Loading ...

Loading ...

Loading ...

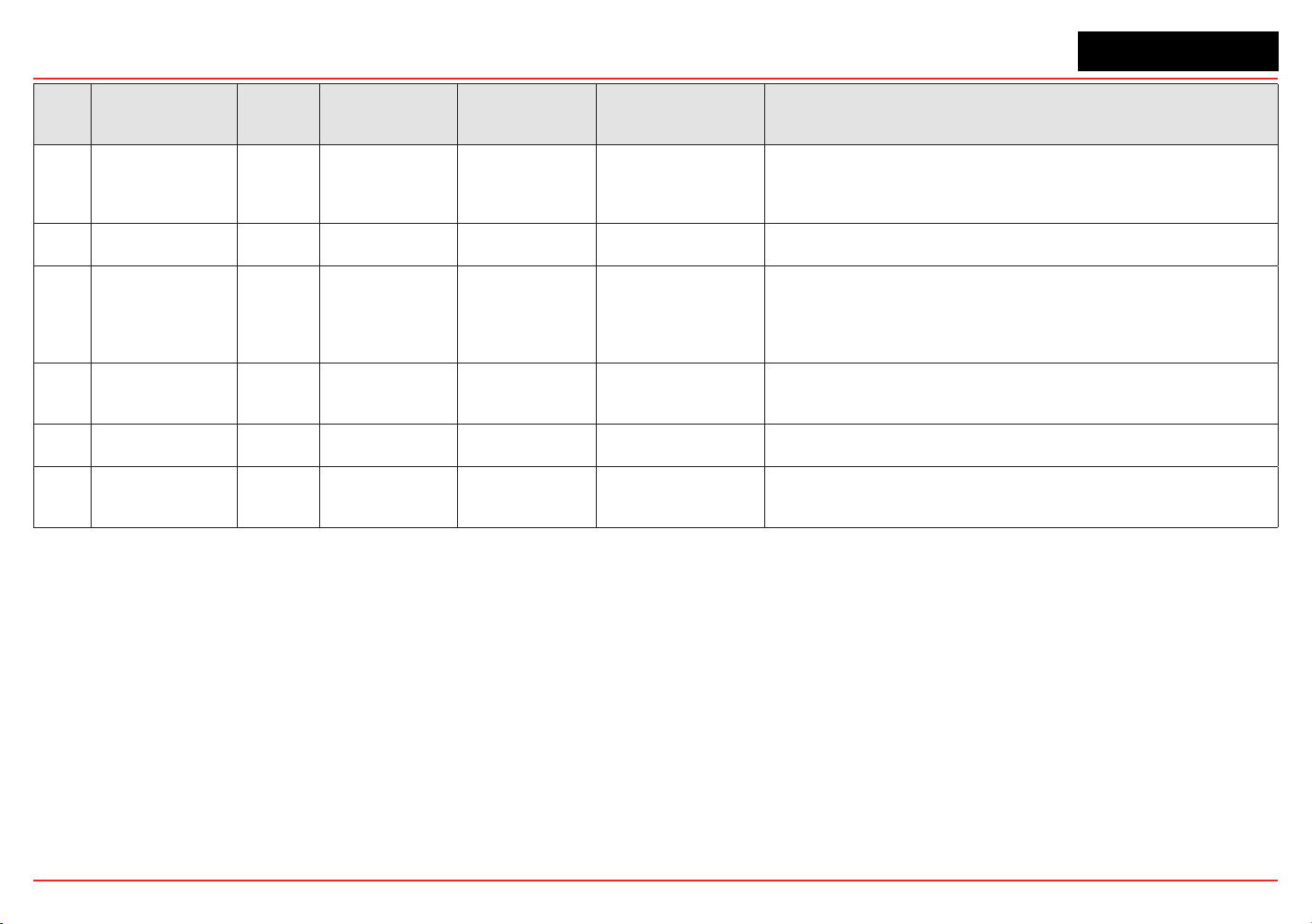

XNX Universal Transmitter

Section 5 - Warnings/Faults

118

Fault Description

Appli-

cable

Sensors

Latching / Non-

Latching

Frequency of

Diagnostic

Event History Data Action For Resolution

F159

Option Part Num-

ber Mismatch

All Non-latching

Only at powerup

or every 125 ms

when no option

board detected

Entire option part #

Check that installed option matches the option indicated in the XNX part

number, check wiring to Optima/Excel.

F160

Hardware Diagnos-

tic Failure

ECC, mV Non-latching Main loop x2

Gain1 high byte,

Gain2 low byte

Replace defective EC cartridge or mV personality board.

F161

mA Input Indicates

Fault

Optima,

Excel

Non-latching 1 second Input mA

Indicates mA input from Optima/Excel is below 1 mA, indicating a fault in

the sensor. Any other fault will also trigger this fault, so check for addi-

tional faults in event history to determine specic issue. If no other faults

indicated, check wiring between Optima/Excel and XNX. Also check that

switches S3 and S4 are set correctly.

F162

Error reloading

safety critical RAM

block

All Non-latching 2 seconds Note 3 Contact Honeywell Analytics’ Service Department.

F163

Interrupt integrity

fault

All Non-latching Main loop Note 3 XNX will reset if more than 600,000 successive errors occur.

F164 mV Sensor failure mV Latching 1 second

mV bridge voltage or

bridge current that

caused fault

Indicates that the sensor was changed or is bad. If the fault will not clear,

replace the sensor.

Loading ...

Loading ...

Loading ...