Loading ...

Loading ...

Loading ...

Adjusting front table lock handles

WARNING: TO AVOID SUDDEN SLIPPAGE,

BREAKAGE, OR THROWING OF PARTS, FRONT

TABLE BOARD LOCK HANDLE MUST LOCK

TABLE BOARDS AND RIP FENCE SECURELY IN

PLACE.

1. To adjust the table board clamps check by

pulling up on rip fence. There should be enough

pressure to keep the rip fence from pulling up. To

adjust the pressure on the clamp:

a. Lift front table lock handles up to release

pressure on boards.

b. Loosen the two eccentric spacer clamps

located at the rear of the table top with a

7/16" wrench or socket.

c. Rotate the spacer toward the rear table board.

Tighten spacer with 7/16" wrench or socket.

Repeat procedure for clamp on other side.

d. Push down on front lock handles and recheck

pressure by pulling up on rip fence. If rip fence

is too loose, repeat adjustment.

/

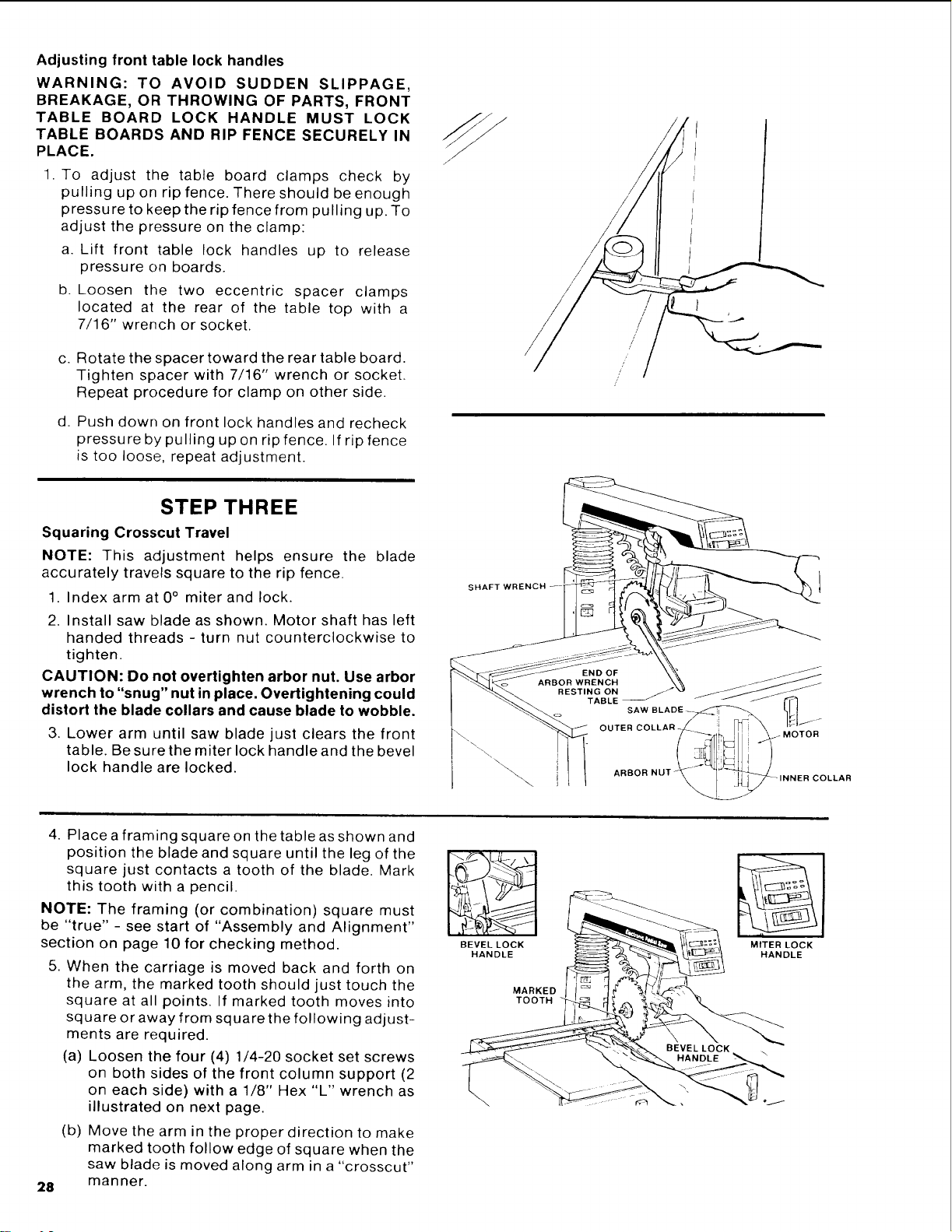

STEP THREE

Squaring Crosscut Travel

NOTE: This adjustment helps ensure the blade

accurately travels square to the rip fence.

1. Index arm at 0° miter and lock.

2. Install saw blade as shown. Motor shaft has left

handed threads - turn nut counterclockwise to

tighten.

CAUTION: Do not overtighten arbor nut. Use arbor

wrench to "snug" nut in place. Overtightening could

distort the blade collars and cause blade to wobble.

3. Lower arm until saw blade just clears the front

table. Be sure the miter lock handle and the bevel

lock handle are locked.

SHAFT

\

4. Placea framing square on the table as shown and

position the blade and square until the leg of the

square just contacts a tooth of the blade. Mark

this tooth with a pencil.

NOTE: The framing (or combination) square must

be "true" - see start of "Assembly and Alignment"

section on page 10 for checking method.

5. When the carriage is moved back and forth on

the arm, the marked tooth should just touch the

square at all points. If marked tooth moves into

square or away from square the following adjust-

ments are required.

(a) Loosen the four (4) 1/4-20 socket set screws

on both sides of the front column support (2

on each side) with a 1/8" Hex "L" wrench as

illustrated on next page.

28

(b) Move the arm in the proper direction to make

marked tooth follow edge of square when the

saw blade is moved along arm in a "crosscut"

manner.

BEVEL LOCK

HANDLE

MARKED

TOOTH

MITER LOCK

HANDLE

Loading ...

Loading ...

Loading ...