Loading ...

Loading ...

Loading ...

electrical connections

WARNING: DO NOT PERMIT FINGERS

TO CONTACT THE TERMINALS OF

POWER OR MOTOR PLUGS WHEN

INSTALLING OR REMOVING THE PLUG

TO OR FROM A LIVE POWER SOURCE.

(SEE FIGURE 43.)

/

GROUNDEL;

OU[LE T B©X

Figure 43

NO ADAPTER IS AVAILABLE FOR THIS TYPE PLUG.

CAP - FLAG TERMINAL

_OWER BLACK BLACK

CORDI Z _ _

w WHITE WHITE

0 CORD

":- SWITCH

GROUND

SCREW

Figure 44

This tool should be grounded while in use to protect _he

operator from electrical shock.

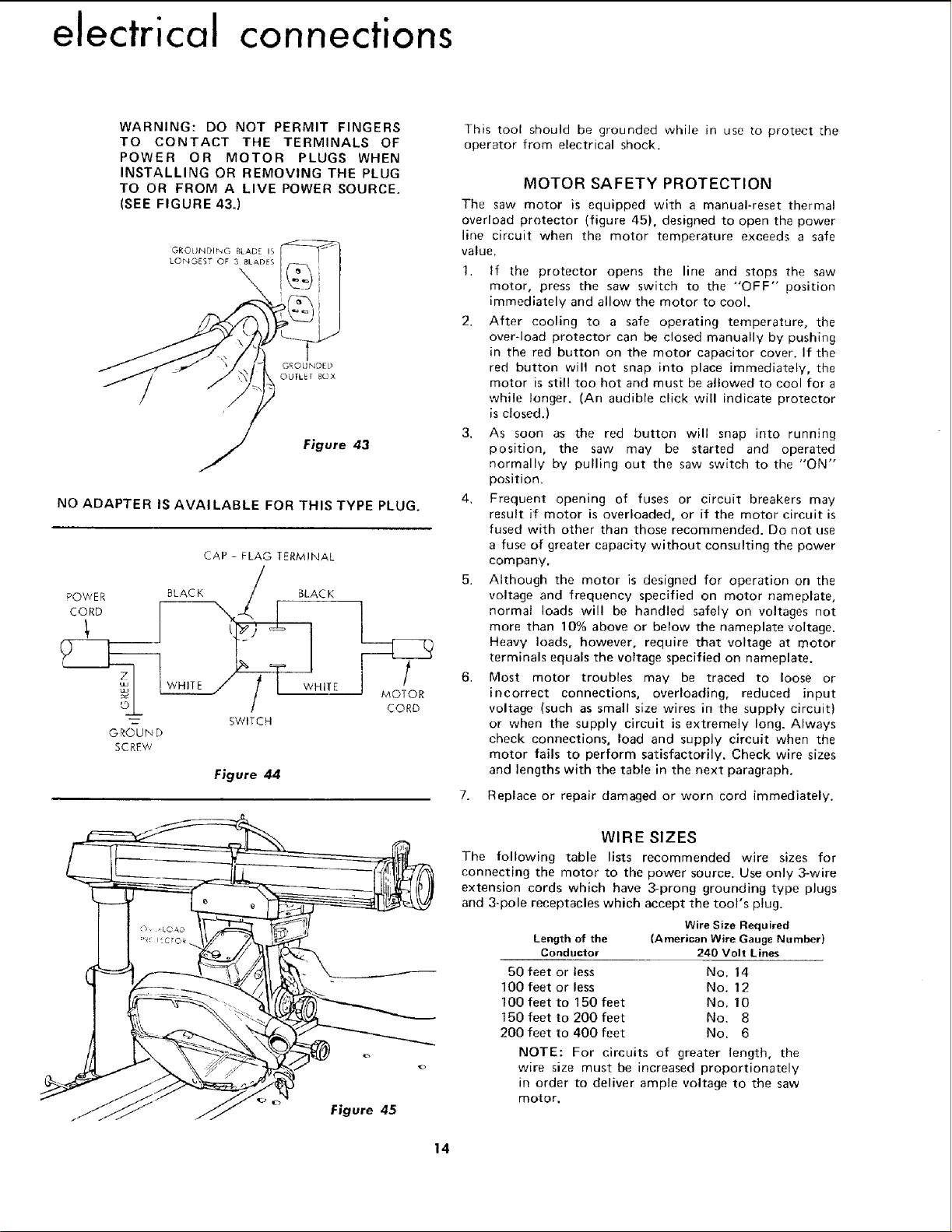

MOTOR SAFETY PROTECTION

The saw motor is equipped with a manual-reset thermal

overload protector (figure 45). designed to open the power

line circuit when the motor temperature exceeds a safe

value.

1. If the protector opens the line and stops the saw

motor, press the saw switch to the "'OFF" position

immediately and allow the nqotor to cool.

2. After cooling to a safe operating temperature, the

over-load protector can be closed manually by pushing

in the red button on the motor capacitor cover. If the

red button will not snap into place immediately, the

motor is still too hot and must be allowed to cool for a

while longer. (An audible click will indicate protector

is closed.)

3. As soon as the red button will snap into running

position, the saw may be started and operated

normally by pulling out the saw switch to the "ON"

position.

4. Frequent opening of fuses or circuit breakers may

result if motor is overloaded, or if the motor circuit is

fused with other than those recommended. Do not use

a fuse of greater capacity without consulting the power

company.

5. Although the motor is designed for operation on the

voltage and frequency specified on motor nameplate,

normal loads will be handled safely on voltages not

more than 10% above or below the nameplate voltage.

Heavy loads, however, require that voltage at motor

terminals equals the voltage specified on nameplate.

6. Most motor troubles may be traced to loose or

incorrect connections, overloading, reduced input

voltage (such as small size wires in the supply circuit)

or when the supply circuit is extremely long. Always

check connections, load and supply circuit when the

motor fails to perform satisfactorily. Check wire sizes

and lengths with the table in the next paragraph.

7. Replace or repair damaged or worn cord immediately.

Figure 45

WIRE SIZES

The following table lists recommended wire sizes for

connecting the motor to the power source. Use only 3-wire

extension cords which have 3-prong grounding type plugs

and 3-pole receptacles which accept the tool's plug.

Wire Size Required

Length of the (American Wire Gauge Number)

Conductor 240 Volt Lines

50 feet or less No. 14

100 feet or less No. 12

100 feet to 150 feet No. 10

150feet to 200feet No. 8

200 feet to 400 feet No. 6

NOTE: For circuits of greater length, the

wire size must be increased proportionately

in order to deliver ample voltage to the saw

motor.

14

Loading ...

Loading ...

Loading ...