Loading ...

Loading ...

Loading ...

EN

Fiorenzato | Series_00 Ed. 04/2022

11 / 49

Series

EN

When using the machine, no other work or activities are permitted which are considered

to be improper and which, in general, may involve risks in terms of user safety and/or

damage to the machine.

Reasonably foreseeable misuse includes:

- Using the machine for grinding products other than roasted coffee beans

(e.g. pepper, salt, etc.).

- Using the appliance with pre-ground coffee.

- Improper use of the appliance by personnel who have not been trained to use it

and/or have not read this instruction manual.

- Using spare parts that are not original and/or not specifi cally for the grinder-

doser model in your possession.

- Using the machine in a potentially explosive environment.

In addition, the user must never under any circumstances:

- Attempt to remove any foreign objects that may have accidentally fallen into

the coffee feed hopper and/or grinding chamber without fi rst disconnecting the

appliance from the mains power supply.

- Use the appliance with wet or damp hands.

- Introduce liquids of any kind into the coffee feed hopper and the grinding chamber.

If the machine is not working properly, any necessary steps are the

responsibility of the maintenance technicians.

3.3 Precautions for proper and safe use

In order to ensure user safety and to operate the appliance in the best possible way,

it is important to comply with some simple but important provisions, namely:

- Avoid improper use of the power cable. Use only cables or extensions with a

cross-section suitable for the power installed in the machine.

- Protect the cable from high temperatures, oil and sharp edges.

- Any changes in normal operation (increased power absorption, a rise in

temperature, excessive vibration, abnormal noises or alarm signals on the

display) indicate improper operation. In order to prevent malfunctioning, which

may directly or indirectly cause damage to people or the appliance, ensure you

carry out the required maintenance or, if necessary, contact your dealer or a

specialised repairer.

- Heavy appliance! Be careful during the phases of transport, handling and

installation! Please refer to chapter 4 for proper handling of the appliance.

Fiorenzato | Series_00 Ed. 04/2022

12 / 49

EN

Series

3.4 Safety devices on the grinder-doser

All grinder-dosers manufactured by Fiorenzato M.C. S.r.l. are equipped with

appropriate mechanical and electromechanical devices to protect the safety

of the user and the integrity/functionality of the appliance during use.

The grinder-dosers in the

series are equipped with the following safety devices:

• Motor thermal cut-out: The motor of the appliance has a thermal cut-out which

protects it against overheating due to overcurrents and intervenes by interrupting

the power supply to the motor.

• Cooling fan (Fig. 3): Only the grinder-doser models F64 EVO and F71 EK have a

cooling fan on the back of the machine body to prevent overheating of the grinding

blade drive motor. This fan is activated electronically. Start-up is enabled when

communication between the coffee grinder and the weight calculation software has

terminated.

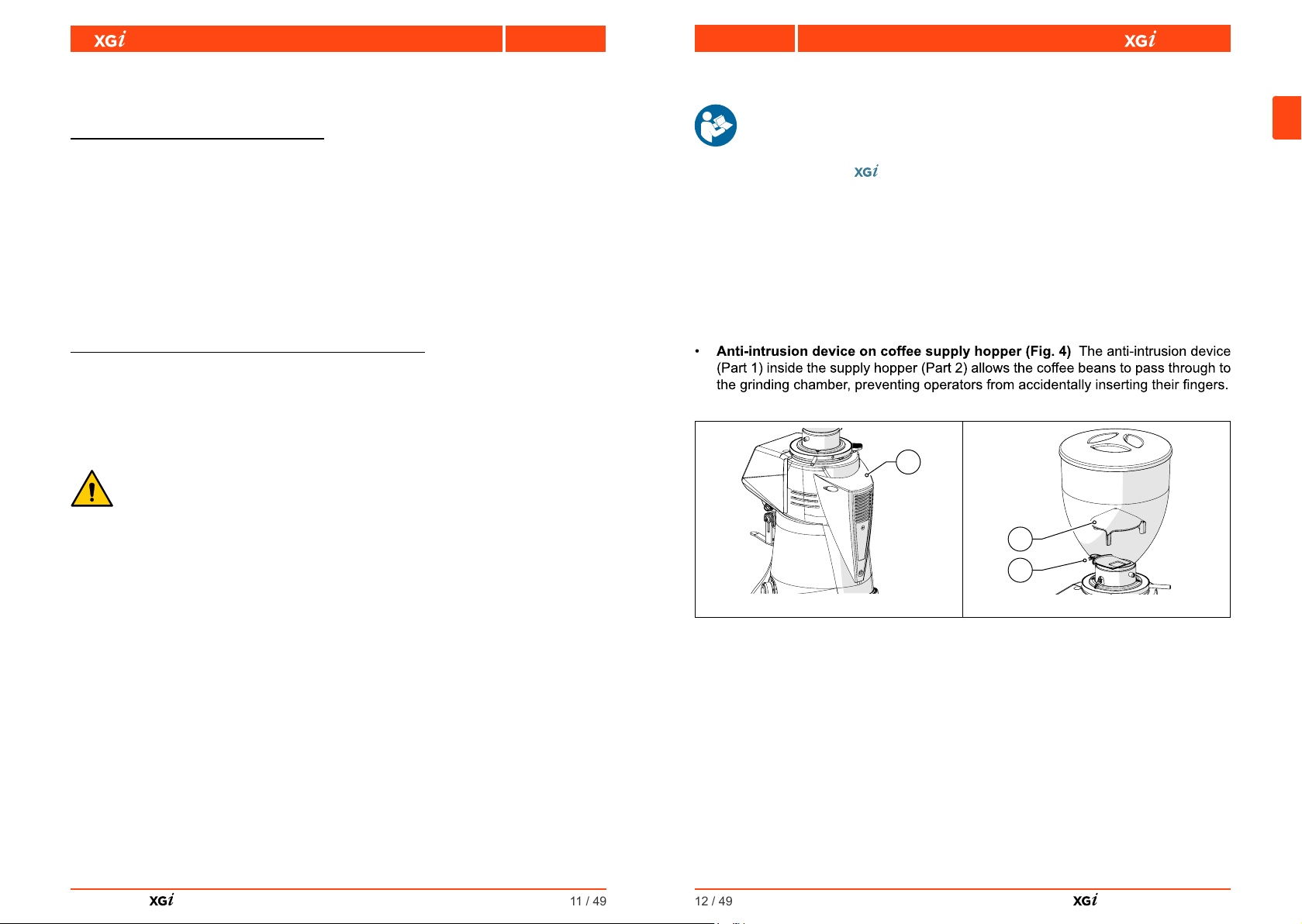

• Anti-intrusion device on coffee supply hopper (Fig. 4): The anti-intrusion device

(Part 1) inside the supply hopper (Part 2) allows the coffee beans to pass through to

the grinding chamber, preventing operators from accidentally inserting their fi ngers.

1

1

2

Fig. 3 Fig. 4

• Safety adjustment disk lock lever (Fig. 5): To prevent any accidental rotation of

the grinding adjustment disk (Part 1), there is an adjustment disk lock lever (Part 2)

which must be pressed to allow rotation.

• Microswitch for detection of grinding degree variation (Fig. 6): This microswitch

(Part 1), enabled each time the lock lever is pressed (Part 2), is used to inform the

control system that a change in the grinding degree may have occurred since the

last dose was dispensed and enables the “Dispense dose” mode.

Loading ...

Loading ...

Loading ...