Loading ...

Loading ...

Loading ...

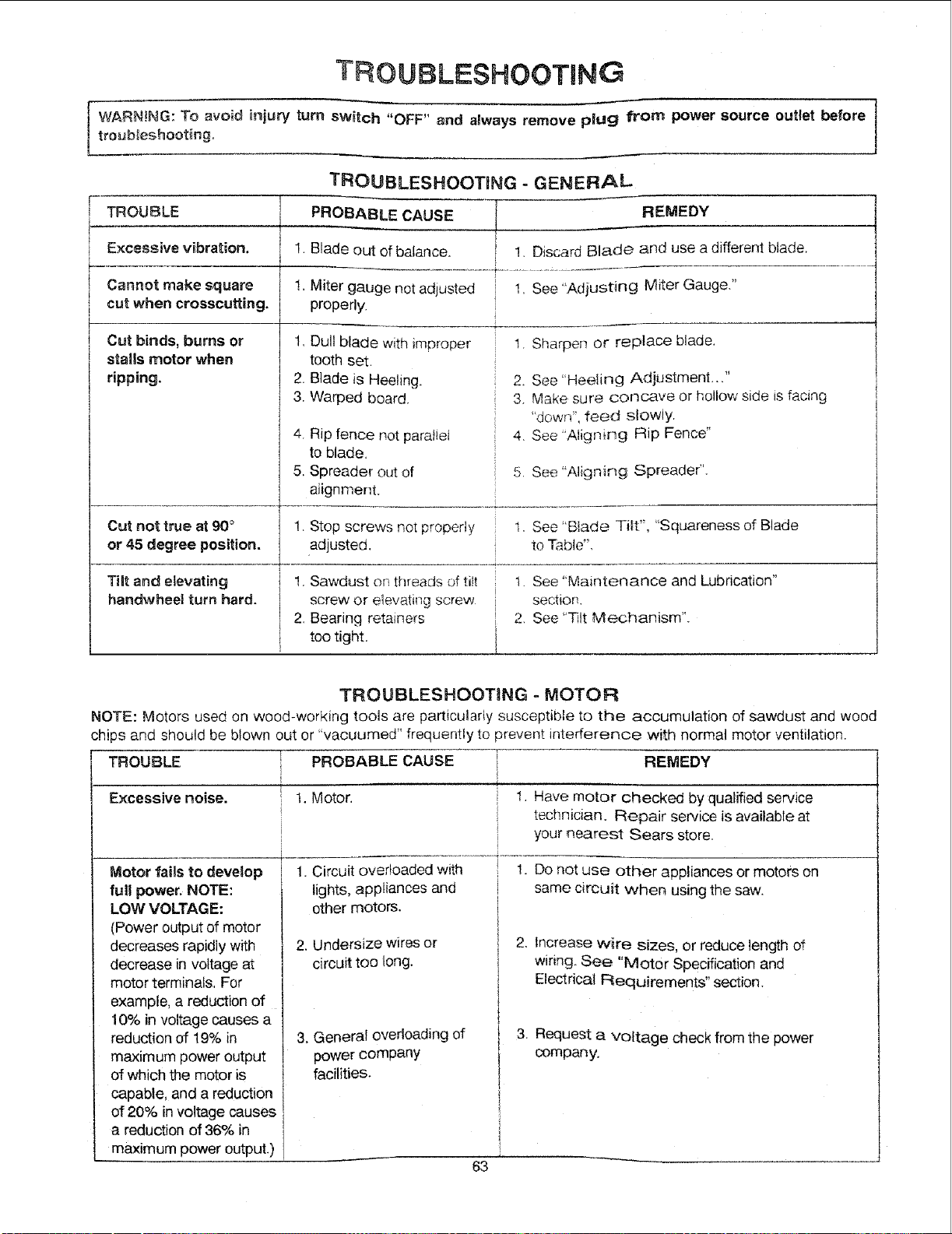

TROUBLESHOOTmNG

WARN!NG: To avoid injury turn switch "OFF" and always remove plug from power source outlet before I

troubleshooting,

J

TROUBLE

Excessive vibration. !.

Cannot make square !.

cut when crosscutting.

Cut binds, burns or 1,

stalls motor when

ripping. 2.

3.

4_

5.

Cut not true at 90 °

or 45 degree position.

TROUBLESHOOTING - GENERAL

PROBABLE CAUSE REMEDY

Blade out of balance, 1, Discard Blade and use a different blade,

.............................................. i................ :.................

Miter gauge not adjusted 1, See "Adiusting Miter Gauge,"

properly.

1. Sharpen or replace blade,Dull blade with improper

tooth set.

Blade is Heeling.

Warped board.

Rip fence not paratiei

to blade.

Spreader out of

alignment.

2. See "Heeling Adjustment..."

3. Make sure concave or hollow side is facing

"down', feed slowly.

4. See "AlignirTg Rip Fence"

5. See "Aligning Spreader".

1. Stop screws not property 1. See "Btade Tilt", "Squareness of Blade

adjusted, to Table",

Tilt and elevating

handwheel turn hard.

1. Sawdust or! threads of tiit

screw or elevatir, g screw

2. Bearing retainers

too tight.

1. See "Maintenance and Lubrication"

section.

2, See 'qqtt Mechanism".

TROUBLESHOOTING - MOTOR

NOTE: Motors used on wood-working tools are particular!y susceptible to the accumulation of sawdust and wood

chips and should be blown out or "vacuumed" frequently to prevent interference with normal motor ventilation.

TROUBLE I PROBABLE CAUSE TI

Excessive noise. 1. Motor.

Motor fails to develop

full power. NOTE:

LOW VOLTAGE:

(Power output of motor

decreases rapidly with

decrease in voltage at

motor terminals. For

example, a reduction of

10% in voltage causes a

reduction of 19% in

maximum power output

of which the motor is

capable, and a reduction

of 20% in voltage causes

a reduction of 36% in

maximum power output.)

1. Circuit overloaded with

lights, appliances and

other motors.

2. Undersize wires or

circuit too long.

3. General overloading of

REMEDY

t, Have motor checked by qualified service

technician. Repair service is available at

your nearest Sears store.

1. Do not use other appliances or motors on

same circuit when using the saw.

2. Increase w_re sizes, or reduce length of

wiring. See "Motor Specification and

Electrical Requirements" section.

power company

facilities,

3. Request a voltage check from the power

company.

63

Loading ...

Loading ...

Loading ...