Loading ...

Loading ...

Loading ...

Fig. 133

4. Holding the wrench and arm in position

rotate yoke to a non-preset position and

rotate swivel lock to the locked position. If the

yoke can still be moved the square nut has not

been tightened enough. Repeat step 3.

5. When the adjustment is such that the yoke

can no longer be moved when the swivel lock

is in the locked position. Install the two

screws.

6. Unlock swivel arm and rotate yoke to a

non-preset position. Return yoke to a rip

position. If the index pin does not securely

seat at the preset position, the adjustment is

too tight. Remove the two screws and loosen

the square nut one quarter turn until swivel

index pin seats securely.

7. Adjustment is complete when both locking

and preset position functions are working

properly.

8. Re-install the two screws mounting the

wrench portion of the swivel lock.

9. Re-install knob to swivel handle and install

screw and nut in knob.

Arm and Column

With the miter lock unlocked and in the unin-

dexed position the arm should fit snugly to

the column tube and not allow any vertical

movement. If you can move the end of the

arm up and down an adjustment is needed.

1. With a #2 Phillips screwdriver remove two

screws and the rear arm cover.

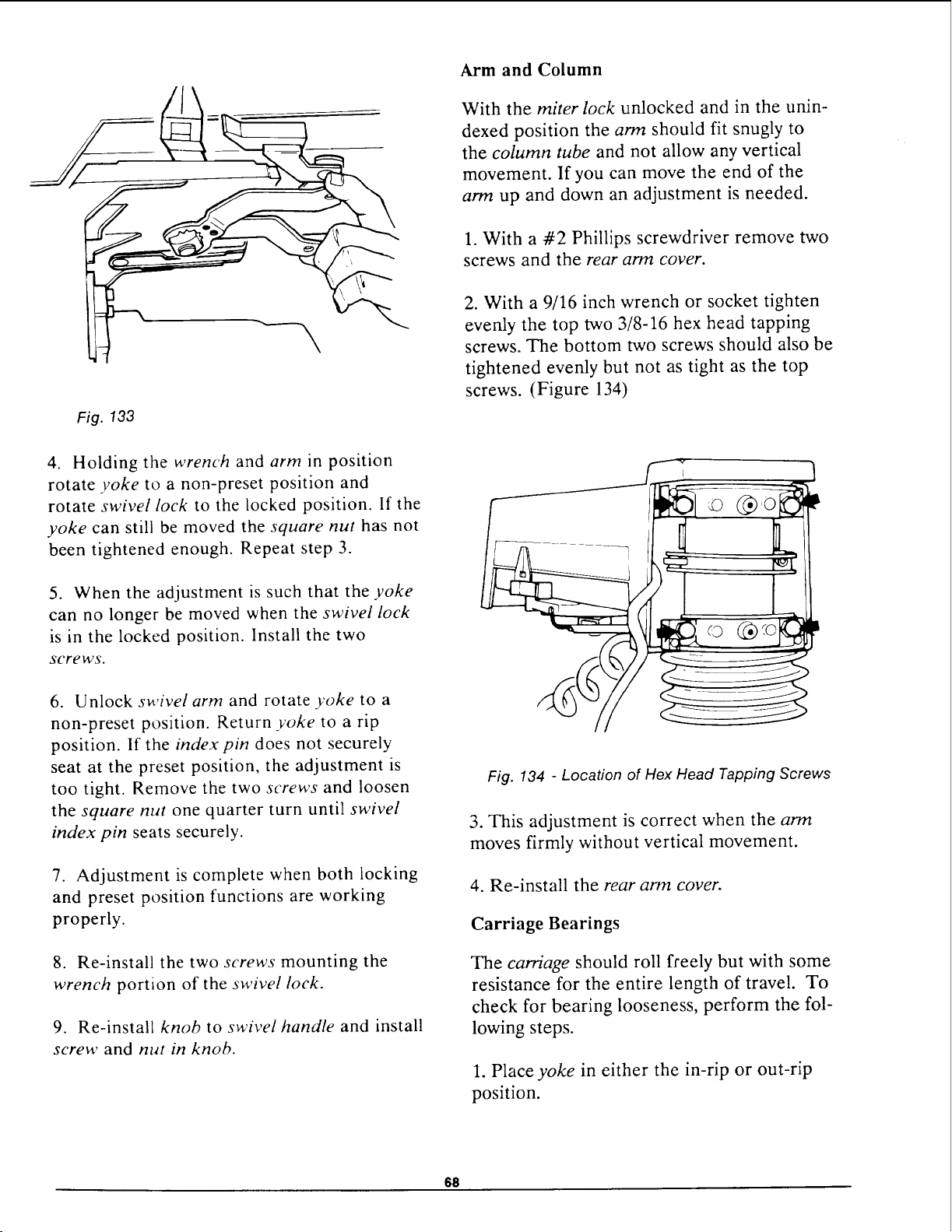

2. With a 9/16 inch wrench or socket tighten

evenly the top two 3/8-16 hex head tapping

screws. The bottom two screws should also be

tightened evenly but not as tight as the top

screws. (Figure 134)

© @o

Fig. 134 - Location of Hex Head Tapping Screws

3. This adjustment is correct when the arm

moves firmly without vertical movement.

4. Re-install the rear arm cover.

Carriage Bearings

The carriage should roll freely but with some

resistance for the entire length of travel. To

check for bearing looseness, perform the fol-

lowing steps.

1. Place yoke in either the in-rip or out-rip

position.

611

Loading ...

Loading ...

Loading ...