation area, preheating chamber and controller hous-

ing with an overpressure of at least 25 Pa (recommendation: >40 Pa) for at least 10 minutes

(recommended). Check the excess pressure on the manometer. Only then shut off the com-

pressed air supply.

□

For emptying the pump

• Make sure that the pump is turned off.

□

• Make sure that the technical ventilation is activated

• Make sure that equipotential bonding has been established according to the grounding con-

cept

□

• Make sure that the user's equipment is ESD protected.

• Remove the full condensate catchpot of the pump

□

Before starting a new drying process

In case of a new solvent with a different auto-ignition temperature:

• Determine the auto-ignition temperature of the solvent from its safety specifications. In the

case of solvent mixtures, use the lowest auto-ignition temperature

□

• Make sure that the technical ventilation is activated

• Make sure that equipotential bonding has been established according to the grounding con-

cept

□

• Sweep the area for electrical equipment, preheating chamber and the controller housing

with compressed air at maximum overpressure for a defined time (chap. 9.3.2).

□

• Turn on the chamber and check the settings (drying temperature, pressure set-point and

safety controller setting)

□

• Now you can load the chamber and start the new drying process. Follow all safety measures

□

Loading ...

Loading ...

Loading ...