Loading ...

Loading ...

Loading ...

14.Rip workpieces that are longer than the

diameter of the blade being used.Do not rip

a workpiece that is shorter than the diameter

of the blade being used.

15.Cut only one workpiece at a time. Do

not cut stackedworkpieces or lay them edge

to edgefor cutting.

Workpiece Support Safety

1. Use additional supports for workpieces

which extend beyond the saw table. Large

workpieces can shift, twist, rise from table or

fall after they are cut.

2. Helpers can be hit by a thrown workpiece,

workpiece chips or pieces of the blade. Use

table extensions or other supports. Do not

use helpers.

3. Helpers can cause the workpiece to kick-

back. Do not use other people to support or

assist in feeding or pulling the workpiece.

Use table extensions. See Recommended Ac-

cessories section of the manual.

4. When table extensions over 24 inches wide

are added to either side of the saw, make

sure you either bolt the saw to the floor or

support the outer end of the extension from

the floor with sturdy legs or an outrigger.

Blade Safety

1. Use blades marked for 3450 rpm or higher.

2. Do not use blades larger than l0 inches in

diameter.

3. Keep blade sharp and clean.

4. Do not cycle motor switch on and off rapid-

ly; the blade can loosen.

5. Do not overtighten the blade; the blade

collar can be warped.

Safety Labels on the Radial Arm Saw

The following labels are on your radial arm

saw. Locate, read and follow the safety in-

structions and information contained in these

labels.

1. Wrong way feed label located on the out-

feed end of the blade guard.

r

I DANGER J

TO AVOID

INJURY DO NOT

FEED MATERIAL

INTO CUTTING

TOOL FROM

THIS END

Fig. 7 Wrong Way Feed Label

2. Safety instruction label located on the

front of the saw near the handwheel.

Fig. 8

[ DANGER I

FOR YOUR OWN SAFETY:

1. Read and understand owner's manual

before operating machine.

2. Wear safety goggles complying with

ANSIZ87.t.

3. Keep hands out of path of saw blade.

4. Know how to avoid "KICKBACKS_'

5. Use "PUSH STICK" for narrow work.

6. Never reach around the saw blade.

7. Never perform any operation

"FREEHAND:'

8. Return carriage to the full rear position

after each cross-cut type operation.

9. Shut off power and allow saw blade to

stop before adjusting or servicing.

Safety Instruction Label

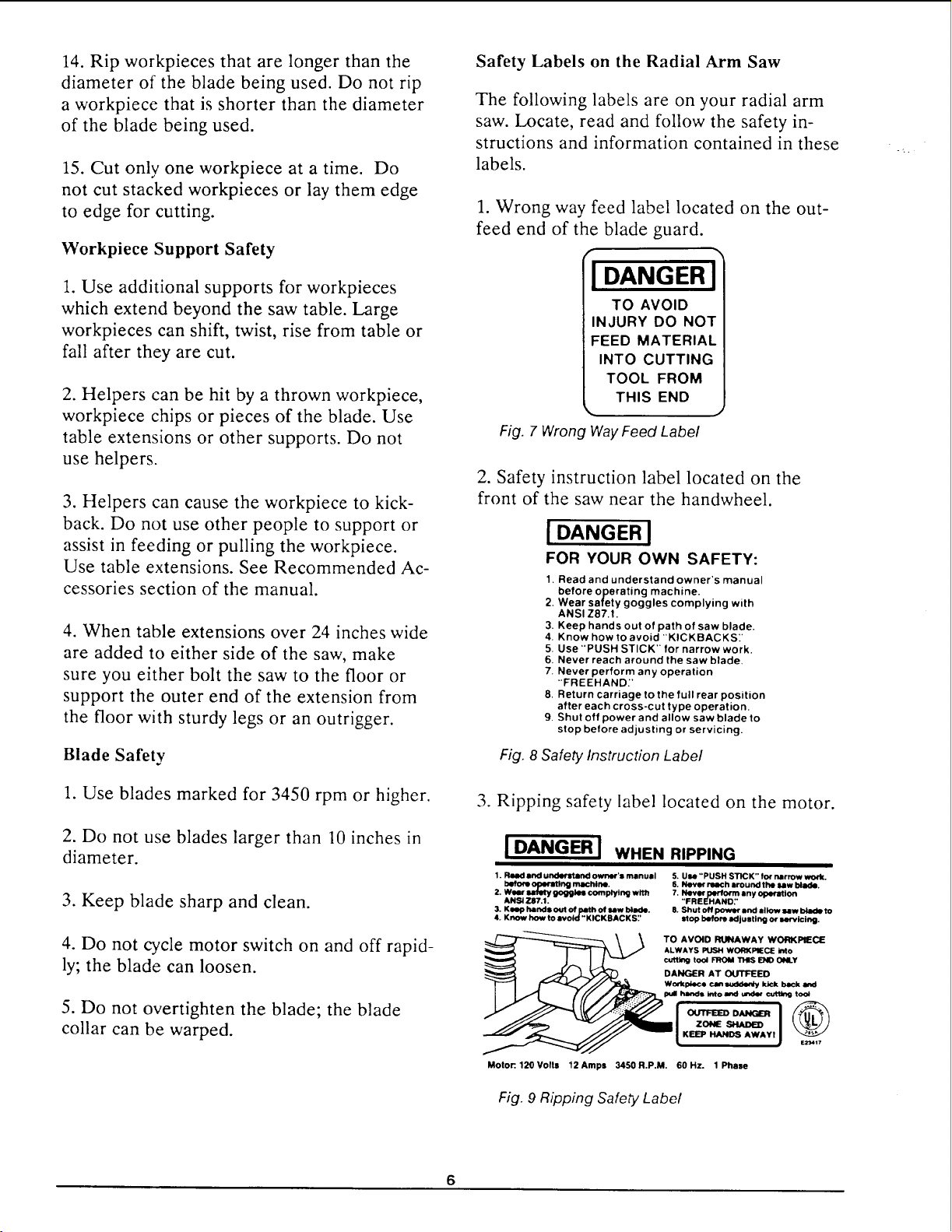

3. Ripping safety label located on the motor.

IDANGERI

WHEN RIPPING

1. Read and understand owner's manual

operaUng m4_blne.

2. Woar salfMy goggles complying with

ANSi 7.87.1.

3. KINIp hands out of path of law bllide.

4. Know how to avoid "KICKBACKS:'

5. Use "PUSH STICK" for narrow work.

6. Nero" roach around the law blade.

7. Never perform any oporatlon

"FREEHAND:'

8. Shut o4/power and allow law blade to

StOp before adjusting o¢ N/'_'lclng.

TO AVOID RUNAWAY WORKPIECE

ALWAYS PUSH WO_,KPIIECE into

cutt_ tool FROM THIS END ONLY

DANGER AT OUTFEED

Wotkpleca can smlck_ kick beck and

, and under out_ too_

ZONE

KEEP HANDS AWAYI

e._d417

Motor:. 120 Volts 12 Amps 3450 R.P.M. 60 Hz. 1 Phase

Fig. 9 Ripping Safety Label

Loading ...

Loading ...

Loading ...