Loading ...

Loading ...

Loading ...

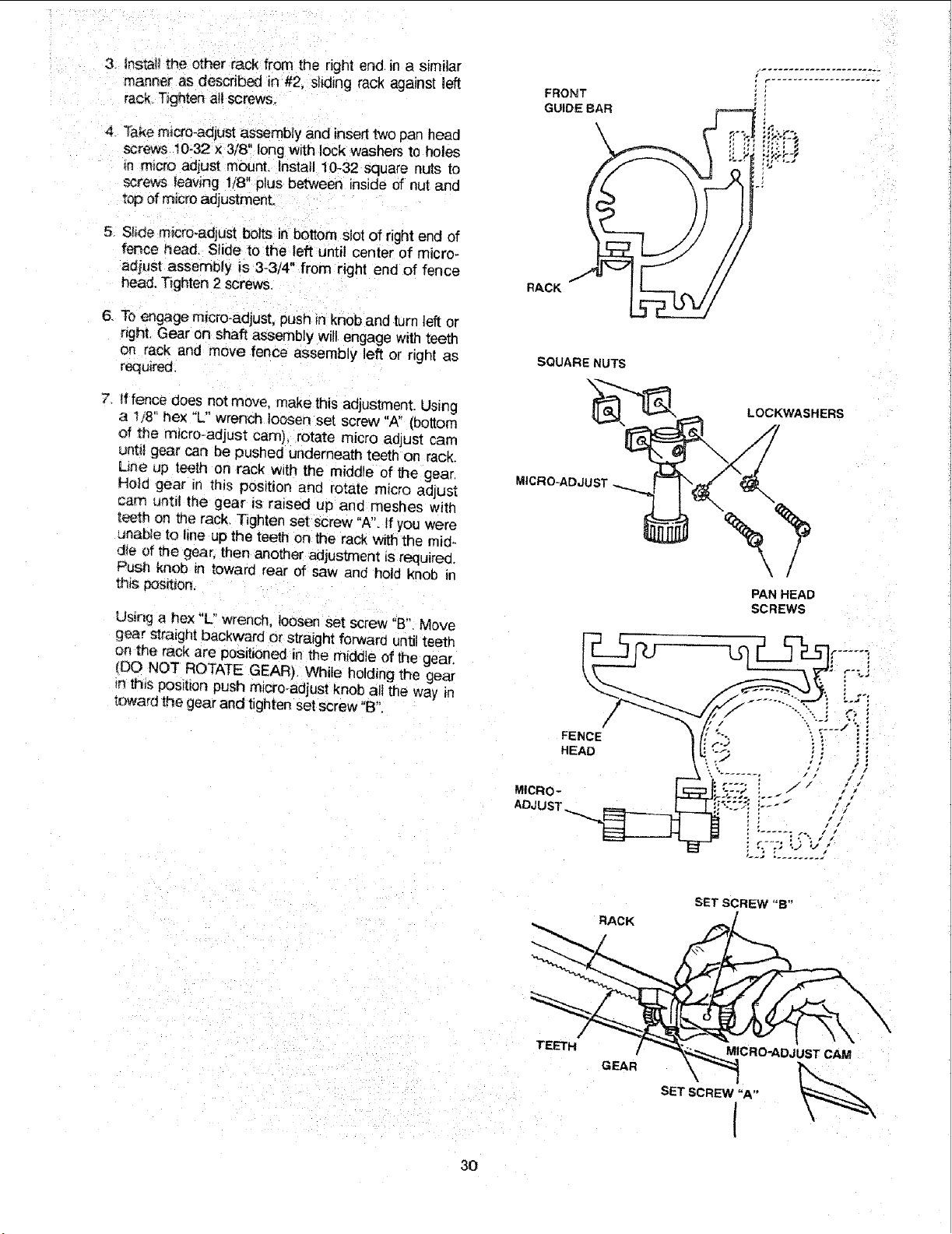

3 instanttheotherrackfromtherightendina similar

mannerasdescribedin #2.slidingrackagainstleft

rack.Tightenattscrews.

4 _akemicro-adjustassemblyandinserttwopanhead

screws10-32x 3/8"longwithlockwashersto holes

mm,,croadjustmount.Install10-32squarenutsto

screwsleaving1/8"plusbetweeninsideof nutand

topofmicroadjustmenL

5. Slidemicro-adjustboltsinbottomslotofrightendof

fencehead.Slideto theleftuntilcenterof micro-

adjustassemblyis 3-3/4"fromrightendof fence

head.Tighten2 screws.

6. Toengagemicro-adjust,pushinknobandturnleftor

right.Gearonshaftassemblywillengagewithteeth

on rackandmovefenceassemblyleftor rightas

required.

7 fffencedoesnotmove,makethisadjustment.Using

a 1/8"hex"L" wrench loosen set screw "A" (bottom

of the m_cro-adjust cam), rotate micro aGjust cam

until gear can be pushed underneath teeth on rack.

Line up teeth on rack w_th the middle of the gear.

Ho_d gear in this position and rotate micro ad ust

cam until the gear is raised up and meshes with

t_th on me rack. Tighten set screw "A". If you were

unable to line up the teeth on the rack with the mi@

die of me gear, then another adjuslment _srequired.

Push knob tn toward rear of saw and hold knob in

this pos_t_on.

Using a hex "L" wrench, loosen set screw "B" Move

gear straight backward or straight forward until teeth

on _e rack are positioned in the middle of the gear.

(DO NOT ROTATE GEAR). While holding the gear

{nthis POSrltonpush micro_adjust knob all the way _n

toward the gear and tighten set screw "B".

FRONT

GUIDE BAR

\

RACK

SQUARE NUTS

CRO-ADJUST

FENCE

HEAD

MICRo-

ADJUST

2i

LOCKWASHERS

PAN HEAD

SCREWS

RACK

SET SCREW "B"

TEETH

GEAR

MICRO-ADJUST CAM

SET SCREW "A"

I

30

Loading ...

Loading ...

Loading ...