Loading ...

Loading ...

Loading ...

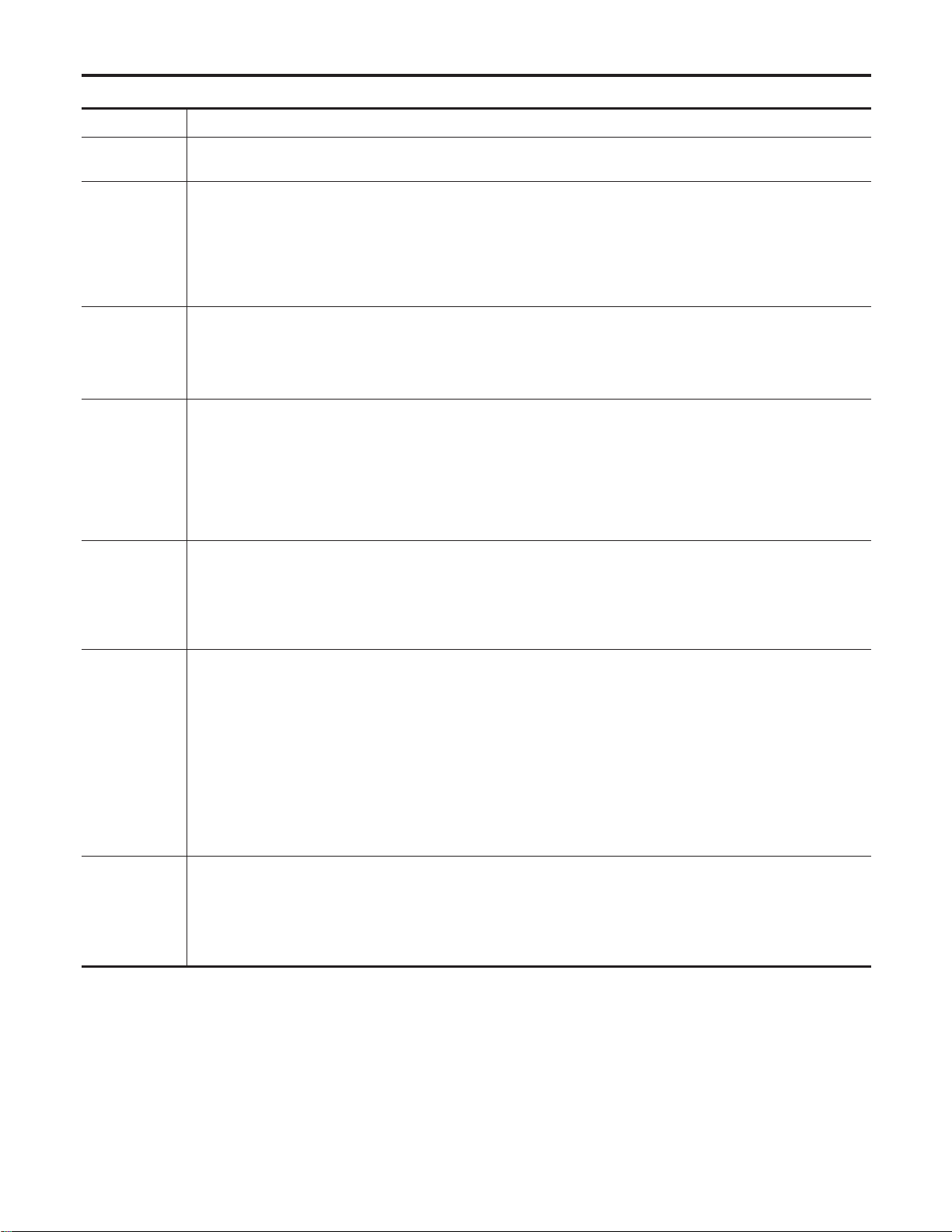

DESCRIPTION FOR WORK FLOW

NFEC0037S01

STEP DESCRIPTION

STEP I

Get detailed information about the conditions and the environment when the incident/symptom occurred using

the “DIAGNOSTIC WORK SHEET”, EC-120.

STEP II

Before confirming the concern, check and write down (print out using CONSULT-II or GST) the (1st trip) DTC

and the (1st trip) freeze frame data, then erase the DTC and the data. (Refer to EC-91.) The (1st trip) DTC and

the (1st trip) freeze frame data can be used when duplicating the incident at STEP III & IV.

If the incident cannot be verified, perform “TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT”, EC-156.

Study the relationship between the cause, specified by (1st trip) DTC, and the symptom described by the cus-

tomer. (The “Symptom Matrix Chart” will be useful. See EC-131.)

Also check related service bulletins for information.

STEP III

Try to confirm the symptom and under what conditions the incident occurs.

The “DIAGNOSTIC WORK SHEET” and the freeze frame data are useful to verify the incident. Connect CON-

SULT-II to the vehicle in DATA MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform “TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT”, EC-156.

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IV

Try to detect the (1st trip) DTC by driving in (or performing) the “DTC Confirmation Procedure”. Check and read

the (1st trip) DTC and (1st trip) freeze frame data by using CONSULT-II or GST.

During the (1st trip) DTC verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR (AUTO

TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform “TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT”, EC-156.

In case the “DTC Confirmation Procedure” is not available, perform the “Overall Function Check” instead. The

(1st trip) DTC cannot be displayed by this check, however, this simplified “check” is an effective alternative.

The “NG” result of the “Overall Function Check” is the same as the (1st trip) DTC detection.

STEP V

Take the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to TROUBLE DIAGNOSIS FOR DTC PXXXX.

If the normal code is indicated, proceed to the BASIC INSPECTION. (Refer to EC-123.) If CONSULT-II is

available, perform “DATA MONITOR (SPEC)” mode with CONSULT-II and proceed to the “TROUBLE DIAGNO-

SIS — SPECIFICATION VALUE”, EC-152. (If malfunction is detected, proceed to “REPAIR REPLACE”.) Then

perform inspections according to the Symptom Matrix Chart. (Refer to EC-131.)

STEP VI

Identify where to begin diagnosis based on the relationship study between symptom and possible causes.

Inspect the system for mechanical binding, loose connectors or wiring damage using (tracing) “Harness Layouts”.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in “DATA MONITOR

(AUTO TRIG)” mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CON-

SULT-II. Refer to EC-135, 141.

The “Diagnostic Procedure” in EC section contains a description based on open circuit inspection. A short circuit

inspection is also required for the circuit check in the Diagnostic Procedure. For details, refer to GI-22, “Circuit

Inspection”.

Repair or replace the malfunction parts.

If malfunctioning part cannot be detected, perform “TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT”,

EC-156.

STEP VII

Once you have repaired the circuit or replaced a component, you need to run the engine in the same conditions

and circumstances which resulted in the customer’s initial complaint.

Perform the “DTC Confirmation Procedure” and confirm the normal code [DTC No. P0000] is detected. If the

incident is still detected in the final check, perform STEP VI by using a different method from the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) (1st trip) DTC in

ECM and TCM (Transmission control module). (Refer to EC-91.)

TROUBLE DIAGNOSIS — INTRODUCTION

Work Flow (Cont’d)

EC-122

Loading ...

Loading ...

Loading ...