Loading ...

Loading ...

Loading ...

THt Mechanism

turning _ctior_ c_ be _,'.:iius_ed by _gMer_i__g or ioose<_ing

the screws in the bea,*i_!_ r_:_aim>_

NOTE: Ti!t har_dw_eei must be removed to adiust. W__,e_"_

adjusting the sc!ews i_ the bea_i,qg retainer, ho_d the nut

fftside using a 3'8 _ch wrench.

Maintaining Your TaMe Saw

Maintenance

WARNING: For your own safety, turn switch "OFF" ]

and remove plug from power source outget before

J

maintaining or tJubr_cating your .saw.

• Do not altow sawdust to accumulate ip,side the saw,

Frequently Mow out any dust that may accumulate

ff'_side the saw cabinet a__d the motor.

o Clean your cutting tools with a gurn and pitch remover,

o The cord and the too_ should be wiped with a dry clean

cloth to prevent deterioration from oil and grease.

• A ceat of automobiie4ype wax appiied to the table wiJi

he_p to keep the surface clean and aIIow wo_kpieces to

s_ide more freely.

o tf the power cord is worn cut or damaged in any way

have it replaced irnmediately,

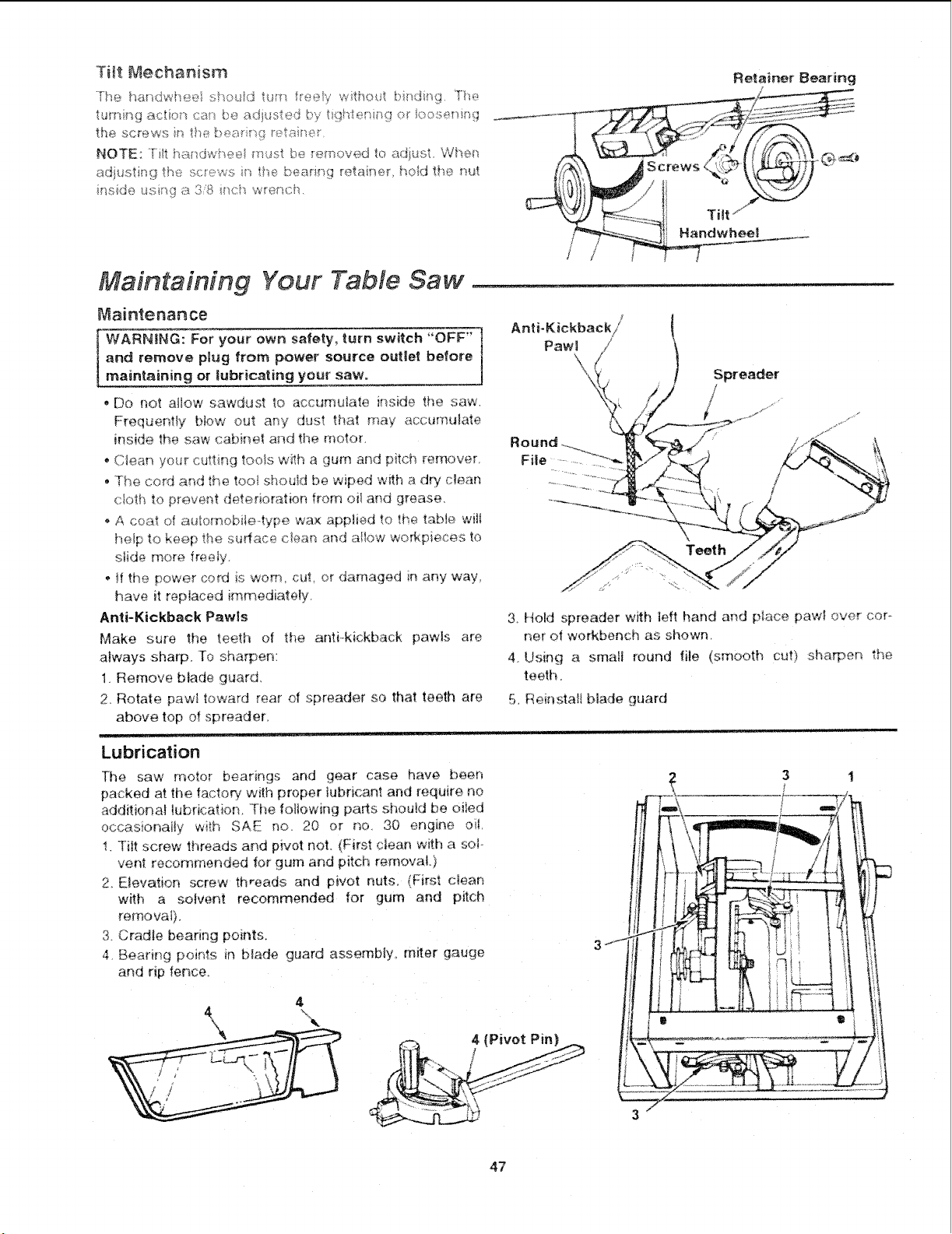

Anti-Kickback Paw_s

Make sure the teeth of the anti-kickback pawls are

always sharp. To sharpen:

1. Remove blade guard,

2. Rotate paw_ toward rear of spreader so that teeth are

above top of spreader.

Re_ainer _earring

_'_T _

i / _i e

._ ]i Tilt"

dwheel

Anti-Kickback//

Pawl /

X!

Teeth

Spreader

3. Hold spreader with left hand and place pawl over cop

ne_ of workbench as shown,

4, Using a smalt round file (smooth cut) sha_en the

teeth.

5, Reinstafl btade guard

Lubrication

The saw motor bearings and gear case have been

packed at the factory with proper lubricant and requffe no

additiona! tubricatior_. The following parts should be oiled

occasionai@ with SAE no. 20 or no. 30 engine oil.

1 Tiff screw threads and p_vot not. _First cJean with a sop

vent recommended fo_ gum and pitch removal }

2. E_evatien screw threads and pivot nuts, _Firsl c_ean

wffh a so_ven_ recommended for gum and pitch

removaI_

3 Cradle bearing points.

4 Bearing pomps _n blade guard assembly, m_ter gauge

and Np ter_ce,

dr-.,, 4 (Pivot Pin)

4

\

3"

47

Loading ...

Loading ...

Loading ...