Loading ...

Loading ...

Loading ...

XNX Universal Transmitter

Section 3 - Calibration

91

3.2.1 Zero and Span Calibration for XNX EC Sensors,

mV Sensors, and Searchpoint Optima

Caution: Before initial calibration, allow the sensor to stabilize for 30 minutes

after applying power. When in Zero and Span Calibration modes, the current

output from the sensor is inhibited (default 2mA) to avoid false alarms.

Caution: For most sticky gases (e.g., HCl, Cl

2

) use PTFE tubing with short

pieces of rubber tube for the final connection (due to the inflexibility of PTFE). This

minimizes adhesion of the gas to the tube surface and allows more accurate

measurement.

To calibrate the sensor, use an appropriate span gas cylinder,

tubing, magnet, and calibration gas ow housing. Set the ow

regulator to 300-375 ml/min for XNX EC sensors or 500 ±200 ml/

min for XNX mV sensors. A compressed gas cylinder (20.9%Vol

oxygen) should be used to perform the zero calibration if the

area where the sensor is located contains any residual amount

of the target gas. If no residual gas is present, background air

can be used to perform the zero calibration. Contact a Honeywell

Analytics representative for details about suitable calibration kits.

To calibrate the sensor, follow the procedure in Section 3.2.2.

Note: The oxygen sensor does not require a zeroing procedure. Background

air (20.9%Vol oxygen) can be used to span the oxygen sensor in place of a

compressed air cylinder (20.9%Vol oxygen). See Section 6.3.2 for other sensors.

Note: EN performance standards require 10 minutes stabilization time for

application of zero and span gas for performance-approved EC, mV, and IR

sensors prior to calibration.

3.2.2 Calibration Procedure

This section outlines the steps for calibrating the transmitter’s

attached sensors.

Note: The Zero Calibration procedure should be performed prior to the Span

Calibration procedure.

1. If using a compressed gas cylinder, push the calibration

gas ow housing onto the bottom of the sensor and apply

the gas.

2. Access the Gas Calibration Menu.

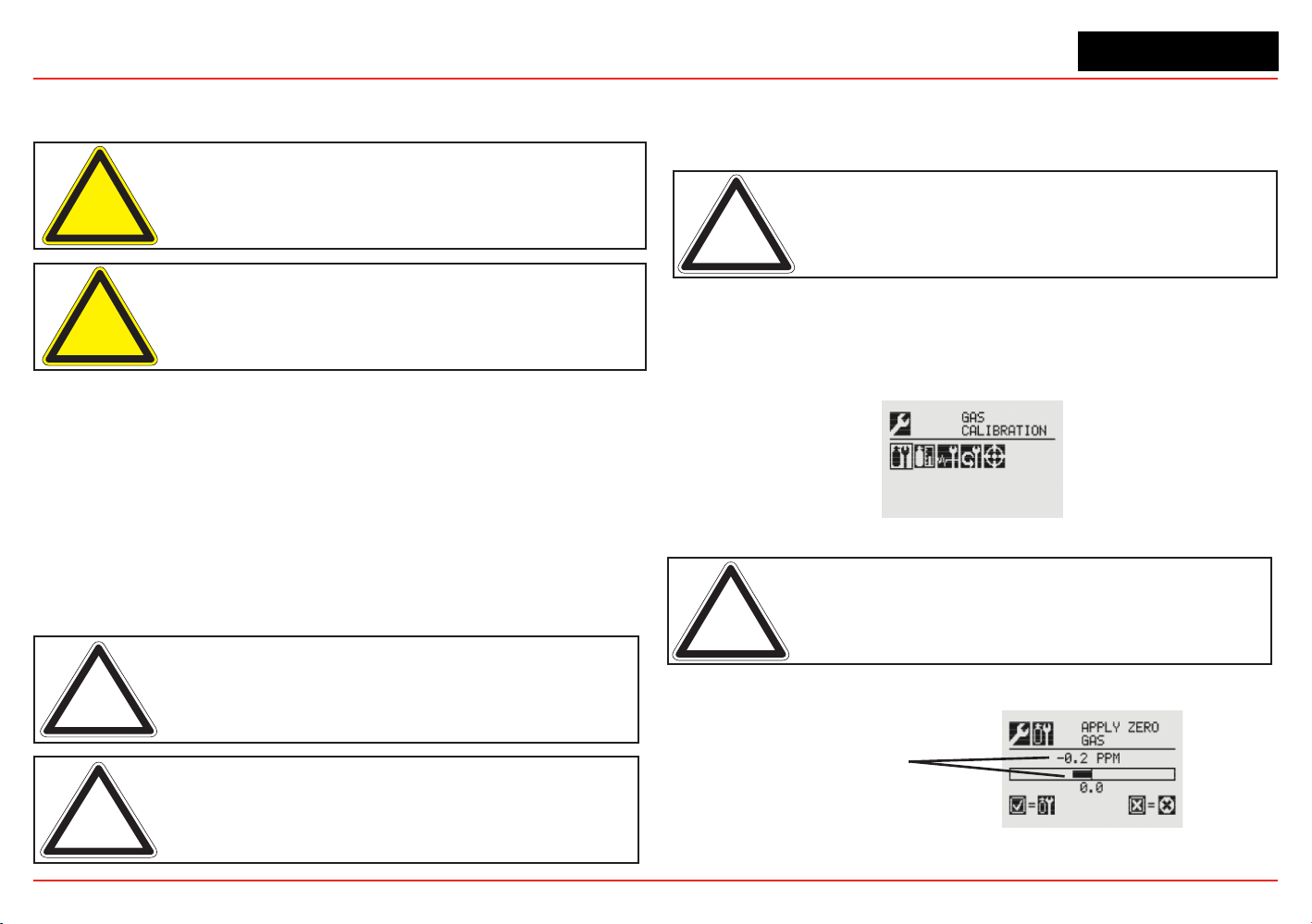

Figure 194. Gas Calibration Menu

Note: The Gas Calibration menu is for both Zero Calibration and Span

Calibration.

Zero Calibration

Sensor Reading

at Current Settings

Figure 195. Zero Calibration Screen

Loading ...

Loading ...

Loading ...