Loading ...

Loading ...

Loading ...

Engine Servicing

4-25

4-25

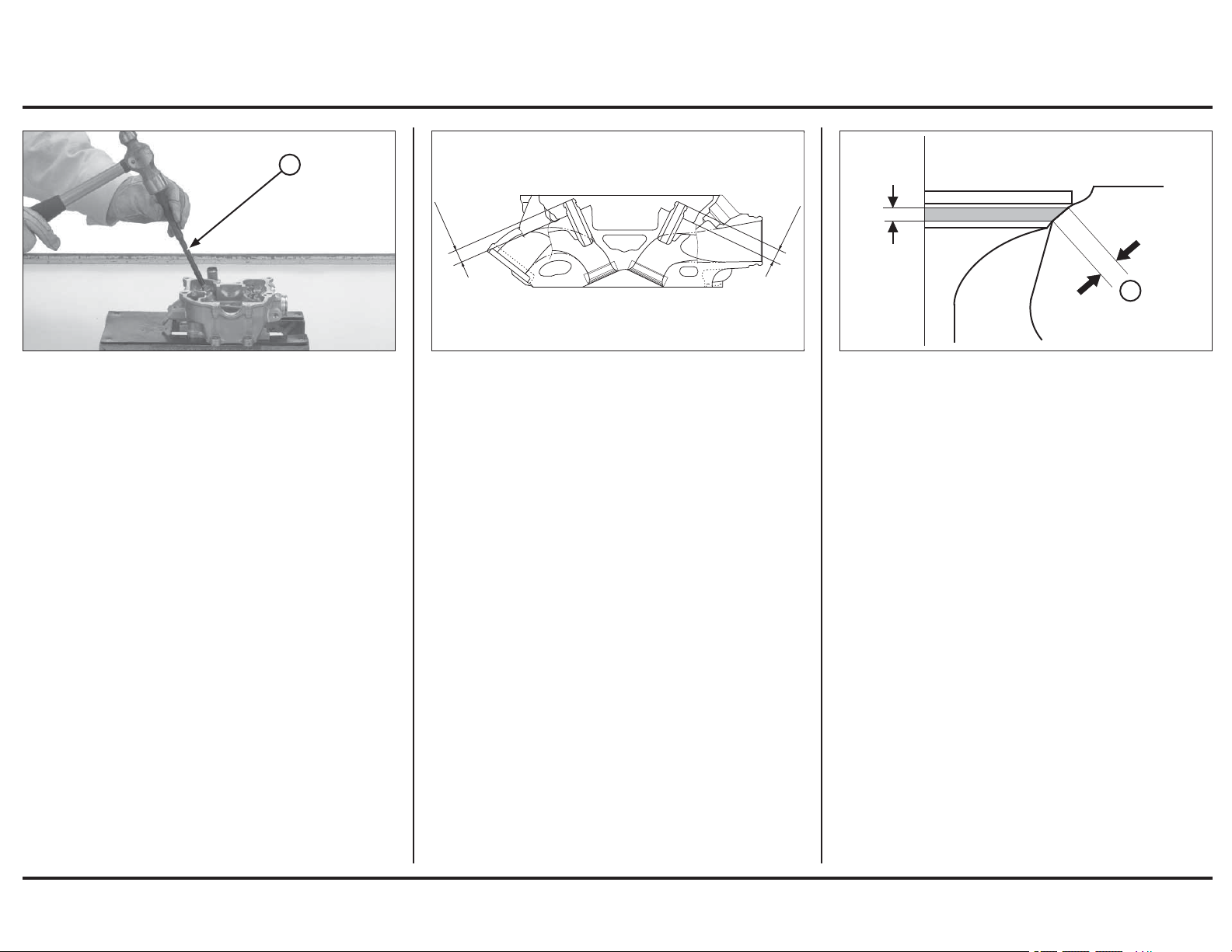

Valve Seat Inspection/Refacing

Clean the intake and exhaust valves thoroughly to remove

carbon deposits.

Apply a light coating of Prussian Blue to the valve seat.

Tap the valves and seats using a rubber hose or other

hand lapping tool.

Remove the valve and inspect the valve seat face.

The valve seat contact should be within the specified

width and even all around the circumference.

Standard:

IN/EX: 0.9 – 1.1 mm (0.035 – 0.043 in)

Service limit:

IN/EX: 1.7 mm (0.07 in)

If the seat width is not within specification, reface the

valve seat (page 4-26).

Inspect the valve seat face for:

y Uneven seat width:

– Replace the valve and reface the valve seat.

y Damaged face:

– Replace the valve and reface the valve seat.

(1) VALVE SEAT WIDTH

Check that the valve guides are at the proper depth using

a slide caliper, adjust the height if necessary.

Specified depth:

IN: 8.0 – 8.3 mm (0.31 – 0.33 in)

EX: 8.2 – 8.5 mm (0.32 – 0.33 in)

Let the cylinder head cool to room temperature.

Ream the new valve guides.

Insert the reamer from the combustion chamber side of

the cylinder head and always rotate the reamer clockwise.

Use cutting oil on the reamer during this operation.

Take care not to tilt or lean the reamer in the guide while

reaming.

Tool:

Valve guide reamer, 4.508 mm 07HMH–ML0010B

Clean the cylinder head thoroughly to remove any metal

particles after reaming and refacing the valve seats.

Remove the guide from the freezer.

While the cylinder head is still heated, drive new valve

guides into the cylinder head from the top of the cylinder

(camshaft side).

Drive the guides until the marks are parallel with the

cylinder head.

Tool:

Valve guide driver 07HMD–ML00101

(1) VALVE GUIDE DRIVER

1

1

Loading ...

Loading ...

Loading ...