Loading ...

Loading ...

Loading ...

4.

a. Crosscutting

(1) Heeling to the right will tend to slide the

workpiece toward the right along the rip

fence, as the cut is being made, and make a

square cut almost impossible.

(2) Heeling to the left will tend to slide the board

to the left along the fence.

b. Miter Cutting - Same as crosscutting, except to a

lesser or greater degree, depending upon the angle.

c. In-Ripping

(1) Heeling to the right will force the workpiece

against the rip fence.

(2) Heeling to the left will force the workpiece

away from the fence.

d. Out-Ripping - The exact reverse of in-ripping.

e. Checking and Adjusting to Eliminate "Heeling".

(1) Loosen the guard clamp knob and tilt the

guard upward at the front to expose the saw

blade, as shown in figure 75.

(2) Place a square against the rip fence and the

saw blade as shown in figure 75. The long leg

of the square must be held firmly against the

rip fence and table top and the short leg must

not touch any of the teeth on the saw blade.

(3) tf the square does not touch the

hollow-ground blade at points shown in figure

75, a heel condition exists (either to the left

or right). To correct the condition, proceed as

follows:

(a) Remove the left-hand carriage cover

(figure 75),

ib) Loosen the yoke clamp handle.

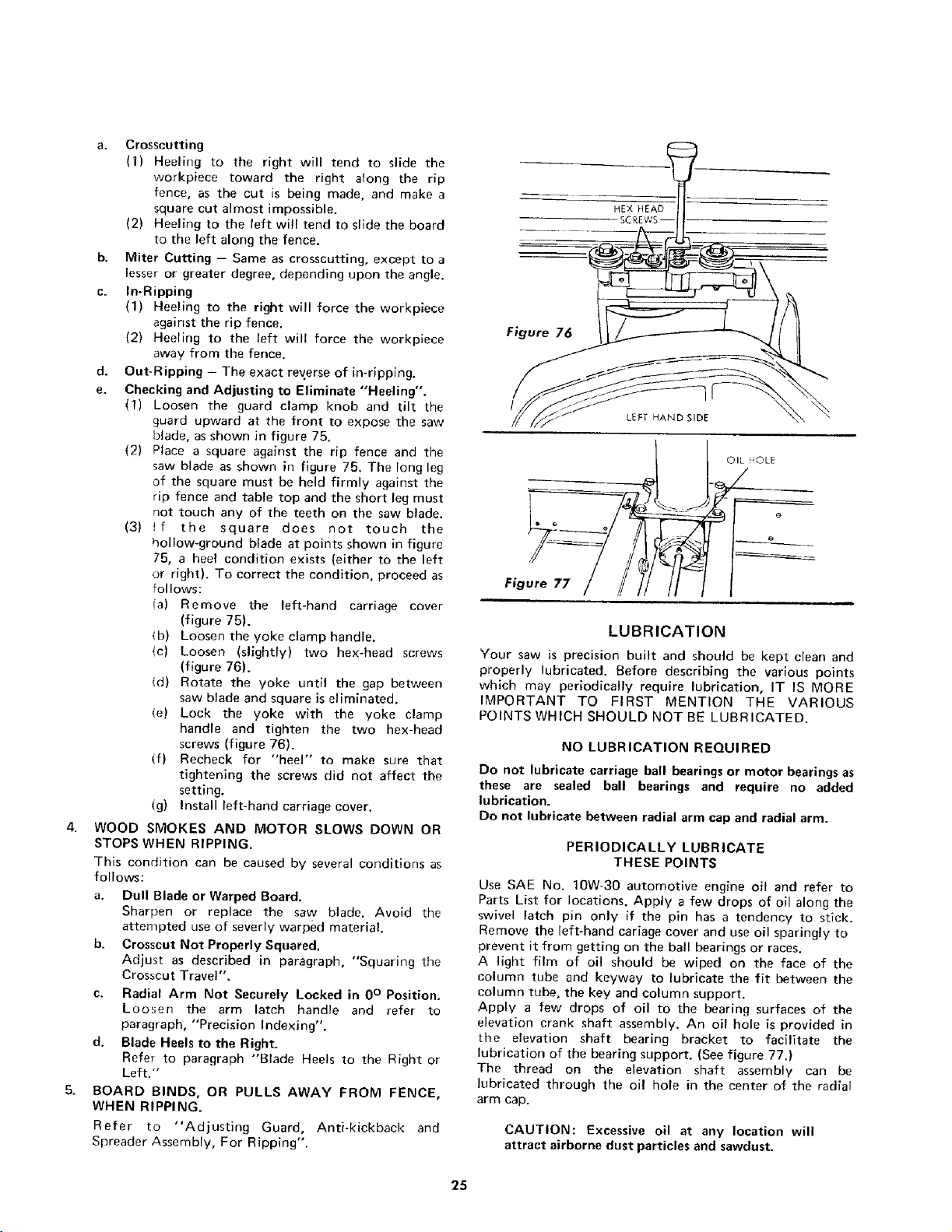

!c) Loosen (slightly) two hex-head screws

(figure 76).

_d) Rotate the yoke until the gap between

saw blade and square is eliminated.

<e) Lock the yoke with the yoke clamp

handle and tighten the two hex-head

screws (figure 76).

(f) Recheck for "heel" to make sure that

tightening the screws did not affect the

setting.

(g) Install left-hand carriage cover.

WOOD SMOKES AND MOTOR SLOWS DOWN OR

STOPS WHEN RIPPING.

This condition can be caused by several conditions as

follows:

a. Dull Blade or Warped Board.

Sharpen or replace the saw blade. Avoid the

attempted use of severly warped material.

b. Crosscut Not Properly Squared.

Adjust as described in paragraph, "Squaring the

Crosscut Travel".

c. Radial Arm Not Securely Locked in 0° Position.

Loosen the arm latch handle and refer to

paragraph, "Precision Indexing".

d. Blade Heels to the Right.

Refer to paragraph "Blade Heels to the Right or

Left."

BOARD BINDS, OR PULLS AWAY FROM FENCE,

WHEN RIPPING.

Refer to "Adjusting Guard, Anti-kickback and

Spreader Assembly, For Ripping".

HEX HEAD

SCREWS--

Figure 76

LEFT HAND SIDE

OIL _OLE

LUBRICATION

Your saw is precision built and should be kept clean and

properly lubricated. Before describing the various points

which may periodically require lubrication, IT IS MORE

IMPORTANT TO FIRST MENTION THE VARIOUS

POINTS WHICH SHOULD NOT BE LUBRICATED.

NO LUBRICATION REQUIRED

Do not lubricate carriage ball bearings or motor bearings as

these are sealed ball bearings and require no added

lubrication.

Do not lubricate between radial arm cap and radial arm.

PERIODICALLY LUBRICATE

THESE POINTS

Use SAE No. 10W-30 automotive engine oil and refer to

Parts List for locations. Apply a few drops of oil along the

swivel latch pin only if the pin has a tendency to stick.

Remove the left-hand cariage cover and use oil sparingly to

prevent it from getting on the ball bearings or races.

A light film of oil should be wiped on the face of the

column tube and keyway to lubricate the fit between the

column tube, the key and column support.

Apply a few drops of oil to the bearing surfaces of the

elevation crank shaft assembly. An oil hole is provided in

[he elevation shaft bearing bracket to facilitate the

lubrication of the bearing support. (See figure 77.)

The thread on the elevation shaft assembly can be

lubricated through the oil hole in the center of the radial

arm cap.

CAUTION: Excessive oil at any location will

attract airborne dust particles and sawdust.

25

Loading ...

Loading ...

Loading ...