Loading ...

Loading ...

Loading ...

Once a tyre pressure of 2.0–2.5 bar is achieved, con-

tinue the journey at a maximum speed of 80 km/h

(50 mph).

›

Avoid full accelerations, strong braking and fast

cornering.

Information for driving with repaired tyres

›

The pressure of the repaired tyre must be checked

after driving for 10 minutes.

›

If the tyre pressure is 1.3 bar and less, do not con-

tinue! Seek the help of a specialist garage.

›

If the tyre pressure is higher than 1.3 bar, correct

the pressure to the correct value of at least 2 bar

and continue driving.

NOTICE

Danger of damage to the compressor!

▶

After the maximum running time of the air com-

pressor, allow it to cool for a few minutes.

WARNING

Risk of burns!

The tyre inflation hose and the air compressor may

become hot when inflated.

▶

Allow the air compressor and hose to cool for a

few minutes.

Usage restrictions

Do not use the kit in the following cases.

▶

The rim is damaged.

▶

The outdoor temperature is below the minimum

temperature indicated in the manual of the tyre fill-

ing bottle.

▶

Tyre punctures are greater than 4 mm.

▶

There is damage to the tyre wall.

▶

The expiry date stated on the tyre inflation bottle

has expired.

Self-help

Seal the tyres

›

Unscrew the valve cap from the damaged tyre.

›

Unscrew the valve core with the valve insert and

place it on a clean surface.

›

Shake the tyre inflation bottle back and forth with

sealant.

›

Screw the inflation hose onto the tyre inflater bot-

tle. The film on the closure is pierced automatically.

›

Remove the plug from the inflation hose and push

it fully onto the tyre valve.

›

Hold the bottle with the bottom facing upwards

and fill all of the sealing agent into the tyre.

›

Remove the filler plug from the valve.

›

Screw in the valve insert.

Inflate

tyres

›

Fit the tyre inflation hose of the air compressor to

the tyre valve.

›

Secure the vehicle with the parking brake.

›

Start the engine.

›

Plug the connector into the 12 volt socket .

›

Turn on the air compressor.

›

Once a tyre pressure of 2.0-2.5 bar is reached, turn

o the air compressor.

Observe the maximum running time of the air com-

pressor according to the directions of the repair kit

manufacturer.

›

If an air pressure of 2.0 - 2.5 bar has not been

reached, remove the tyre inflation hose from the

valve.

›

Drive approx. 10 metres forwards or backwards to

allow the sealing agent to distribute in the tyre.

›

Replace the tire inflation hose on the valve and re-

peat the inflation procedure.

Tyre pressure

What you should be mindful of

NOTICE

▶

Always adjust the tyre pressure to the load.

▶

Check the pressure in all tyres at least once a

month and before each longer ride.

▶

Check the pressure when the tyres are cold. If nec-

essary, do not reduce the elevated pressure when

the tyres are warm.

▶

After each tyre pressure change, save the new val-

ues in the tyre pressure monitoring system.

WARNING

Risk of an accident!

If tyre pressure loss is very quick, try to stop the ve-

hicle carefully without heavy steering or heavy brak-

ing.

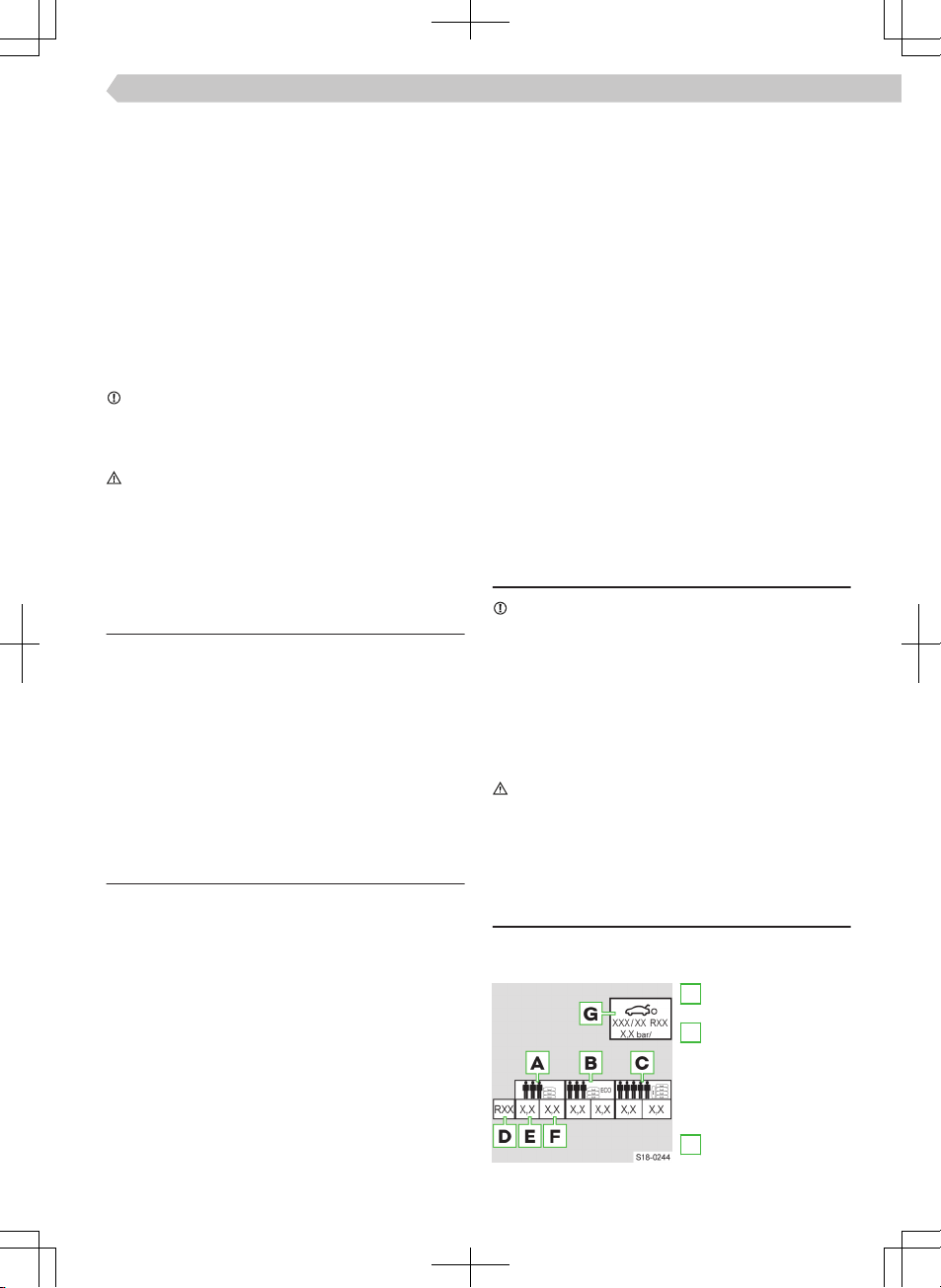

Sticker with prescribed tyre pressures

The sticker with prescribed tyre pressures is located

on the inside of the fuel filler flap.

A

Inflation pressure for

half load

B

Inflation pressure for

environmentally

friendly operation

(slightly lower fuel

consumption and

emissions)

C

Inflation pressure for

full load

149

Wheels › Tyre pressure

Loading ...

Loading ...

Loading ...