Loading ...

Loading ...

Loading ...

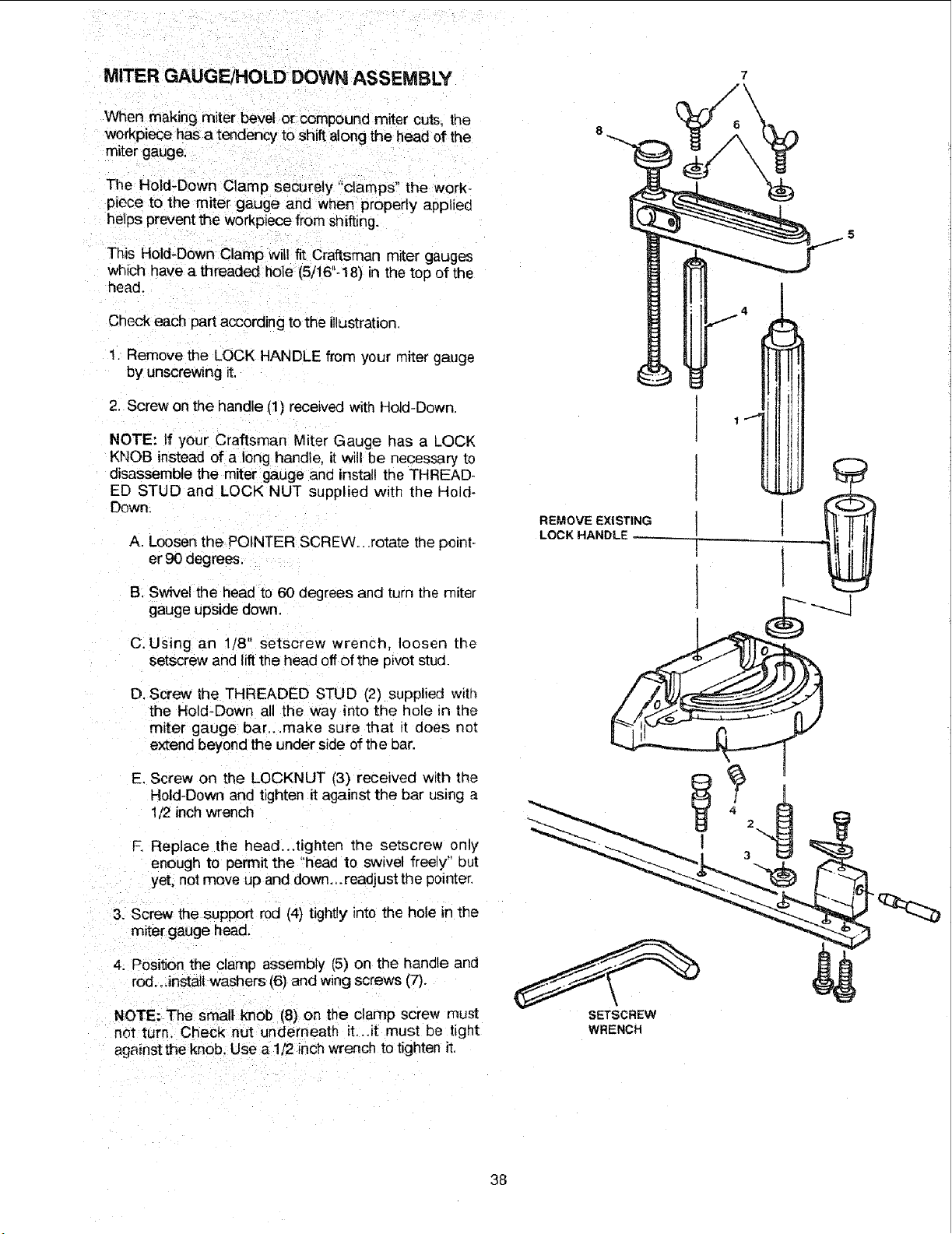

MITER GAUGF.JHOLD DOWN ASSEMBLY 7

When making miter bevel or compound miter cuts, the

workpiece has a tendency to shift along the head of the

miter gauge.

The Hold-Down Clamp securely "clamps" the work.

piece to the miter gauge and when properly applied

helps prevent the workpiece from shifting.

This Hold-Down Clamp will fit Craftsman miter gauges

which have a threaded hole (5/16"-18) in the top of the

head.

Check each part according to the illustration.

I Remove the LOCK HANDLE from your miter gauge

by unscrewing it.

2. Screw on the handle (1) received with Hold-Down.

NOTE: If your Craftsman Miter Gauge has a LOCK

KNOB instead of a long handle, it will be necessary to

disassemble the miter gauge and install the THREAD-

ED STUD and LOCK NUT suppliec with the Hold-

Down.

A. Loosen the POINTER SCREW...rotate the point-

er 90 degrees.

B, Swivel the head to 60 degrees and turn the miter

gauge upside down.

C. Using an 1/8" setscrew wrench, loosen the

setscrew and lift the head off of the pivot stud.

D. Screw the THREADED STUD (2) supplied with

the Hold-Down all the way into the hole in the

miter gauge bar.,.make sure that t does not

extend beyond the under side of the bar.

E. Screw on the LOCKNUT (3) received with the

Hold-Down and tighten it against the bar using a

1/2 inch wrench

F. Replace the head...tighten the setscrew only

enough to permit the "head to swivel freely" out

yet, not move up and down_.readjust the pointer.

3. Screw the support rod (4) tightly into the hole in the

miter gauge head,

4. Position the clamp assembly (5) on the handle and

rod.. Jnstal_washers (6) and wing screws (7).

NOTE: The small knob (8) on the clamp screw must

not turn. Check nut underneath it, ..it must be tight

against the knob, Use a 1/2 inch wrench to tighten it.

REMOVE EXISTING

LOCK HANDLE

SETSCREW

WRENCH

38

Loading ...

Loading ...

Loading ...