Loading ...

Loading ...

Loading ...

SOCKE_{

SEf SCREV,

IFOUR TOIAL)

(2)

BEVEL LOCK KNOB

ECCENTRIC

SCREW

lEVEL iNDEX

SCALE

_,OR

Figure 65

ECCENTRIC

SCREW

Figure 68 Figure 69

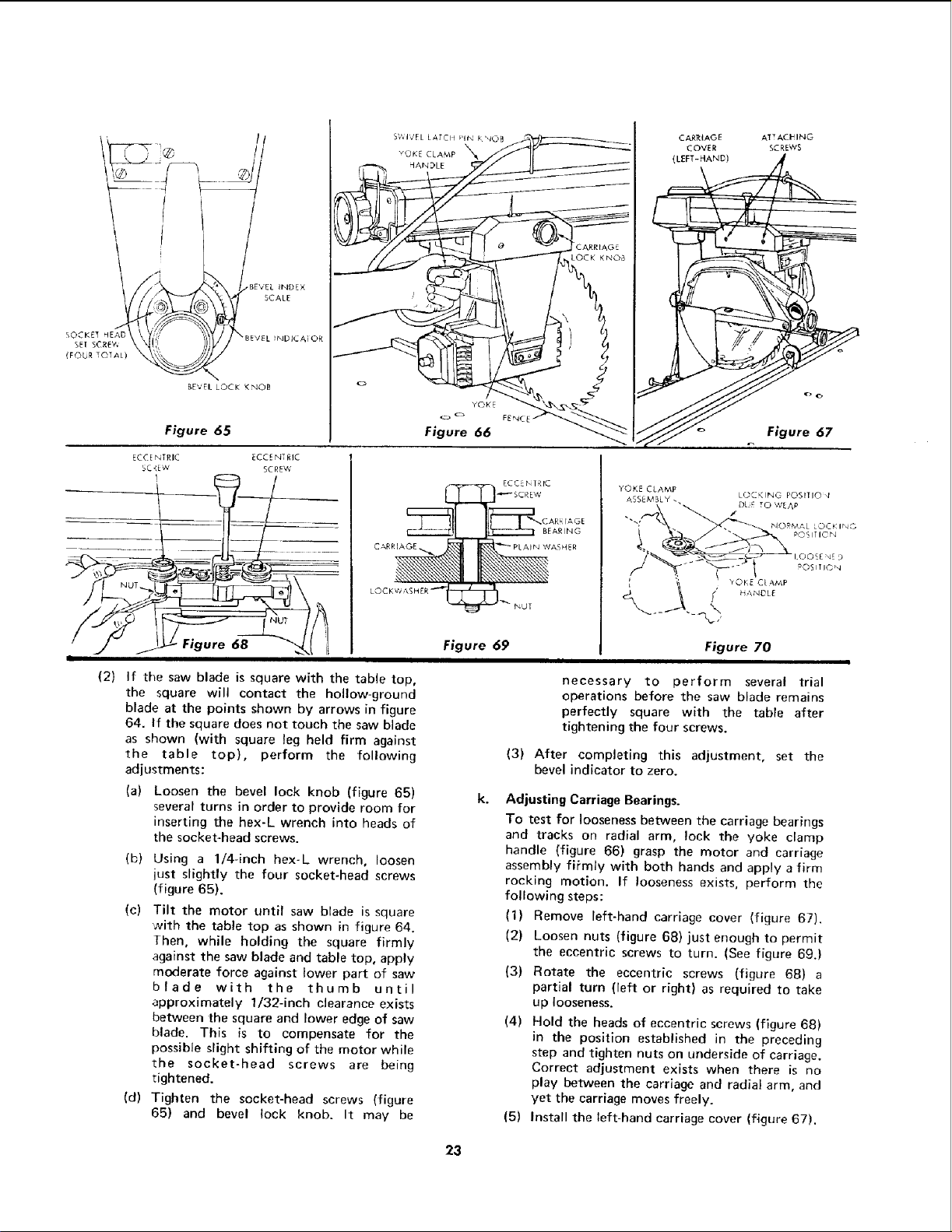

If the saw blade is square with the table top,

the square will contact the hollow-ground

blade at the points shown by arrows in figure

64. If the square does not touch the saw blade

as shown (with square leg held firm against

the table top), perform the following

adjustments:

(a) Loosen the bevel lock knob (figure 65)

several turns in order to provide room for

inserting the hex-L wrench into heads of

the socket-head screws.

(b) Using a 1/4-inch hex-L wrench, loosen

just slightly the four socket-head screws

(figure 65).

(c) Tilt the motor until saw blade is square

with the table top as shown in figure 64.

Then, while holding the square firmly

against the saw blade and table top, apply

moderate force against lower part of saw

blade with the thumb until

approximately 1/32-inch clearance exists

between the square and lower edge of saw

blade. This is to compensate for the

possible slight shifting of the motor while

the socket-head screws are being

tightened.

(d) Tighten the socket-head screws (figure

65) and bevel lock knob. It may be

CARRIAGE

COVER

{LEFT-HAND)

BEARING

YOKE CLAMP

ASSEMBLY.

ATTACHNG

SCREWS

Figure 67

Figure 70

necessary to perform several trial

operations before the saw blade remains

perfectly square with the table after

tightening the four screws.

(3) After completing this adjustment, set the

bevel indicator to zero.

Adjusting Carriage Bearings.

To test for looseness between the carriage bearings

and tracks on radial arm, lock the yoke clamp

handle (figure 66) grasp the motor and carriage

assembly firmly with both hands and apply a firm

rocking motion. If looseness exists, perform the

following steps:

(1) Remove left-hand carriage cover (figure 67).

(2) Loosen nuts (figure 68) just enough to permit

the eccentric screws to turn. (See figure 69.)

(3) Rotate the eccentric screws (figure 68) a

partial turn (left or right) as required to take

up looseness.

(4) Hold the heads of eccentric screws (figure 68)

in the position established in the preceding

step and tighten nuts on underside of carriage.

Correct adjustment exists when there is no

play between the carriage and radial arm, and

yet the carriage moves freely.

(5) Install the left-hand carriage cover (figure 67).

23

Loading ...

Loading ...

Loading ...