Loading ...

Loading ...

Loading ...

XNX Universal Transmitter

Section 5 - Warnings/Faults

113

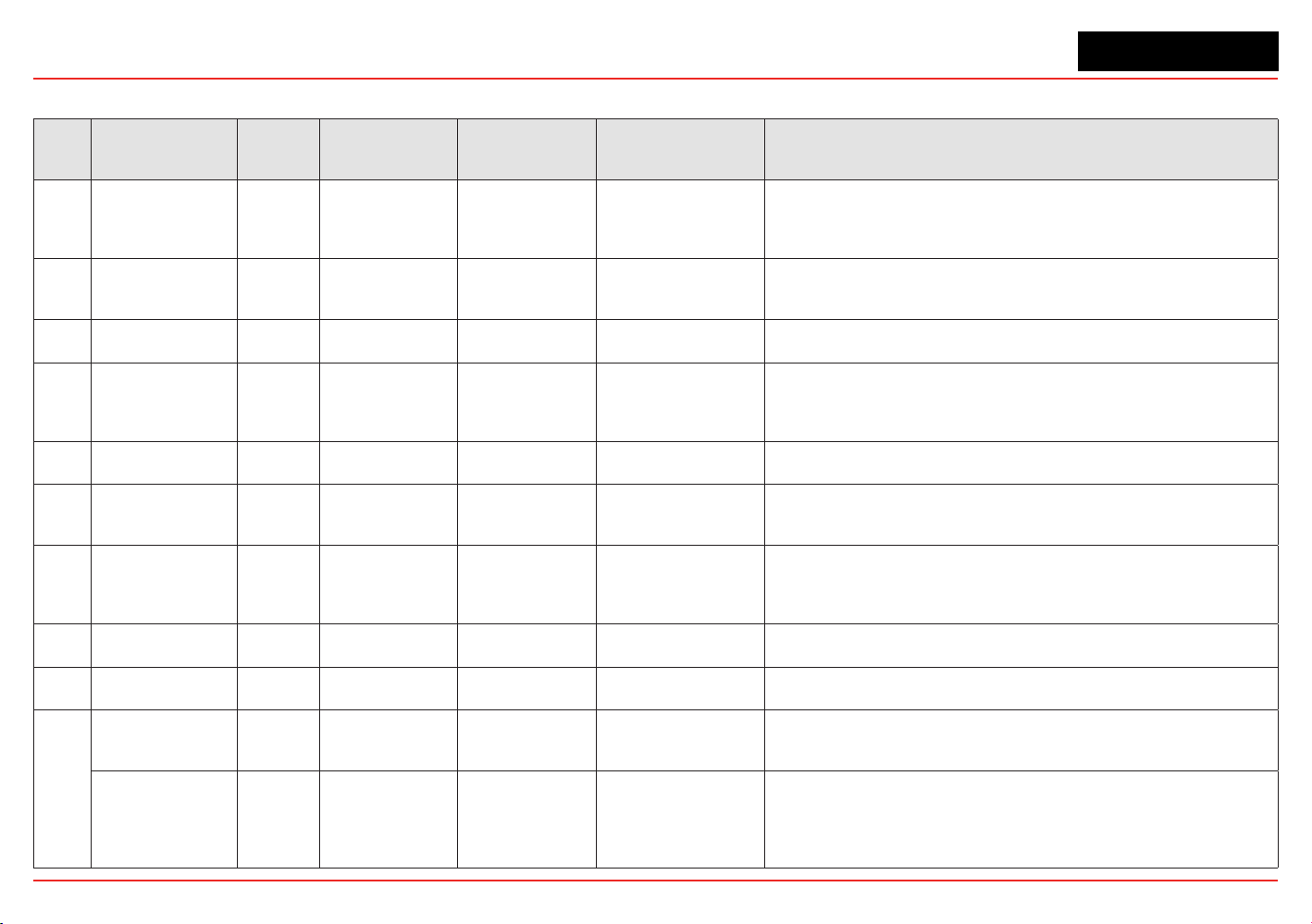

5.2 Fault Messages

Fault Description

Appli-

cable

Sensors

Latching / Non-

Latching

Frequency of

Diagnostic

Event History Data Action For Resolution

F101

Unexpected Sen-

sor Reset

All Non-latching

ECC & mV: main

loop x2;

Optima & Excel: 2

seconds

Note 2. Optima or

Excel: Sensor fault or

warning code (Note 4)

If repeated, check supply voltage, check cable loop impedance, check

terminal connections

F103

XNX Temperature

Error

All Non-latching 2 seconds

XNX temperature

(Celsius)

Check location for heat sources. Fit with sunshade or other protec-

tion. Change the transmitter’s location. Check temperature in Info-

>Transmitter Status to ensure temperature is being measured properly.

F104

XNX 24 VDC Sup-

ply Bad

All Non-latching 2 seconds

XNX supply voltage

x1000

Check the wire of the 24V power supply to the transmitter and the power

supply operation.

F105

3.3VDC Supply

Bad on XNX, per-

sonality board, or

option board

All Non-latching 2 seconds

1=XNX,

2=Personality board,

3=Option board

Check Transmitter Status

F106

XNX Real Time

Clock Failure

All Non-latching 2 seconds

Total seconds since

Jan 1, 1970

Either clock was incorrectly set or the battery for the clock has failed.

Note: the clock will stop running on January 1, 2036.

F107

XNX Internal Fail-

ure (RAM, ROM,

EEPROM, Opcode)

All

Non-latching ex-

cept for EEPROM

error

At power up and

8 hours

Note 3 Contact Honeywell Analytics’ Service Department.

F108

XNX mA Output

Loop Failure

All Latching 2 seconds

mA output error (mea-

sured mA - set mA)

Check wiring of mA output from XNX. Check that switches S1 and S2 are

set correctly. Note that if F108 is not resolved quickly, an F149 (Internal

Communication Failure - mA) will also be generated. When the cause of

F108 is resolved, both the F108 and F149 will be cleared.

F109

Simulated Warn-

ing/Fault

All Non-latching Enabled by user 0 Performing an alarm/fault reset will clear all simulation.

F110

Sensor software

mismatch

Optima Latching

Only checked at

power up

Sensor rmware ver-

sion x10

Contact Honeywell Analytics’ Service Department.

F111

Negative Drift ECC, mV Non-latching 2 seconds

Raw gas concentra-

tion of sensor

Check sensor location for external interference. Perform zero calibra-

tion. If problem persists after zero calibration and no interference exists,

replace sensor.

Negative Drift; may

indicate a failed IR

sensor

Optima,

Excel

Non-latching

XNX polls sensor

every 2 seconds,

diagnostic fre-

quency controlled

by sensor

Sensor fault or warn-

ing code

Check sensor location for external interference. Perform zero calibra-

tion. If problem persists after zero calibration and no interference exists,

replace sensor.

Loading ...

Loading ...

Loading ...