Loading ...

Loading ...

Loading ...

4. Plan the way you wlll push the workplece

through.

NEVER pull the workplece through. Start and

finish _e clot from the front of the table saw.

NEVER put your fingers or hands in the path

of the sawt_ade or other cutting too!.

NEVER reach in back of the cutting tool with

e_ther hand to hold down or support the work-

p_ece remove wood scraps, or for any other rea-

son.

Avoid hand pos_ons where a sudden s!ip could

cau_ fingers or hand to move _nto a sawblade or

oth,_" cutt=ng tO01

DON_ OVERREACH. AJways Keep good footing

an_ batance.

Push the workp_ece against the rotation of the

b_ade. NEVER feed materia! into the cutting tool

from tt_e rear of the saw.

Nways push the workp_ece all the way past the

As much as moss_bteoke_,_ your face and body to

one s_de of the _wbtade out of lille with a poss_-

t_e kickback or throwback

NEVER turn the saw "ON' before clearing the

tabte of atl tools, wood scraps etc exceot the

workp_ece and related fc_l or support devtce.s for

me cut ptanned

AVOID ACCIDENTAL, STARTING o Make sure

switch is "OFF" before plu.cLqing saw in.

WHENEVER SAW IS RUNNING

WARNING: Don't let familiarity (gained from

frequent use of your table saw) cause a care-

_ess mistake. Always remember that a careless

fraction of a second is enough to cause a

severe injury.

t. Baler÷ aclualiy cutting w_th the saw, watc_ it while _t

runs for a short wh_ie If i! makes an unfarnihar no_se

or vibrates a tot, stoo immediately. Turn the ,_w eft,

Unplug the saw, Do not restart unt_t finding and fixing

the problemo

2. Make sure the top of the arbor or cu11_ng tool turns

toward the front of the saw.

3, Set the cutting tool as tow as possible for the cuz

you're planning.

4. KEEP CHILDREN AWAY. All ws_tors should be kept

a safe distance from work. MaKe sure bystanders

are c4ear of the saw and workp_ece

5. Let, #_e blade reach full sp_ before cutting,

& DON'T FORCE TOOL. !t wilt do the job be_er and

safer at _ts designed rate. Feed the workp_ece rote

the b{ade only fast enougr_ to let it cut without bog-

g_ng down or binding.

7. Before freeing any jammed material:

a Turn switch "OFF".

b Unplug the saw

c Wa_t for all moving parts to stop.

u, Check biade. Spreader a_d Fe_sce re: proper

a_gnrnent before slar_ir_g, _._f_an

8. To avoid throwback of cut off p;e,ces:

a. Use _ne G_4ard assemby.

h. To remove pt6wsesbeneath or trappecl ms,de the

Guard.

