Loading ...

Loading ...

Loading ...

• Lubricate the cam surfaces of the rip

lock assembly.

• A light film of oil should be wiped on

the face of the column tube to lubricate

the fit between the column tube and

column support. With elevation hand-

wheel raise arm to upper limit.

.The thread on the elevation shaft as-

sembly can be lubricated through the

oil hole in the center of the radial arm

cap. Lubricate ramp on the swivel index

spring.

Fig. 129- Swivel and Bevel Index Pins

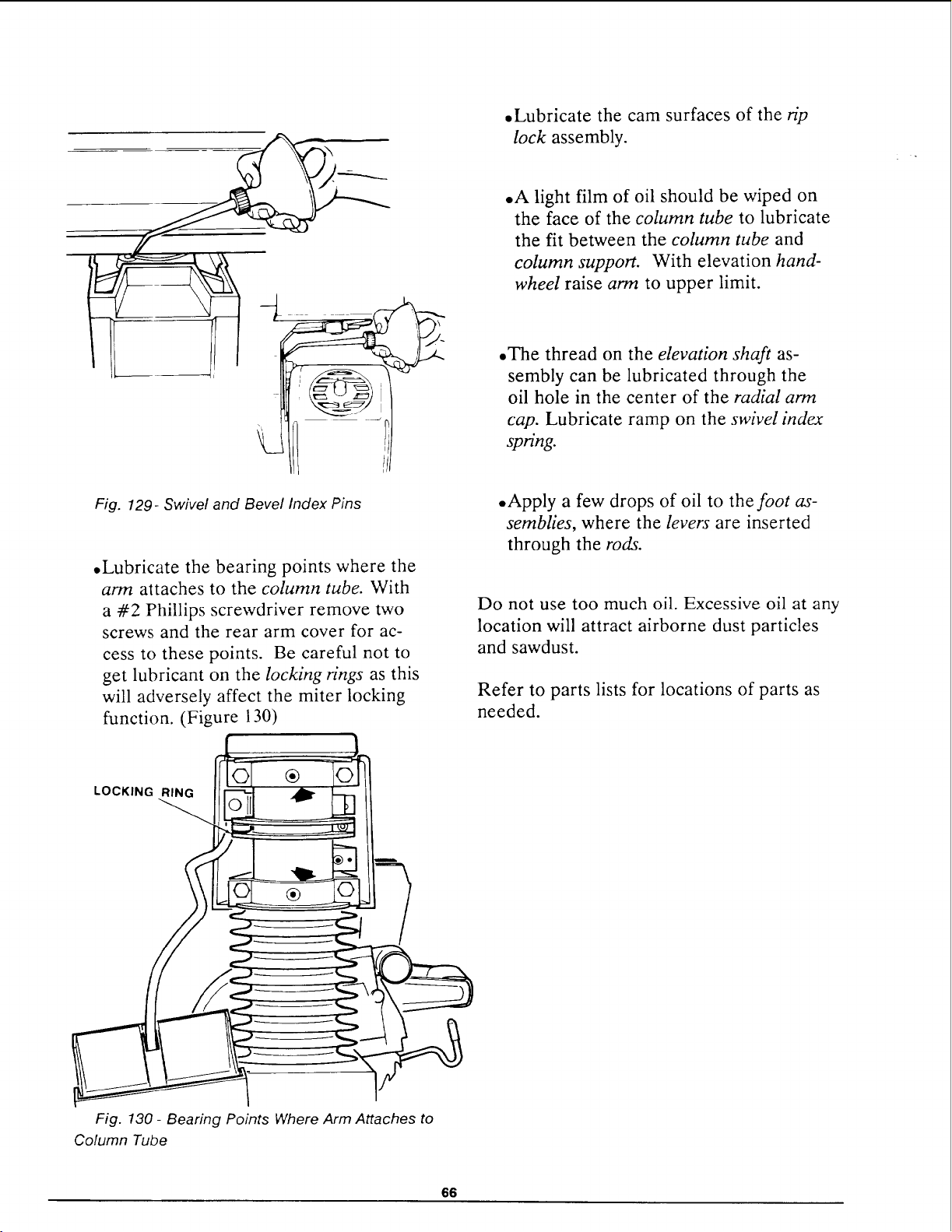

.Lubricate the bearing points where the

arm attaches to the column tube. With

a #2 Phillips screwdriver remove two

screws and the rear arm cover for ac-

cess to these points. Be careful not to

get lubricant on the locking rings as this

will adversely affect the miter locking

function. (Figure 130)

• Apply a few drops of oil to the foot as-

semblies, where the levers are inserted

through the rods.

Do not use too much oil. Excessive oil at any

location will attract airborne dust particles

and sawdust.

Refer to parts lists for locations of parts as

needed.

LOCKING RING

®

Fig. 130 - Bearing Points Where Arm Attaches to

Column Tube

66

Loading ...

Loading ...

Loading ...