Loading ...

Loading ...

Loading ...

trouble shooting

TROUBL ESHOOTING

Even though the finest materials and precision

workmanship have been incorporated into your Craftsman

saw, it is reasonable to expect some wear after long periods

of use. Adjustment facilities have been built into the saw to

compensate for this wear. Looseness due to wear, rough

handling, or improper adjustments will usually be indicated

by reduced accuracy or the inability of the saw to perform

as intended. The usual operating "troubles" are listed in the

following paragraphs with the necessary corrections

described and illustrated.

1. LOOSENESS OF COLUMN TUBE IN COLUMN

SUPPORT -- ELEVATION CRANK OPERATES

ROUGHLY, OR CHATTERS WHEN ROTATED.

When this condition exists, square crosscuts are likely

to be difficult to make and repeated cuts inaccurate.

Adjust the column tube key as follows:

a. Checking for Looseness of Column Tube in

Column Support.

(1) Tighten arm latch handle.

(2) Grasp the arm latch handle with one hand and

hold fingers of other hand at parting line

between column tube and column support.

(See figure 60.)

(3) Apply gentle side force to the radial arm in

opposing directions. Any looseness between

column and column support (indicated by

arrow in figure 60) can be felt with fingers.

(4) If looseness can be felt, perform the following

operations:

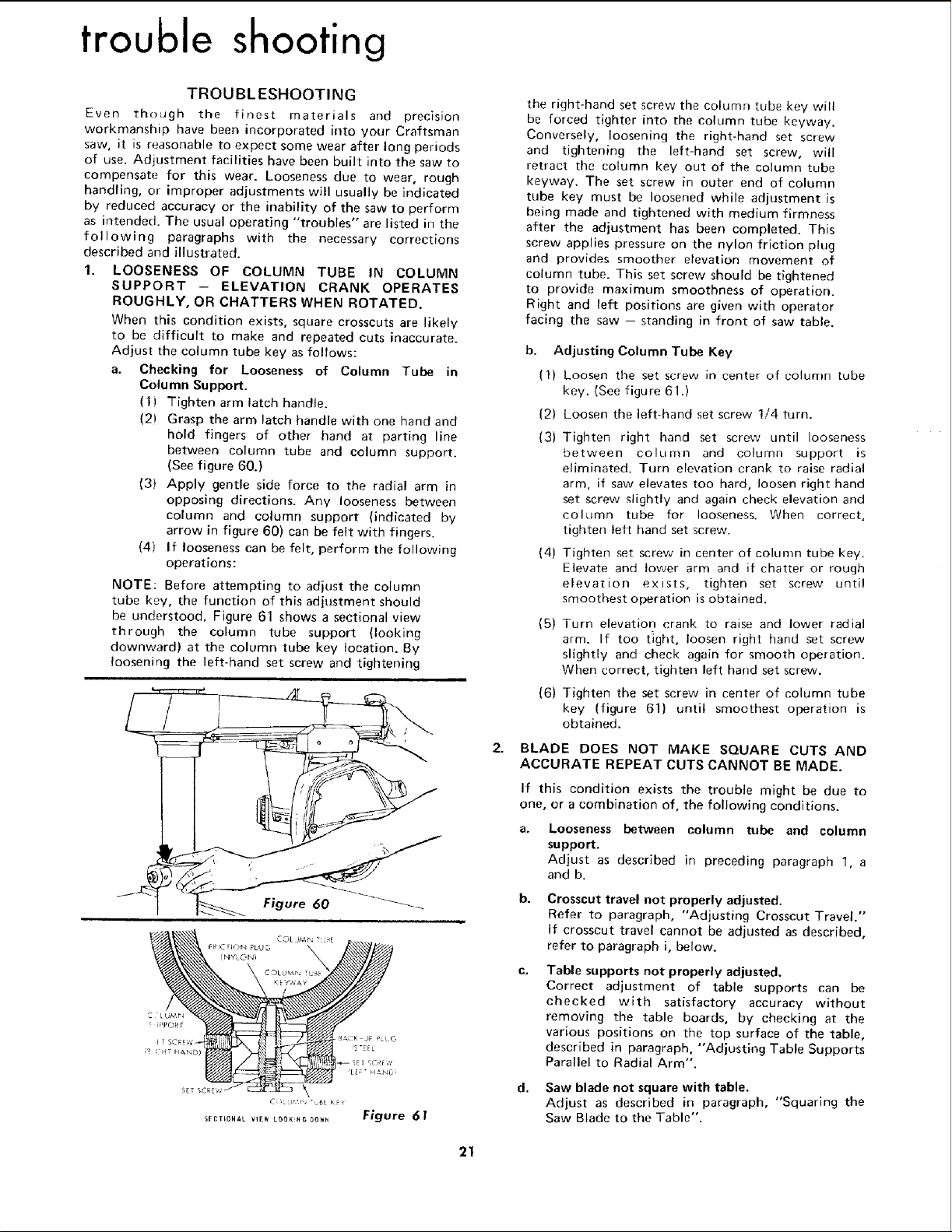

NOTE: Before attempting to adjust the column

tube key, the function of this adjustment should

be understood. Figure 61 shows a sectional view

through the column tube support (looking

downward) at the column tube key location. By

loosening the left-hand set screw and tightening

2.

the right-hand set screw the column tube key will

be forced tighter into the column tube keyway.

Conversely, loosening the right-hand set screw

and tightening the left-hand set screw, will

retract the column key out of the column tube

keyway. The set screw in outer end of column

tube key must be loosened while adjustment is

being made and tightened with medium firmness

after the adjustment has been completed. This

screw applies pressure on the nylon friction plug

and provides smoother elevation movement of

column tube. This set screw should be tightened

to provide maximum smoothness of operation.

Right and left positions are given with operator

facing the saw - standing in front of saw table.

b. Adjusting Column Tube Key

(1) Loosen the set screw in center of column tube

key. (See figure 61.)

[2) Loosen the left-hand set screw 1/4 turn.

(3) Tighten right hand set screw until looseness

between column and column support is

eliminated. Turn elevation crank to raise radial

arm, if saw elevates too hard, loosen right hand

_t screw slightly and again check elevation and

column tube for looseness. When correct,

tighten left hand set screw.

(4) Tighten set screw in center of column tube key.

E}evate and lower arm and if chatter or rough

elevation exists, tighten set screw until

srnootbest operation is obtained.

(5) Turn elevation crank to raise and lower radial

arm. If too tight, loosen right hand set screw

slightly and check again for smooth operation.

When correct, tighten left hand set screw.

{6) Tighten the set screw in center of column tube

key (figure 61) until smoothest operation is

obtained.

BLADE DOES NOT MAKE SQUARE CUTS AND

ACCURATE REPEAT CUTS CANNOT BE MADE.

If this condition exists the trouble might be due to

one, or a combination of, the following conditions.

a. Looseness between column tube and column

support.

Adjust as described in preceding paragraph 1, a

and b.

b°

C.

d,

Crosscut travel not properly adjusted.

Refer to paragraph, "Adjusting Crosscut Travel."

If crosscut travel cannot be adjusted as described,

refer to paragraph i, below.

Table supports not properly adjusted.

Correct adjustment of table supports can be

checked with satisfactory accuracy without

removing the table boards, by checking at the

various positions on the top surface of the table,

described in paragraph, "Adjusting Table Supports

Parallel to Radial Arm".

Saw blade not square with table.

Adjust as described in paragraph, "Squaring the

Saw Blade to the Table".

21

Loading ...

Loading ...

Loading ...