Loading ...

Loading ...

Loading ...

operating controls

3.

ARtd_ LATCH HANDLL

Figure 48

(2)

ZAB A

W'NG

TAB C SCREV_ TAB S

LOWER OUTER LOWER NNER

GUARD GUARD

OUTSIDE iNS1lie

VIEW VIEW

Figure 49

i

pull out the arm latch lever (1) and move the

radial arm off the index position. Release the

arm latch lever (I).

(3)

Move the radial arm into the desired index

position (do not bump or jar it) and push on

the arm latch lever (1, figure 46) solidly with

the palm of the hand. (See figure 48). This is

very important as it insures proper seating of

the arm lock pin in the arm latch, thus always

returning the arm to the correct position.

Lock the radial arm by rotating the arm latch

handle (17, figure 46) clockwise until tight.

"Yoke Pivot"

a. Two controls are used in this operation. They are:

swivel latch pin knob (2, figure 46) and yoke

clamp handle (7, figure 46).

b. The swivel latch pin automatically indexes the

yoke at each 90 ° position. Lift the spring-loaded

knob to release it.

C.

The yoke clamp handle (7, figure 46) locks the

yoke to the carriage in any position. Pull the

handle forward to release the yoke; push the

handle rearward to secure the yoke.

4. "Carriage Lock"

5_

a. The carriage lock knob (6, figure 46) is rotated

clockwise to secure the carriage on the radial arm,

and counterclockwise to release it.

b.

When performing a square crosscut or angle cut,

the carriage lock knob must be rotated

counterclockwise until the carriage is free to travel

along the arm. This knob should be tightened

except when the operator is ready to grasp the

bevel index handle (14, figure 46) and make a cut.

"Blade Angle"

a. The two controls used in angular positioning and

indexing of the motor to provide the desired saw

8.

16

b.

d.

blade angle are: bevel lock knob (12, figure 46)

and latch pin handle (15, figure 46.)

The bevel index scale (11, figure 46) indicates the

angular position of the motor with respect to

horizontal from 0° to 90 ° in either vertical

position.

The latch pin handle (15, figure 46)automatically

indexes the motor at 0°, 45 ° and 90 ° up and

down. Lift the latch pin handle to release it. At

any other position, the latch pin handle does not

engage.

The bevel lock knob (12, figure 46) locks the

motor to the yoke when the motor is in any

position. Rotate it clockwise to lock;

counterclockwise to unlock.

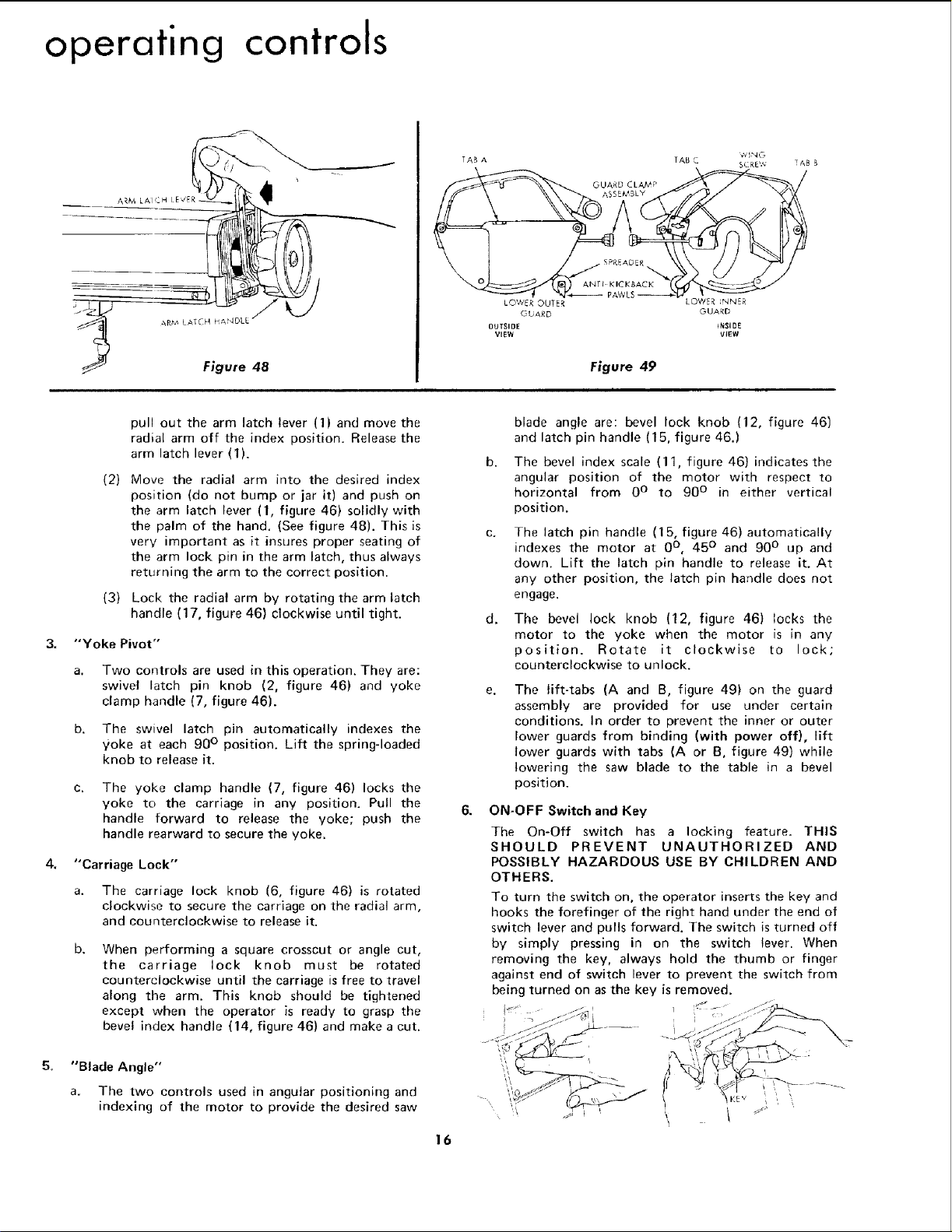

The lift-tabs (A and B, figure 49) on the guard

assembly are provided for use under certain

conditions. In order to prevent the inner or outer

lower guards from binding (with power off}, lift

lower guards with tabs (A or B, figure 49) while

lowering the saw blade to the table in a bevel

position.

ON-OFF Switch and Key

The On-Off switch has a locking feature. THIS

SHOULD PREVENT UNAUTHORIZED AND

POSSIBLY HAZARDOUS USE BY CHILDREN AND

OTHERS.

To turn the switch on, the operator inserts the key and

hooks the forefinger of the right hand under the end of

switch lever and pulls forward. The switch is turned off

by simply pressing in on the switch lever. When

removing the key, always hold the thumb or finger

against end of switch lever to prevent the switch from

being turned on as the key is removed.

i

I

t! ,

Loading ...

Loading ...

Loading ...