Loading ...

Loading ...

Loading ...

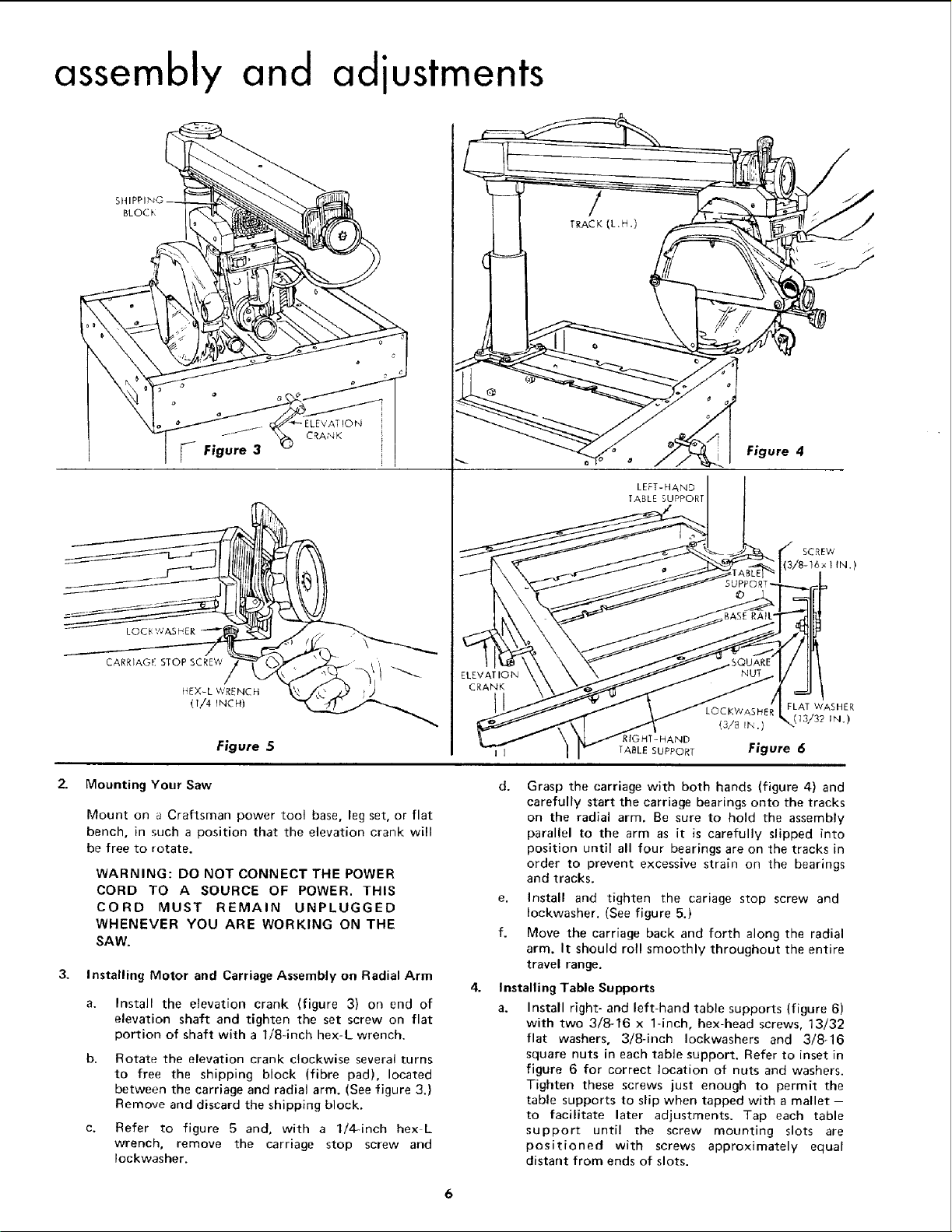

assembly and adjustments

BLOCK

CARRIAGE STOP SCREW

14EX-L WRENCH _ .)

0/4 rNCH)

Figure 5

LEFT-HAND

TABLE SUPPORT

I [ TABLE SUPPORf

Figure 4

SCREW

3/8-16 x I IN.)

2.. Mounting Your Saw

Mount on a CrafLsman power tool base, leg set, or flat

bench, in such a position that the elevation crank will

be free to rotate.

WARNING: DO NOT CONNECT THE POWER

CORD TO A SOURCE OF POWER, THIS

CORD MUST REMAIN UNPLUGGED

WHENEVER YOU ARE WORKING ON THE

SAW.

3, Installing Motor and Carriage Assembly on Radial Arm

Install the elevation crank (figure 3} on end of

elevation shaft and tighten the set screw on flat

portion of shaft with a 1/8-inch hex-L wrench.

Rotate the elevation crank clockwise several turns

to free the shipping block (fibre pad), located

between the carriage and radial arm. (See figure 3.)

Remove and discard the shipping block.

Refer to figure 5 and, with a 1/4-inch hex L

wrench, remove the carriage stop screw and

Iockwasher.

LOCKWASHER FLAT WASHER

(13/32 IN.)

(3/8 In .)

Figure 6

d. Grasp the carriage with both hands (figure 4) and

carefully start the carriage bearings onto the tracks

on the radial arm, Be sure to hold the assembly

parallel to the arm as it is carefully slipped into

position until all four bearings are on the tracks in

order to prevent excessive strain on the bearings

and tracks.

e, Install and tighten the cariage stop screw and

Iockwasher. (See figure 5.)

f. Move the carriage back and forth along the radial

arm. It should roll smoothly throughout the entire

travel range.

Installing Table Supports

a. Install right- and left-hand table supports (figure 6)

with two 3/8-16 x 1-inch, hex-head screws, 13/32

flat washers, 3/8-inch Iockwashers and 3/8-16

square nuts in each table support. Refer to inset in

figure 6 for correct location of nuts and washers.

Tighten these screws just enough to permit the

table supports to slip when tapped with a mallet -

to facilitate later adjustments. Tap each table

support until the screw mounting slots are

positioned with screws approximately equal

distant from ends of slots.

6

Loading ...

Loading ...

Loading ...