Loading ...

Loading ...

Loading ...

basic saw operations

BASIC SAW OPERATIONS

Yok_r Craftsma_ 12inch Radial Saw is an extremely

versatile tool, capable of performing innumerable cuts with

sufficient accuracy to satisfy both amateur and professional

wood-working requirements, Basic saw operations are

summarized into six categories, explained and illustrated in

the following paragraphs. A manual entitled "The Radial

Saw'" is available at your nearest Sears Retail Store or

Catalog Order House. This manual contains considerable

data and project ideas applicable to the radial saw.

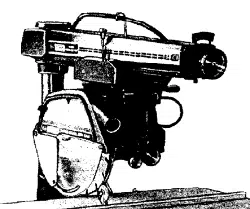

NOTE: Refer to paragraphs under

"OPERATION" for illustrations and

descriptions of controls.

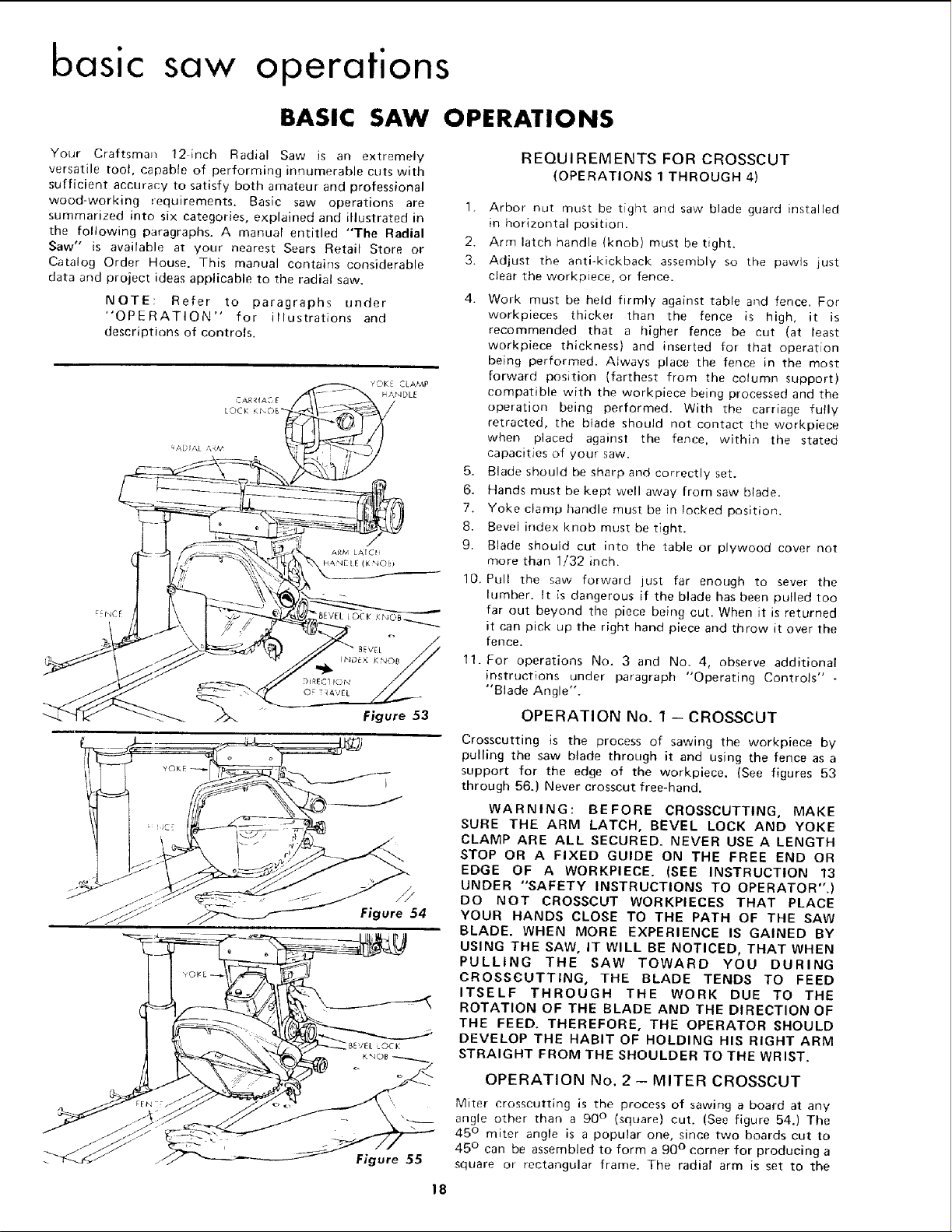

BEVEL LOCK

Figure 55

REQUIREMENTS FOR CROSSCUT

(OPERATIONS 1 THROUGH 4)

1. ArboP nut must be tight and saw blade guard installed

in horizontal position.

2. Arm latch handle (knob) must be tight.

3. Adjust the anti-kickback assembly so the pawls just

clear the workpiece, or fence.

4. Work must be held firmly against table end fence. For

workpieces thicker than the fence is high, it is

recommended that a higher fence be cut (at least

workpiece thickness) and inserted for that operation

being performed. Always place the fence in the most

forward position (farthest from the column support)

compatible with the workpiece being processed and the

operation being performed. With the carriage fully

retracted, the blade should not contact the workpiece

when placed against the fence, within the stated

capacities of your saw.

5. Blade should be sharp and correctly set.

6. Hands must be kept well away from saw blade.

7. Yoke clamp handle must be in locked position.

