Loading ...

Loading ...

Loading ...

desired angle of cut; yoke and bevel settings indexed at 0°

(and locked) as in square crosscutting. The board being cut

is hetd firmly against the fence and the carriage pulled

forward along the radial arm to perform the desired cut. As

in "Operation No. 1", the carriage should be r-eturned to

full rear position and the saw blade allowed to come to a

comolete stoo before removinQ the boards from saw t_ble.

OPERATION No. 3 - BEVEL CROSSCUT

Bevel crosscutting is the process of sawing at g0 ° (square)

across the board with the saw blade set at an angle other

than g0 ° to the saw table. (See figure 55.) The radial arm

and yoke are indexed at 0° and locked, but the bevel is set

to the desired angle of cut. The board is held firmly against

the fence and the carriage pulled forward along the radial

arm to produce the cut. The carriage should be returned to

full rearward position and the saw blade allowed co come to

a complete stop before removing the boards from saw table.

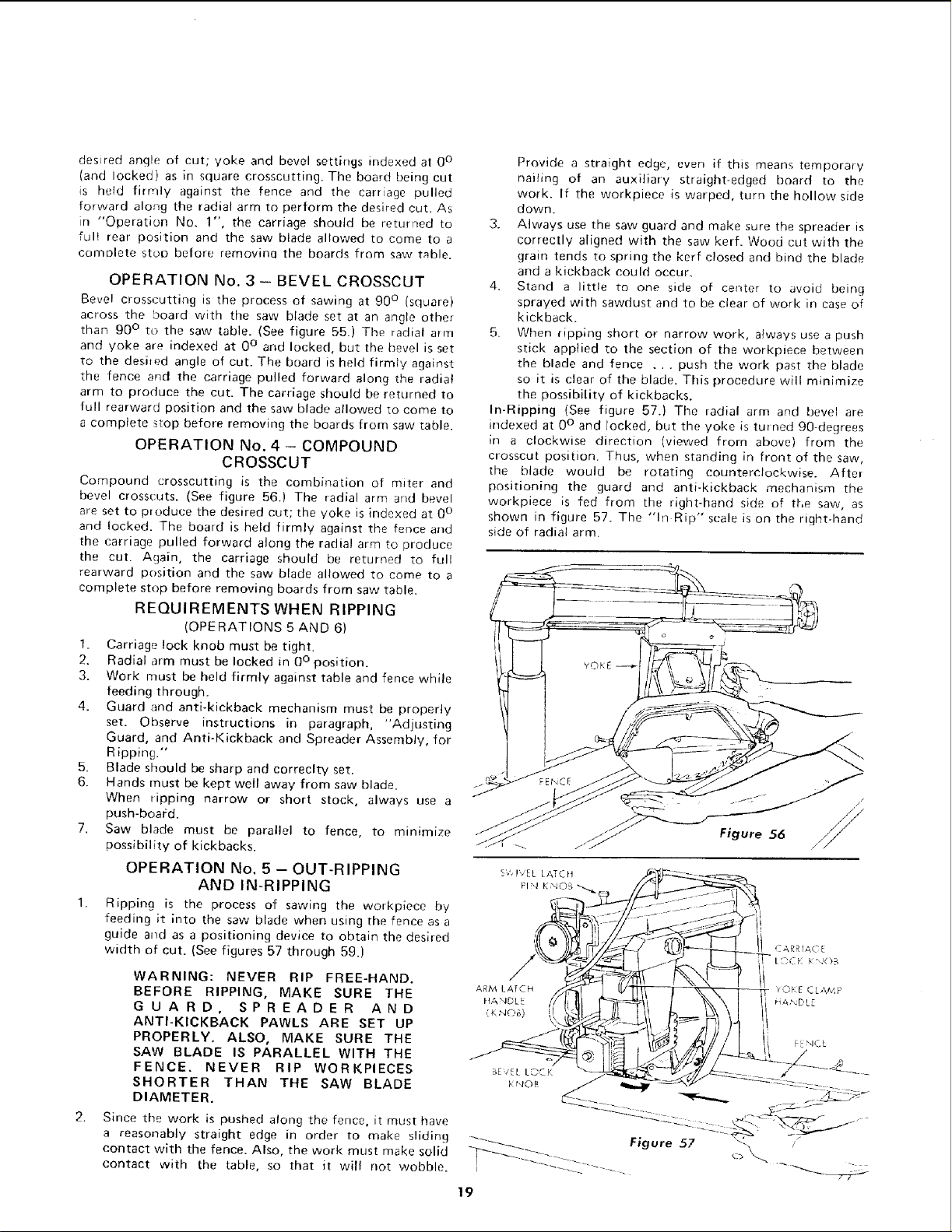

OPERATION No. 4 - COMPOUND

CROSSCUT

Compound crosscutting is the combination of miter and

bevel crosscuts. (See figure 56.) The radial arm arrd bevel

are set to produce the desired cut; the yoke is indexed at O°

and locked. The board is held firmly against the fence and

the carriage pulled forward along the radial arm to produce

the cut. Again, the carriage should be returned to full

rearward position and the saw blade allowed to come to a

complete stop before removing boards from saw table.

REQUIREMENTS WHEN RIPPING

(OPERATIONS 5 AND 6)

1. Carriage lock knob must be tight.

2. Radial arm must be locked in 0° position.

3. Work must be held firmly against table and fence while

feeding through.

4. Guard and anti-kickback mechanism must be properly

set. Observe instructions in paragraph, "Adjusting

Guard, and Anti-Kickback and Spreader Assembly, for

Ripping."

5. Blade should be sharp and correclty set.

6. Hands must be kept well away from saw blade.

When ripping narrow or short stock, always use a

push-board.

