Loading ...

Loading ...

Loading ...

Making Blade Parallel to

Table

These steps are done to help prevent the

workpiece from being thrown or damaged

when the saw is used for edging.

/

>,,,,,/--,il _ Ld aYi.._P_

I'1 '_", I I II-_P] -'_ ,r'--%

I I IV'-" I

k___!_, I I LI b ==_! I

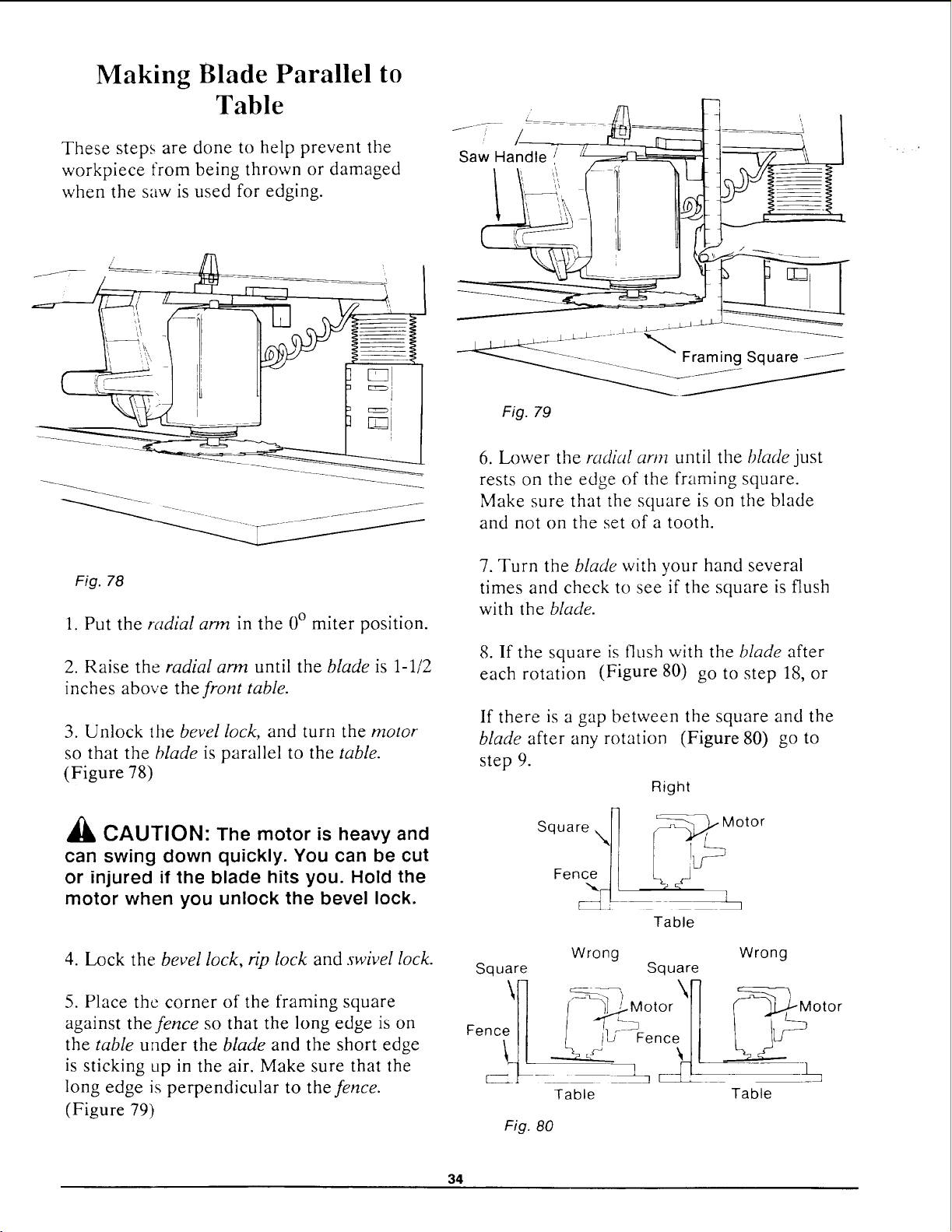

Fig. 78

1. Put the radial arm in the 0 ° miter position.

2. Raise the radial arm until the blade is 1-1/2

inches above the front table.

3. Unlock the bevel lock, and turn the motor

so that the blade is parallel to the table.

(Figure 78)

,_ CAUTION: The motor is heavy and

can swing down quickly. You can be cut

or injured if the blade hits you. Hold the

motor when you unlock the bevel lock.

4. Lock the bevel lock, rip lock and swivel lock.

5. Place the corner of the framing square

against the fence so that the long edge is on

the table under the blade and the short edge

is sticking up in the air. Make sure that the

long edge is perpendicular to the fence.

(Figure 79)

J-;:- /_............ _

Saw Ha

-__ _--_- -: _- _" Framing Square

Fig. 79

6. Lower the radial arm until the blade just

rests on the edge of the framing square.

Make sure that the square is on the blade

and not on the set of a tooth.

7. Turn the blade with your hand several

times and check to see if the square is flush

with the blade.

8. If the square is flush with the blade after

each rotation (Figure 80) go to step 18, or

If there is a gap between the square and the

blade after any rotation (Figure 80) go to

step 9.

Right

Square "X_ _ Motor

Table

Square

Fe_l

Wrong Wrong

Square

/__tOr\nc_i ] __M°t°r

Table Table

Fig. 80

34

Loading ...

Loading ...

Loading ...