Loading ...

Loading ...

Loading ...

VDL (E3.1) 10/2020 Page 169/196

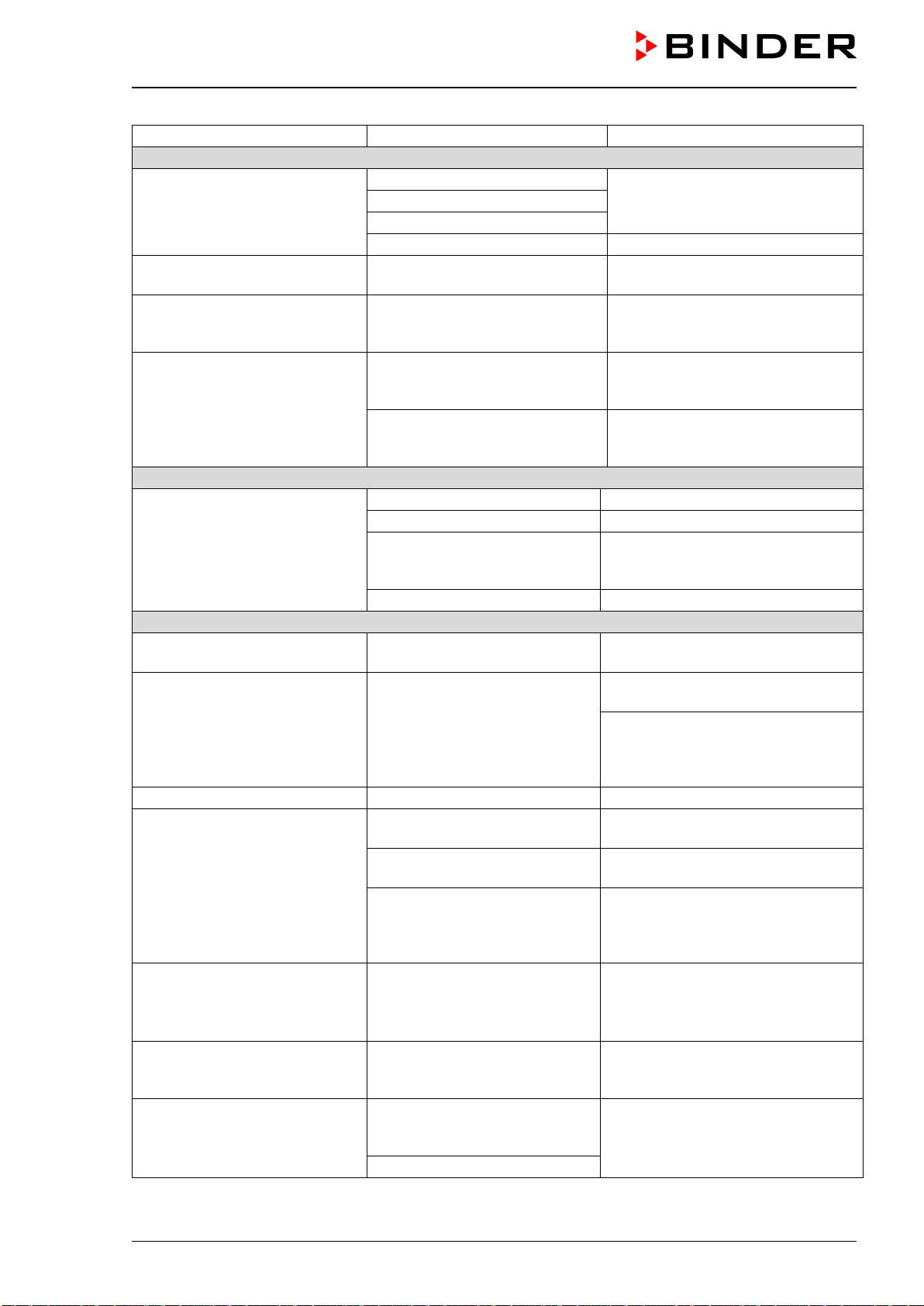

Fault description

Possible cause

Required measures

Heating (continued)

Chamber heating permanently,

set-point not maintained.

Controller defective.

Contact BINDER service

Pt 100 sensor defective.

Semiconductor relay defective

Controller not adjusted.

Calibrate and adjust controller.

Deviations from the indicated

heating-up times.

Oven fully loaded.

Charge the oven less or consider

longer heating-up times.

Deviations from the temperature

set-point in equilibrated state.

Invalid calibration

Use the delivered expansion racks

only. Do NOT change between alu-

minum and stainless-steel racks

Wrong temperature value meas-

ured during calibration

Reference temperature sensor

has insufficient contact to expan-

sion rack.

Fix the reference temperature sen-

sor with thermal conductive paste

or adhesive aluminum tape.

Leakage current when using a

thermo element not electrically

isolated.

Mount a thermo element electrically

isolated from the rack.

Vacuum

Vacuum not held.

Door gasket defective.

Replace door gasket,

Safety glass panel defective.

Replace safety glass panel.

Gaskets of small flange connec-

tions (universal eccentric ring)

defective.

Replace gaskets of small flange

connections.

Inner tube connection leaky.

Contact BINDER Service.

Controller

No chamber function

(dark display).

Chamber is in standby mode.

Deactivate standby mode (chap.

9.5).

Menu functions not available.

Menu functions not available

with current authorization level.

Log in with the required higher au-

thorization.

Log in with the required higher au-

thorization. or contact BINDER ser-

vice to obtain an activation code

(chap. 12.6).

No access to controller

Incorrect password.

Contact BINDER service.

Controller does not equilibrate to

entered setpoints.

Temperature control is turned

off

Turn on temperature control (chap.

11.4).

Pressure control is turned off.

Turn on pressure control (chap.

11.5).

Set-points were entered in

Fixed value operation mode.

Controller is in program opera-

tion mode.

Change to Fixed value operation

mode.

Pressure alarm when operating

without a vacuum connection.

Pressure control turned on.

Turn off pressure control (chap.

11.5).

Acknowledging the alarm does

not cancel the alarm state.

Cause of alarm persists.

Remove cause of alarm. If the alarm

state continues, contact BINDER

service.

Alarm message:

- - - - or <-<-< or >->->

Sensor rupture between sensor

and controller or Pt 100 sensor

defective.

Contact BINDER service.

Short-circuit.

Loading ...

Loading ...

Loading ...