7. Saw blade must be parallel to fence, to minimize

possibility of kickbacks.

OPERATION No. 5 -- OUT-RIPPING

AND IN-RIPPING

1. Ripping is the process of sawing the workpiece by

feeding ;t into the saw blade when using the fence as a

guide and as a positioning device to obtain the desired

width of cut. (See figures 57 through 5g.)

2.

Provide a straight edge, even if this means temporary

nailing of an auxiliary straight-edged board to the

work. If the workpiece is warped, turn the hollow side

down.

3. Always use the saw guard and make sure the spreader is

correctly aligned with the saw kerf. Wood cut with the

grain tends to spring the kerf closed and bind the blade

and a kickback could occur.

4. Stand a little to one side of center to avoid being

sprayed with sawdust and to be clear of work in case of

kickback.

5. When ripping short or narrow work, always use a push

stick applied to the section of the workpiece between

the blade and fence ... push the work past the blade

so it is clear of the blade. This procedure will minimize

the possibility of kickbacks.

In-Ripping (See figure 57.) Time radial arm and bevel are

indexed at 0° and locked, but the yoke is twned 90-degrees

in a clockwise direction (viewed from above) from the

crosscut position. Thus, when standing in front of the saw,

the blade would be rotating counterclockwise. After

positioning the guard and anti-kickback mechanism the

workpiece is fed from the right-hand side of the saw, as

shown in figure 57. The "in Rip" scale is on the right-hand

side of radial arm.

WARNING: NEVER RIP FREE-HAND.

BEFORE RIPPING, MAKE SURE THE Am_L,_rCH

HANDLE

G U A R D, SPREADER AND _',K_Jo_)

ANTI-KICKBACK PAWLS ARE SET UP

PROPERLY. ALSO, MAKE SURE THE

SAW BLADE IS PARALLEL WITH THE

FENCE. NEVER RIP WORKPIECES BE/ELLOCK

SHORTER THAN THE SAW BLADE _r,_o_

DIAMETER.

Since the work is pushed along the fence, it must have

a reasonably straight edge in order to make sliding

contact with the fence. Also, the work must make solid

contact with the table, so that it will not wobble.

OKE CLAMP

HANDL

_-_ Figure 57

19

Loading ...

Loading ...

Loading ...