Turn saw "OFFL

2 Remove switch key.

3 Unplug saw,

4. Wa_t for blade to stop before !_fl_n9 the 9_sard.

Additional Instructions for

RiP TYPE CUTS

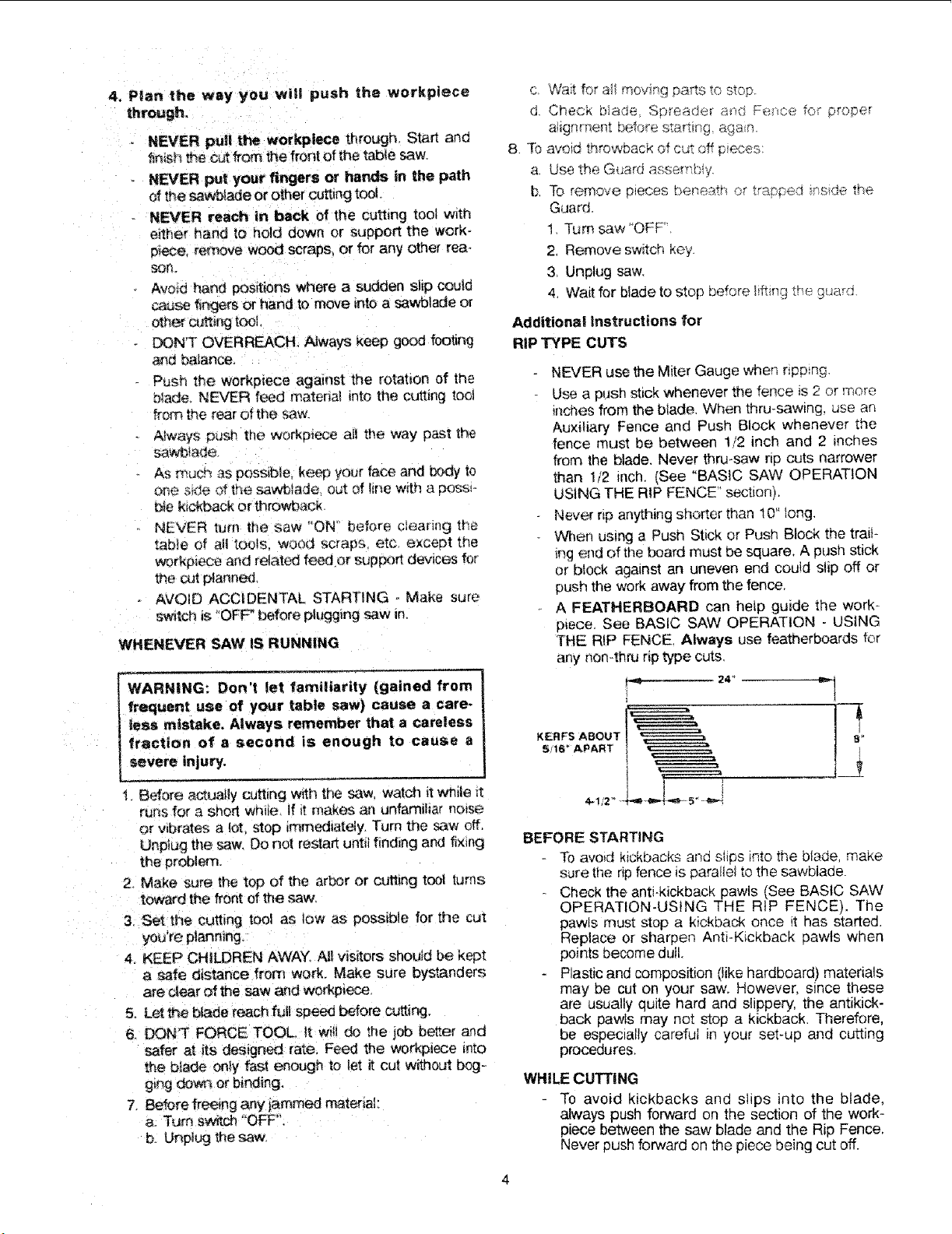

KERFS ABOUT

5/16" APART

9

NEVER use the Miter Gauge when npp_ng,

Use a push stick whenever the fence is 2 or more

inches from the blade When thru-sawing, use an

Auxiliary Fence and Push Block whenever the

fence must be between 1/2 inch and 2 inches

from the blade, Never thru-saw rip cuts narrower

_an 1/2 inch. (See "BASIC SAW OPERATION

USING THE RIP FENCE' section),

Never rip anything shorter than 10" tong,

When using a Push Stick or Push Block the trail-

_ng end of the board must be square, A push stick

or block against an uneven end could slip off or

push the work away from the fence,

A FEATHERBOARD can hetp guide the work-

p_ece See BASIC SAW OPERATION - USING

THE RiP FENCE. Always use featherboards for

any non4f_ru rip type cuts.

24 _

BEFORE STARTING

-[b avoid kickbacks and slips into the blade, make

sure the rip fence is parallel to the sawblade.

Check the anti-kickback pawls (See BASIC SAW

OPERATION-USING THE RiP FENCE). The

pawls must stop a kickback once it has started.

Replace or sharpen Anti*Kickback pawls when

points become dull.

Plastic and composition (like hardboard) materials

may be cut on your saw. However, since these

are usually quite hard and slippery, the antikick-

back pawls may not stop a kickback. Therefore,

be especially careful in your set-up and cutting

procedures.

WHILE CUTTING

To avoid kickbacks and slips into the blade,

always push forward on the section of the work-

piece between the saw blade and the Rip Fence.

Never push forward on the piece being cut off.

Loading ...

Loading ...

Loading ...