Loading ...

Loading ...

Loading ...

5. Adjustment is complete when both locking and

indexing functions are working properly. Replace

motor support cover.

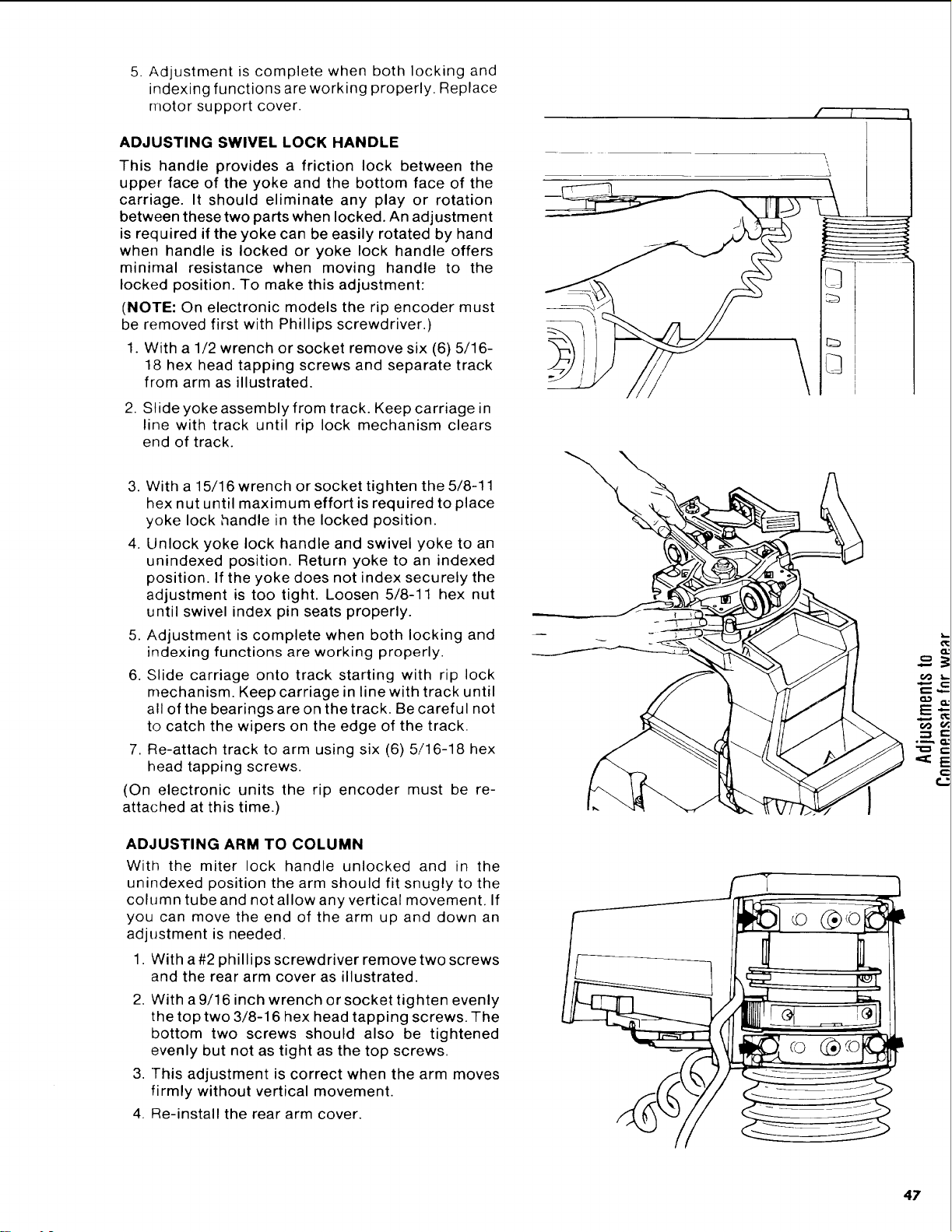

ADJUSTING SWIVEL LOCK HANDLE

This handle provides a friction lock between the

upper face of the yoke and the bottom face of the

carriage. It should eliminate any play or rotation

between these two parts when locked. An adjustment

is required if the yoke can be easily rotated by hand

when handle is locked or yoke lock handle offers

minimal resistance when moving handle to the

locked position. To make this adjustment:

(NOTE: On electronic models the rip encoder must

be removed first with Phillips screwdriver.)

1. With a 1/2 wrench or socket remove six (6) 5/16-

18 hex head tapping screws and separate track

from arm as illustrated.

2. Slide yoke assembly from track. Keep carriage in

line with track until rip lock mechanism clears

end of track.

3. With a 15/16 wrench or socket tighten the 5/8-1 1

hex nut until maximum effort is required to place

yoke lock handle in the locked position.

4. Unlock yoke lock handle and swivel yoke to an

unindexed position. Return yoke to an indexed

position. If the yoke does not index securely the

adjustment is too tight. Loosen 5/8-11 hex nut

until swivel index pin seats properly.

5. Adjustment is complete when both locking and

indexing functions are working properly.

6. Slide carriage onto track starting with rip lock

mechanism. Keep carriage in line with track until

all of the bearings are on the track. Be careful not

to catch the wipers on the edge of the track.

7. Re-attach track to arm using six (6) 5/16-18 hex

head tapping screws.

(On electronic units the rip encoder must be re-

attached at this time.)

ADJUSTING ARM TO COLUMN

With the miter lock handle unlocked and in the

unindexed position the arm should fit snugly to the

column tube and not allow any vertical movement. If

you can move the end of the arm up and down an

adjustment is needed.

1. With a#2 phillips screwdriver remove two screws

and the rear arm cover as illustrated.

2. With a 9/16 inch wrench or socket tighten evenly

the top two 3/8-16 hex head tapping screws. The

bottom two screws should also be tightened

evenly but not as tight as the top screws.

3. This adjustment is correct when the arm moves

firmly without vertical movement.

4. Re-install the rear arm cover.

\

©

#,

6@ t_,

.=_._

47

Loading ...

Loading ...

Loading ...