Loading ...

Loading ...

Loading ...

CB / CB-UL, CBF / CBF-UL (E7) 07/2021 Page 171/197

22.6.7 Humidity (CBF / CBF-UL)

Fault description

Possible cause

Required measures

Humidity fluctuation:

Control accuracy of +/- 3 %

r.h. is not reached.

Door gasket defective.

Replace door gasket.

Door opened very frequently. Open doors less frequently.

Humidity fluctuation, together

with temperature fluctuation

> 1 °C with a set-point approx.

3 °C above ambient

temperature.

Place of installation too hot.

Select cooler place of installation or

contact BINDER service.

Alarm message “Humidity

system”.

Humidity module defective.

Acknowledge the alarm on the

controller. Contact BINDER service.

Alarm message “Freshwater

supply”.

Freshwater bag is empty or

contains air.

Acknowledge the alarm on the

controller. Fill the freshwater bag

correctly.

The silicon tube is not correctly

inserted into the pump.

Acknowledge the alarm on the

controller.

Place the silicon tube correctly (chap.

4.5.2).

Silicon tube kinked.

Too high humidity inside the

chamber (exceeding the set-

point)

Ambient humidity too high at

site of installation

Possible dehumidification depends on

ambient humidity. Select installation

site with lower humidity.

22.6.8 Controller

Fault description

Possible cause

Required measures

No chamber function

(dark display).

Display in standby mode.

Press on touchscreen.

Main power switch turned off.

Turn on the main power switch.

Menu functions not available.

Menu functions not available

with current authorization level.

Log in with the required higher

authorization. or contact BINDER

service to obtain an activation code

(chap. 13.6).

No access to controller

Password incorrect.

Contact BINDER service.

Chart recorder function:

measured-value memory

cleared; information lost.

New setting of storage rate or

scaling (minimum and/or

maximum) (chap. 16.2).

Change the storage rate or scaling

ONLY if the previously registered data

are no longer required.

Controller does not equilibrate

to setpoints entered in Fixed

value operation mode

Controller is not in Fixed value

operation mode.

Change to Fixed value operation

mode.

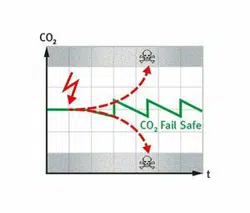

CO

2

control is deactivated.

Activate CO

2

control (chap. 6.7).

Chamber with O

2

control:

O

2

control is deactivated.

Activate O

2

control (chap. 6.7).

CBF / CBF-UL: Humidity

control is deactivated.

Activate humidity control (chap. 6.7).

Controller does not equilibrate

to program set-points.

Controller is not in program

operation mode, or program

delay time is running.

Start the program again. If

appropriate, wait for the program

delay time.

Program duration longer than

programmed.

Tolerances have been

programmed.

For rapid transition phases, do NOT

program tolerance limits in order to

permit maximum speed for heating,

gas control or humidification.

Loading ...

Loading ...

Loading ...