Loading ...

Loading ...

Loading ...

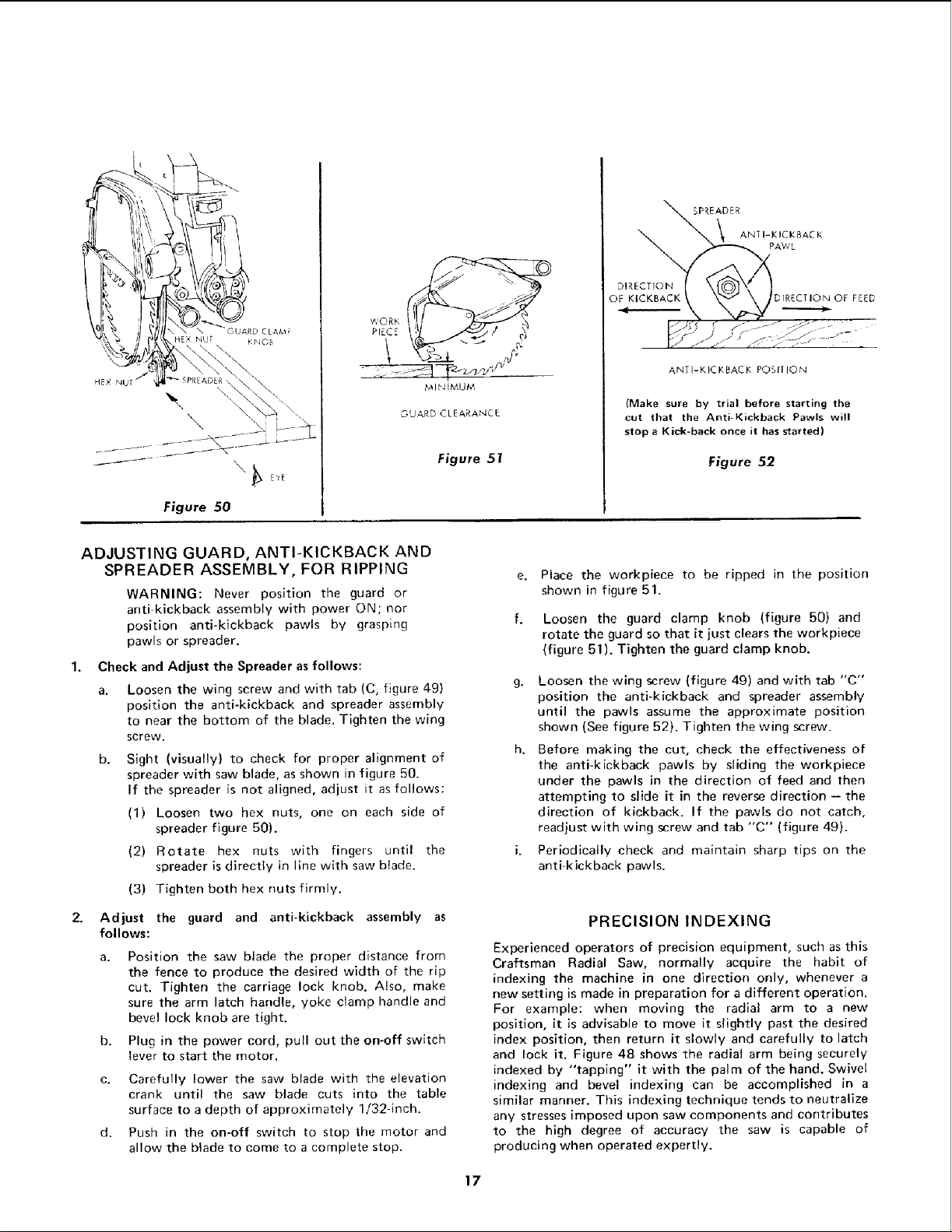

MINIMUM

C-U ARD CLEARANCE

Figure 51

SPREADER

ANTI-KICKBAC K

PAWL

DIRECTION

OF KICKBACK

i

_DIRBCTION OF FEED

22--

ANTI-KICKBACK POSITION

(Make sure by trial before starting the

cut that the Anti-Kickback Pawls will

stop a Kick-back once it has started)

Figure 52

ADJUSTING GUARD, ANTI-KICKBACK AND

SPREADER ASSEMBLY, FOR RIPPING

WARNING: Never position the guard or

anti-kickback assembly with power ON; nor

position anti-kickback pawls by grasping

pawls or spreader.

1.

Check and Adjust the Spreader as follows:

a. Loosen the wing screw and with tab (C, figure 49)

position the anti-kickback and spreader assembly

to near the bottom of the blade. Tighten the wing

screw.

b.

Sight (visually) to check for proper alignment of

spreader with saw blade, as shown in figure 50.

If the spreader is not aligned, adjust it as follows:

(1) Loosen two hex nuts, one on each side of

spreader figure 50).

(2) Rotate hex nuts with fingers until the

spreader is directly in line with saw blade.

(3) Tighten both hex nuts firmly.

Adjust the guard and anti-kickback assembly as

follows:

a. Position the saw blade the proper distance from

the fence to produce the desired width of the rip

cut. Tighten the carriage lock knob. Also, make

sure the arm latch handle, yoke clamp handle and

bevel lock knob are tight.

b. Plug in the power cord, pull out the on-off switch

lever to start the motor.

c. Carefully lower the saw blade with the elevation

crank until the saw blade cuts into the table

surface to a depth of approximately 1!32-inch.

d. Push in the on-off switch to stop the motor and

allow the blade to come to a complete stop.

e.

f.

Place the workpiece to be ripped in the position

shown in figure 51.

Loosen the guard clamp knob (figure 50) and

rotate the guard so that it just clears the workpiece

(figure 51). Tighten the guard clamp knob.

g. Loosen the wing screw (figure 49) and with tab "C"

position the anti-kickback and spreader assembly

until the pawls assume the approximate position

shown (See figure 52). Tighten the wing screw.

h. Before making the cut, check the effectiveness of

the anti-kickback pawls by sliding the workpiece

under the pawls in the direction of feed and then

attempting to slide it in the reverse direction - the

direction of kickback. If the pawls do not catch,

readjust with wing screw and tab "'C" (figure 49).

i. Periodically check and maintain sharp tips on the

anti-kickback pawls.

PRECISION INDEXING

Experienced operators of precision equipment, such as this

Craftsman Radial Saw, normally acquire the habit of

indexing the machine in one direction only, whenever a

new setting is made in preparation for a different operation.

For example: when moving the radial arm to a new

position, it is advisable to move it slightly past the desired

index position, then return it slowly and carefully to latch

and lock it. Figure 48 shows the radial arm being securely

indexed by "tapping" it with the palm of the hand. Swivel

indexing and bevel indexing can be accomplished in a

similar manner. This indexing technique tends to neutralize

any stresses imposed upon saw components and contributes

to the high degree of accuracy the saw is capable of

producing when operated expertly.

17

Loading ...

Loading ...

Loading ...