Loading ...

Loading ...

Loading ...

CB / CB-UL, CBF / CBF-UL (E7) 07/2021 Page 24/197

2. Chamber description

The CO

2

incubators CB / CB-UL and CBF / CBF-UL are equipped with a multifunctional microprocessor

display controller for temperature, CO

2

, and O

2

(chamber with O

2

control) levels and humidity (CBF / CBF-

UL) and a digital display accurate to one-tenth of a degree resp. 0.1 vol.-%. With its comprehensive program

control functions, the display program controller MB2 permits the high precision performance of

temperature, CO

2

, O

2

(chamber with O

2

control), and humidity (CBF / CBF-UL) cycles.

Material: The inner chamber, the pre-heating chamber and the inside of the doors are all made of stainless

steel V2A (German material no. 1.4301, US equivalent AISI 304). The inner surfaces are smooth and

therefore easy to clean. The inner chamber is deep-drawn from one piece, polished (suitable for

pharmaceutical applications) and has no welds or inaccessible corners. The hinges and the seal of the

inner glass door are glued from the outside to aid cleaning of the inner chamber. When operating the

chamber at high temperatures (sterilization), the impact of the oxygen in the air may cause discoloration of

the metallic surfaces (yellowish-brown or blue) by natural oxidation processes. These colorations are

harmless and will in no way impair the function or quality of the chamber. The perforated shelves are also

made of stainless steel. You can insert a maximum of 3 (chamber size 56), 6 (chamber size 170), resp. 8

(chamber size 220) shelves. The housing is RAL 7035 powder-coated. All corners and edges are also

completely coated.

Door lock: The DuoDoor™ door lock offers two to open the outer door and glass door independently or

together. The outer door is regularly equipped with a door lock with keys. The standard chamber door is

hinged right. The chamber is optionally available with door hinged left.

Sterilization: The chamber’s heating system permits hot-air auto-sterilization at a setpoint of 180 °C /

356 °F. Thus, the effective sterilization temperature is maintained for at least two hours on all internal

surfaces, resulting in sterilization of the entire inner chamber. The effectiveness of the sterilization has also

been confirmed by an independent research institute.

Temperature safety device Thanks to the regular safety controller (temperature safety device class 3.1

acc. to DIN 12880:2007), the set temperature is maintained in case of failure.

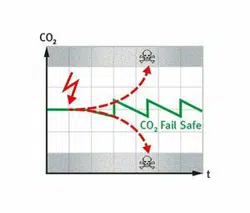

CO

2

system: A highly precise, drift-free CO

2

infrared measuring system in combination with the permanent

mixture of CO

2

gas through a special proprietary gas mixing head developed by BINDER allows precise

and constant CO

2

concentrations for long periods. This creates optimum growth conditions for cultures.

The gas enters the chamber via a fine filter (aseptic filter) with a high filtration efficiency that also filters the

smallest particles.

Fast reaction times, maximum accuracy and selectivity characterize the CO

2

measuring procedure of the

CO

2

incubators. The accuracy of the CO

2

measuring system is based on an infrared measuring cell with

NDIR (non-dispersive infrared) sensor, which continuously regulates to a reference value. Therefore,

disturbance variables and aging phenomena in the measuring system are almost completely eliminated,

so that this measuring system, in contrast to other measuring procedures, remains practically drift-free

between calibrations and is entirely selective for CO

2

. The sensor is built into the chamber and can be

sterilized.

O

2

control (chamber with O

2

control): The CO

2

incubator is available with O

2

control in addition to CO

2

control. There are two different control ranges:

• Regular equipment: Hypoxic control range 0.2 to 20 vol. % O

2

. Only N

2

can be connected to reduce O

2

concentration; it is not possible to connect O

2

gas bottles to increase O

2

concentration. Control in the

low O

2

range is very precise, in particular in the range below 1 vol. % O

2

.

• Alternative control range 10 to 95 vol. % O

2

(option). Although the high control range is intended in

particular for hyperoxic applications (> 21 vol. % O

2

), it is also suitable for slightly hypoxic applications

between 10 and 20 vol. % O

2

.

The O

2

sensor is a semiconductor gas sensor with ZrO

2

ceramic.

Loading ...

Loading ...

Loading ...