Loading ...

Loading ...

Loading ...

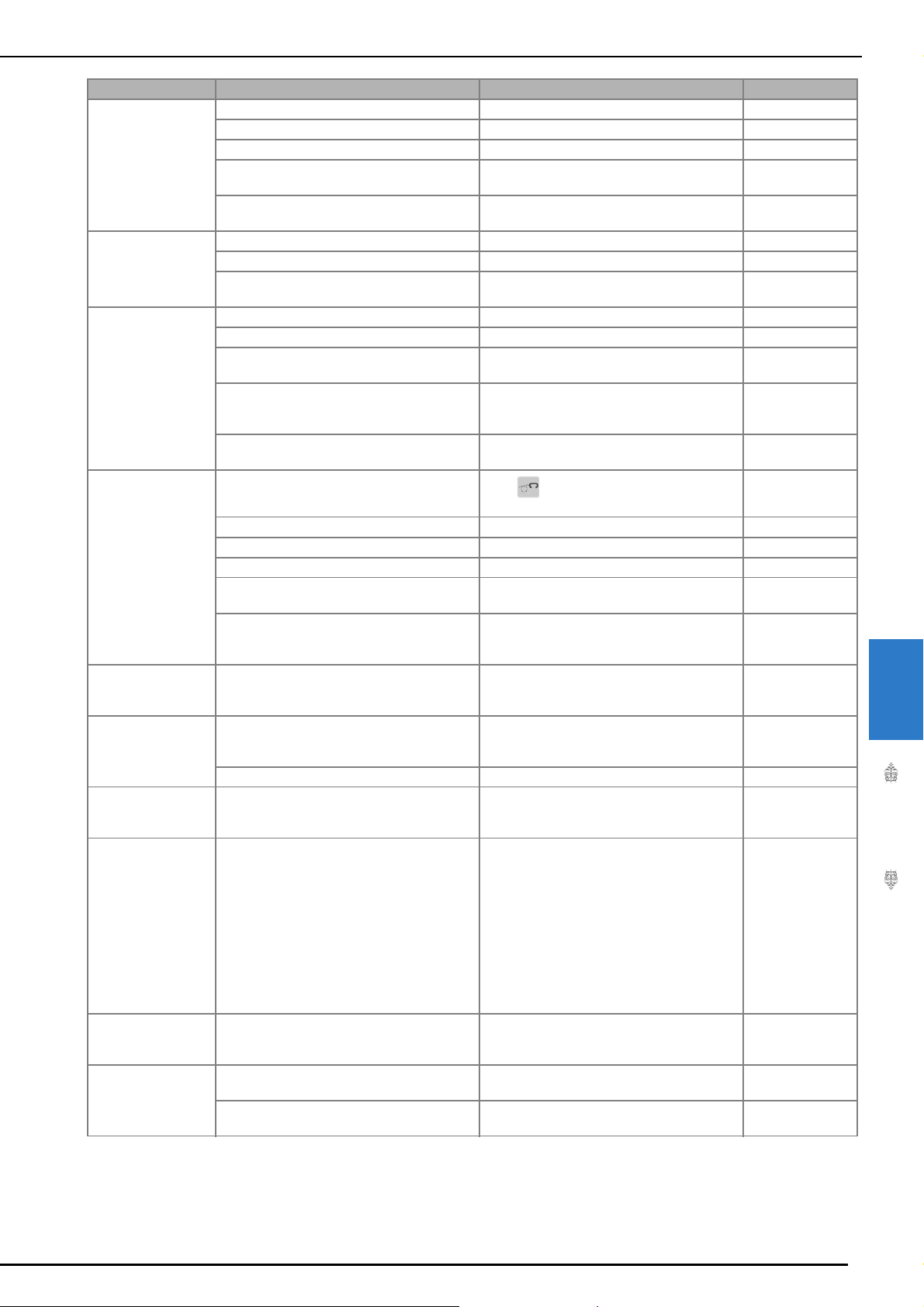

TROUBLESHOOTING

211

Appendix

6

Skipped stitches Needle is turned, bent or the point is dull. Replace the needle. 69

Needle is installed incorrectly. Reinstall the needle correctly. 69

Needle is defective. Replace the needle. 69

Dust or lint has collected under the needle

plate.

Remove the dust or lint with the brush. 198

Thin or stretch fabrics are being sewn. Sew with one sheet of thin paper under the

fabric.

84

No stitching Needle is turned, bent or the point is dull. Replace the needle. 69

Bobbin is set incorrectly. Reset the bobbin thread correctly. 58

Upper threading is incorrect. Check the steps for threading the machine and

rethread the machine.

61

High-pitched sound

while sewing

Dust or lint is caught in the feed dogs. Remove the dust or lint. 198

Pieces of thread are caught in the race. Clean the race. 198

Upper threading is incorrect. Check the steps for threading the machine and

rethread the machine.

61

A bobbin designed specifically for this

machine is not used.

Incorrect bobbins will not work properly. Only

use a bobbin designed specifically for this

machine.

58

There are needle holes or friction scratches in

the bobbin case.

Replace the bobbin case, or consult your

authorized Brother dealer.

198

Fabric does not feed

through the machine.

Feed dogs are set in the down position.

Press , and then turn the handwheel to

raise the feed dogs.

126

Stitches are too close together. Lengthen the stitch length setting. 86

Wrong presser foot was used. Use the correct presser foot.

218

Needle is turned, bent or the point is dull. Replace the needle. 69

Thread is entangled. Cut the entangled thread and remove it from

the race.

—

Zigzag foot “J” is slanted on a thick seam at

the beginning of stitching.

Use the presser foot locking pin (black button

on the left side) on zigzag foot “J” to keep the

presser foot level while sewing.

83

The fabric feeds in

the opposite

direction.

The feed mechanism is damaged. Contact your authorized Brother dealer.

—

The needle contacts

the needle plate.

The needle clamp screw is loose. Firmly tighten the needle clamp screw. If the

needle is bent or blunt, replace it with a new

one.

70

Needle is turned, bent or the point is dull. Replace the needle. 69

Fabric being sewn

with the machine

cannot be removed.

Thread is tangled below the needle plate. Lift up the fabric and cut the threads below it,

and clean the race.

202

A broken needle has

fallen into the

machine.

— Turn off the machine, and then remove the

needle plate. If the needle that fell into the

machine can be seen, use tweezers to remove

it. After removing the needle, return the needle

plate to its original position.

Before turning on the machine, slowly turn the

handwheel toward you to check that it turns

smoothly. If the handwheel does not turn

smoothly or the needle that fell into the

machine cannot be removed, consult your

authorized Brother dealer.

—

The handwheel feels

sluggish when it is

turned.

Thread is tangled in the bobbin case. Remove the tangled thread from the bobbin

case. Re-install the bobbin case so it is

correctly positioned.

202

The built-in camera

cannot detect the

buttonhole foot.

The buttonhole foot is dirty. Clean the area of the buttonhole foot to be

detected.

141

Mark “A+” or 3 dots on the presser foot is

shaded.

Keep these area clean. 141

Problem Cause Solution Page

Loading ...

Loading ...

Loading ...