Loading ...

Loading ...

Loading ...

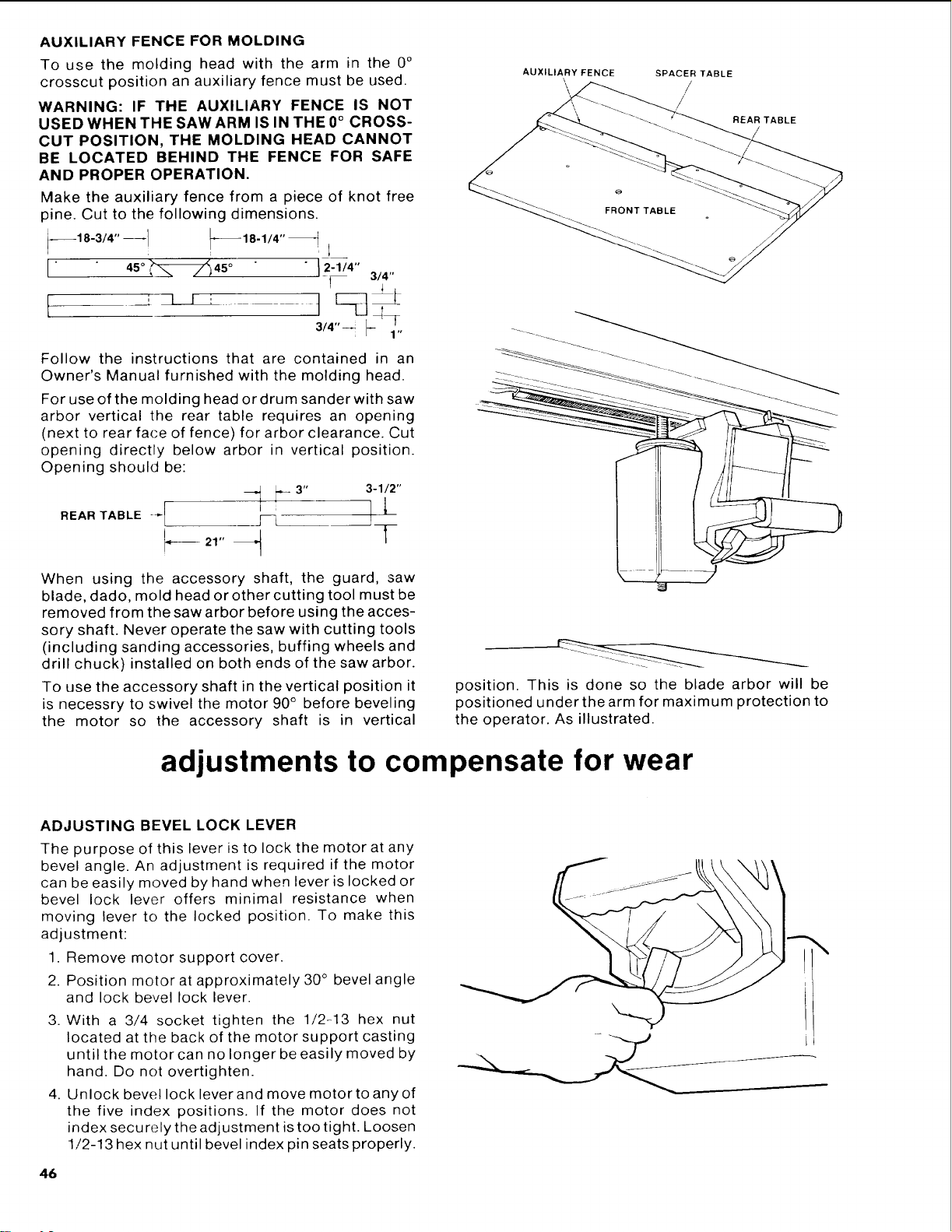

AUXILIARYFENCEFORMOLDING

To use the molding head with the arm in the 0 °

crosscut position an auxiliary fence must be used.

WARNING: IF THE AUXILIARY FENCE IS NOT

USED WHEN THE SAWARM ISIN THE0 ° CROSS-

CUT POSITION, THE MOLDING HEAD CANNOT

BE LOCATED BEHIND THE FENCE FOR SAFE

AND PROPER OPERATION.

Make the auxiliary fence from a piece of knot free

pine. Cut to the following dimensions.

--18-3/4" --1 _'_18"1/4" _i i

3/4"

Follow the instructions that are contained in an

Owner's Manual furnished with the molding head.

For use of the molding head or drum sander with saw

arbor vertical the rear table requires an opening

(next to rear face of fence) for arbor clearance. Cut

opening directly below arbor in vertical position.

Opening should be:

H F

When using the accessory shaft, the guard, saw

blade, dado, mold head or other cutting tool must be

removed from the saw arbor before using the acces-

sory shaft. Never operate the saw with cutting tools

(including sanding accessories, buffing wheels and

drill chuck) installed on both ends of the saw arbor.

To use the accessory shaft in the vertical position it

is necessry to swivel the motor 90 ° before beveling

the motor so the accessory shaft is in vertical

AUXILIARY FENCE

SPACER TABLE

//

REAR TABLE

\ , i

position. This is done so the blade arbor will be

positioned under the arm for maximum protection to

the operator. As illustrated.

adjustments to compensate for wear

ADJUSTING BEVEL LOCK LEVER

The purpose of this lever is to lock the motor at any

bevel angle. An adjustment is required if the motor

can be easily moved by hand when lever is locked or

bevel lock lever offers minimal resistance when

moving lever to the locked position. To make this

adjustment:

1. Remove motor support cover.

2. Position motor at approximately 30 ° bevel angle

and lock bevel lock lever.

3. With a 3/4 socket tighten the 1/2-13 hex nut

located at the back of the motor support casting

untilthe motor can no longer be easily moved by

hand. Do not overtighten.

4. Unlock bevel lock leverand move motor to any of

the five index positions. If the motor does not

index secu rely the adjustment is too tight. Loosen

1/2-13 hex nut until bevel index pin seats properly.

46

Loading ...

Loading ...

Loading ...