Loading ...

Loading ...

Loading ...

VDL (E3.1) 10/2020 Page 35/196

2.7 Testing and maintenance

The operator must ensure that the chamber is always in a technically functional state.

Observe the maintenance intervals specified by the manufacturer. If there is above-average strain, the

intervals must be shortened accordingly.

The operator must regularly verify that the safety-related devices are functioning correctly.

Document tests with results and measures that were potentially initiated, as well as maintenance and re-

pairs, in a system book.

For testing before commissioning, see Chap. 7

For recurring tests and maintenance, see Chap. 7.5, 7.6, 25.

2.8 Operation log

For safety reasons, keeping an operation log which documents each individual drying process is recom-

mended.

The following contents should be entered and recorded:

• Type of solvent

• Auto-ignition temperature of the solvent; in the case of solvent mixtures: solvent with the lowest Auto-

ignition temperature

• Entered temperature set-point (drying temperature)

• Drying temperature set-point

• Set safety controller mode temperature (Limit/Offset)

• Set safety controller value

• Date

• Signature

Use the following specimen or compile it in a suitable form.

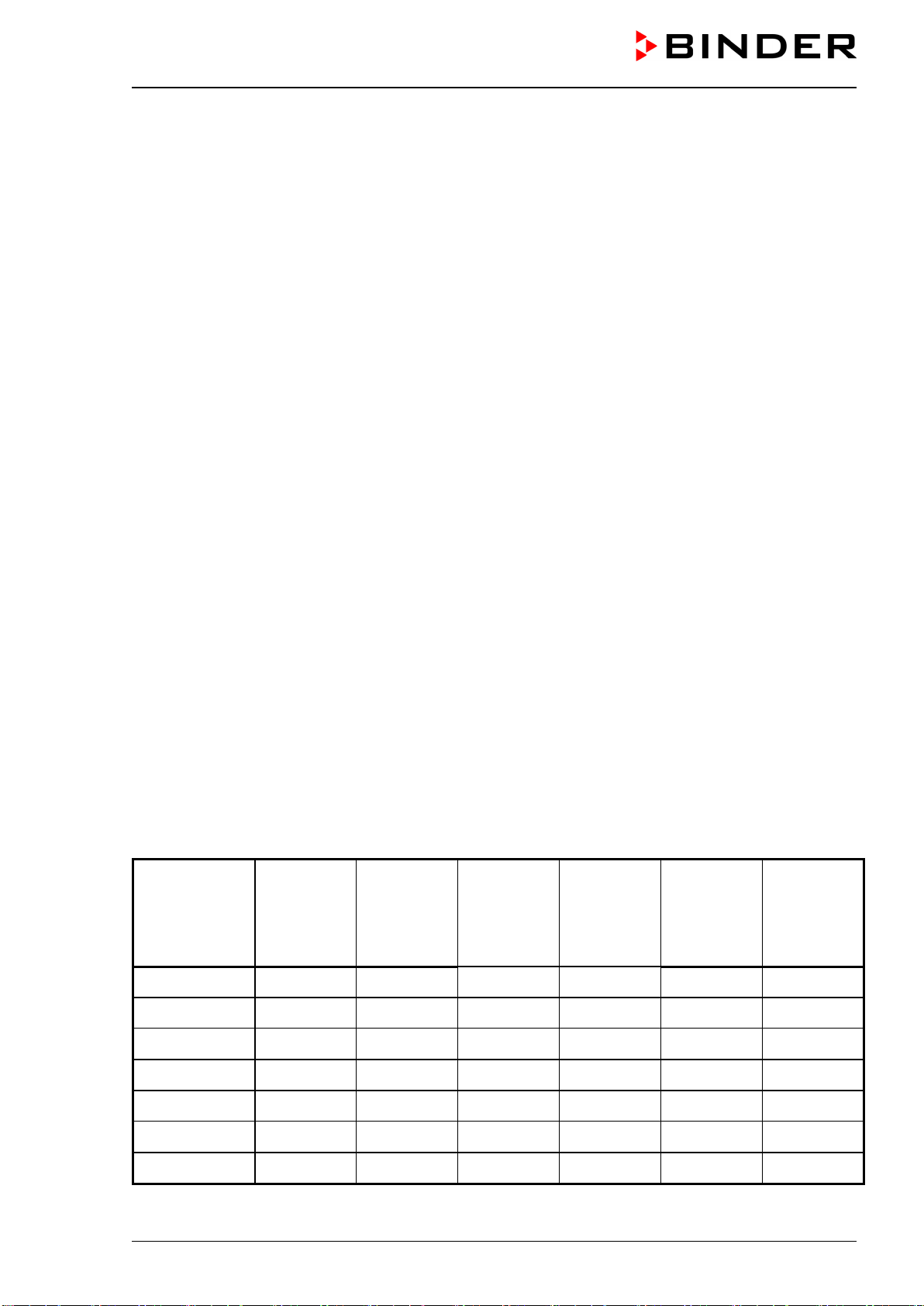

Operation log for the VDL vacuum drying oven

Serial number...............................................

Solvent. In the

case of solvent

mixtures: solvent

with the lowest

Auto-ignition tem-

perature

Auto-ignition

temperature

[unit]

Drying tem-

perature /

temperature

set-point

[unit]

Safety controller

mode

Limit/Offset

Safety control-

ler value [unit]

Date Signature

Loading ...

Loading ...

Loading ...