8. Bevel index knob must be tight.

9. Blade should cut into the table or plywood cover not

more than 1/32 inch.

10. Pull the saw forward just far enough to sever the

lumber, tt is dangerous if the blade has been pulled too

far out beyond the piece being cut. When it is returned

it can pick up the right hand piece and throw it over the

fence°

11. For operations No. 3 and No. 4, observe additional

instructions under paragraph "Operating Controls" -

"Blade Angle".

OPERATION No. 1 - CROSSCUT

Crosscutting is the process of sawing the workpiece by

pulling the saw blade through it and using the fence as a

support for the edge of the workpiece. (See figures 53

through 56.) Never crosscut free-hand.

WARNING: BEFORE CROSSCUTTING, MAKE

SURE THE ARM LATCH, BEVEL LOCK AND YOKE

CLAMP ARE ALL SECURED. NEVER USE A LENGTH

STOP OR A FIXED GUIDE ON THE FREE END OR

EDGE OF A WORKPIECE. (SEE INSTRUCTION 13

UNDER "SAFETY INSTRUCTIONS TO OPERATOR".)

DO NOT CROSSCUT WORKPIECES THAT PLACE

YOUR HANDS CLOSE TO THE PATH OF THE SAW

BLADE. WHEN MORE EXPERIENCE IS GAINED BY

USING THE SAW, IT WILL BE NOTICED, THAT WHEN

PULLING THE SAW TOWARD YOU DURING

CROSSCUTTING, THE BLADE TENDS TO FEED

ITSELF THROUGH THE WORK DUE TO THE

ROTATION OF THE BLADE AND THE DIRECTION OF

THE FEED. THEREFORE, THE OPERATOR SHOULD

DEVELOP THE HABIT OF HOLDING HIS RIGHT ARM

STRAIGHT FROM THE SHOULDER TO THE WRIST.

OPERATION No. 2 - MITER CROSSCUT

Miter crosscutting is the process of sawing a board at any

angle other than a 90 ° (square) cut. (See figure 54.) The

45 ° miter angle is a popular one, since two boards cut to

45 ° can be assembled to form a 90 ° corner for producing a

square or rectangular frame. The radial arm is set to the

18

Loading ...

Loading ...

Loading ...