Loading ...

Loading ...

Loading ...

VDL (E3.1) 10/2020 Page 103/196

11.6 Drying monitoring

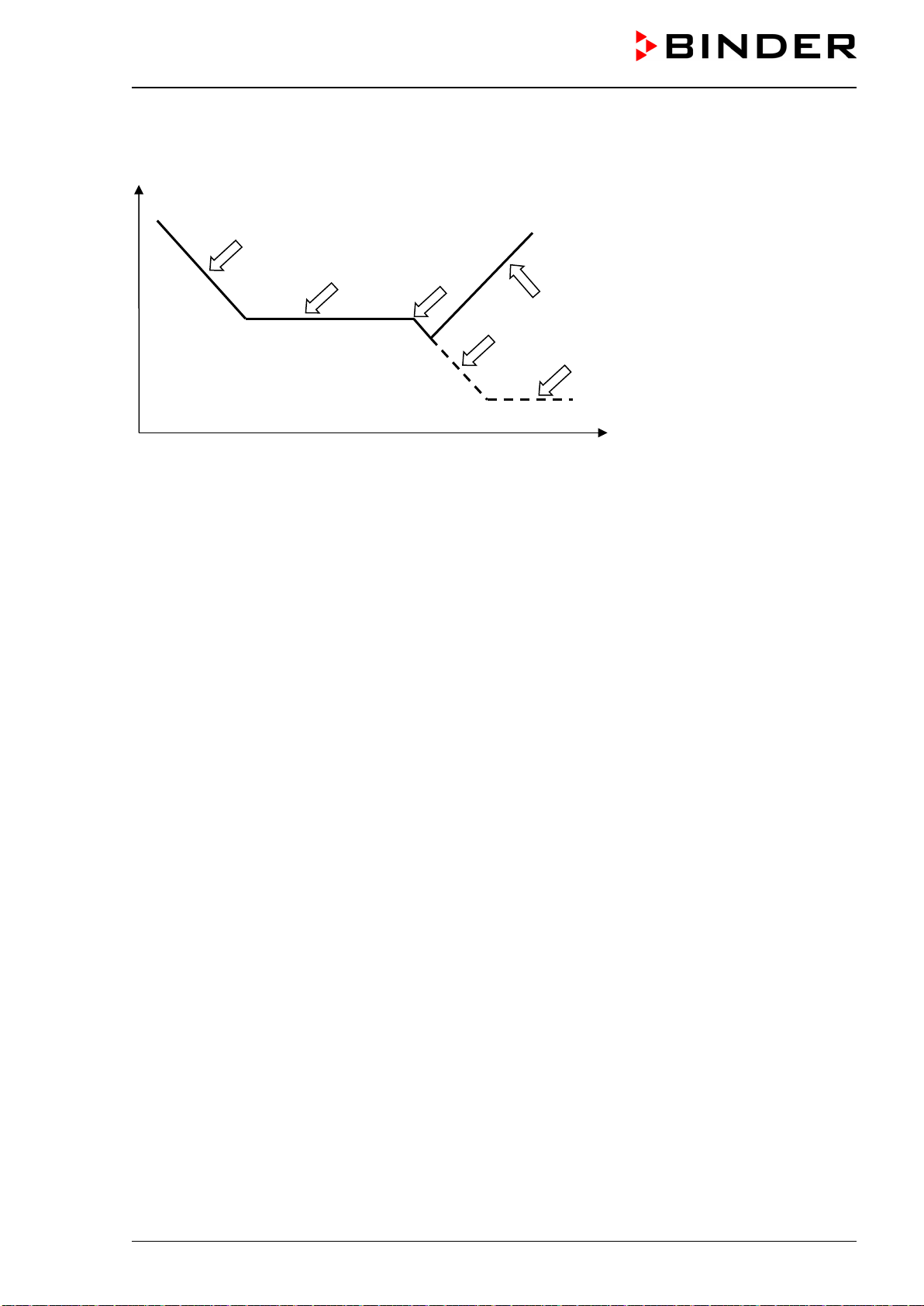

Pressure

Time

Figure 25: Schematic timing of the drying process and drying monitoring

Procedure:

• Enter the temperature set-point.

The previously entered pressure setpoint is not used with this function. It remains saved.

The drying monitoring uses a fixed minimum pressure setpoint.

• Start the drying monitoring: The vacuum pump is activated, the evacuation valve opens.

Starting from ambient pressure, the pressure starts to decrease.

• Depending on the vapor pressure of the solvent, a plateau phase is then reached

during which the

solvent vaporizes. The pressure remains almost constant.

• After the solvent is completely evaporated, drying is complete.

The pressure starts to decrease again

Without drying monitoring the pressure would now continue to decrease

, until the maximum final

vacuum is reached.

• The drying monitoring recognizes this second pressure drop. It turns off the pressure control. The cham-

ber will then be ventilated automatically

.

Prior to starting a new drying process, the pressure control must be activated again (chap. 11.4).

Notes:

If the drying monitoring is aborted during phase

or , the controller will take the current actual pressure

value as the pressure setpoint. This overwrites the previously entered pressure setpoint. It can be changed

manually at any time.

In processes with low temperatures < 40 °C or thermally poorly coupled items to be dried (e.g. drying of

powders), the drying monitoring may incorrectly identify the relevant parameters. In this case, please check

the process result and, if necessary, use a process not including this program for such processes.

Loading ...

Loading ...

Loading ...