Loading ...

Loading ...

Loading ...

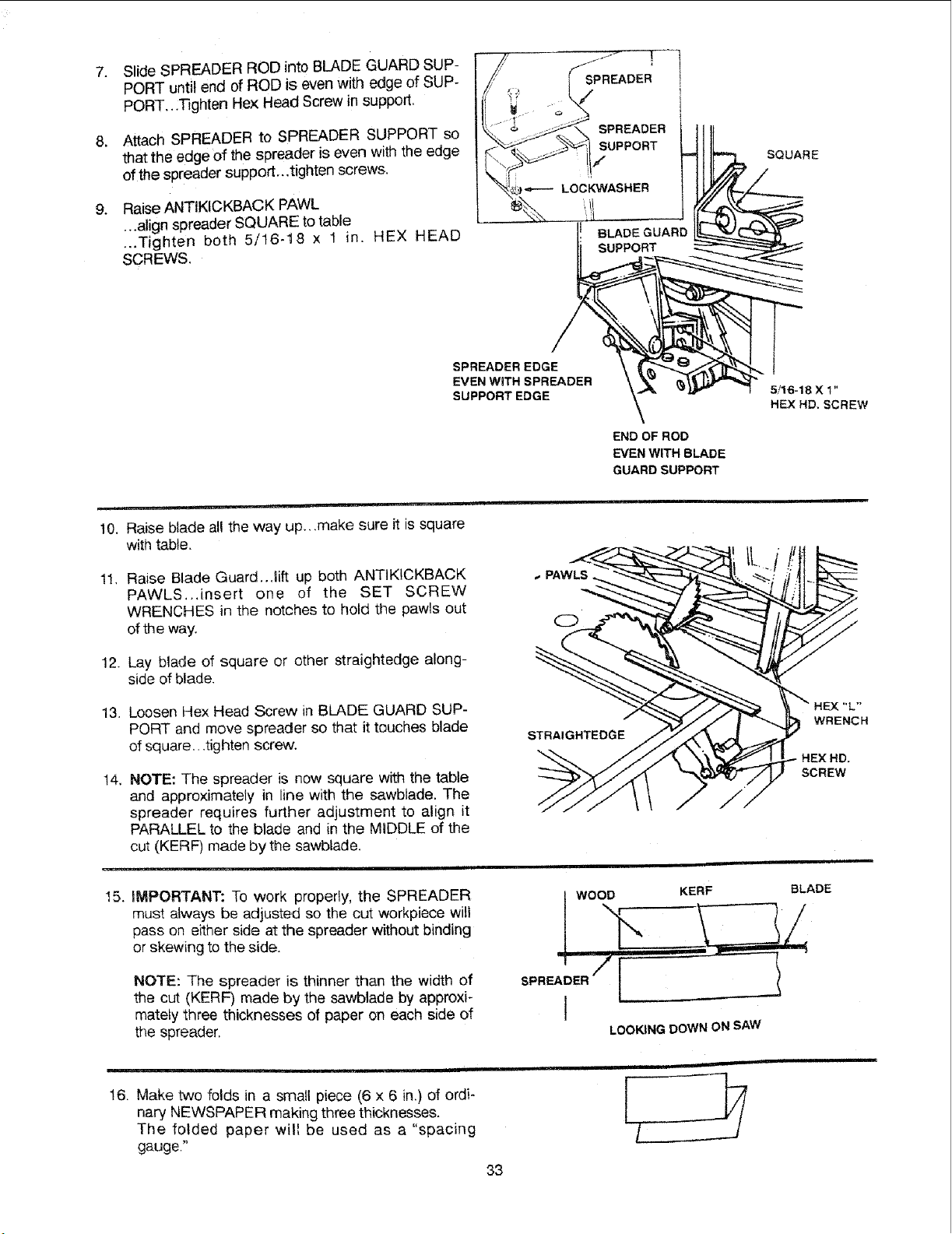

7.

.

Slide SPREADER ROD into BLADE GUARD SUP-

PORT until end of ROD is even with edge of SUP-

PORT,.,lqghten Hex Head Screw in support.

Attach SPREADER to SPREADER SUPPORT so

that the edge of the spreader is even with the edge

of the spreader support...tighten screws.

Raise ANTIKICKBACK PAWL

...align spreader SQUARE to table

..,Tighten both 5/t6-18 x 1 in. HEX HEAD

SCREWS.

SQUARE

SPREADEREDGE

EVEN WITH SPREADER

SUPPORT EDGE

5/16-18 X 1"

HEX HD. SCREW

END OF ROD

EVEN WITH BLADE

GUARD SUPPORT

__ ,irl,

10. Raise blade all the way up., ,make sure it is square

with table.

11. Raise Blade Guard..Jift up both ANTIKICKBACK

PAWLS..Jnsert one of the SET SCREW

WRENCHES in the notches to hold the pawls out

of the way.

12. Lay blade of square or other straightedge along-

side of blade.

13. Loosen Hex Head Screw in BLADE GUARD SUP-

PORT and move spreader so that it touches blade

of square...tighten screw.

14, NOTE: The spreader is now square with the table

and approximately in line with the sawblade. The

spreader requires further adjustment to align it

PARALLEL to the blade and in the MIDDLE of the

cut (KERF) made by the sawblade.

15. iMPORTANT: To work properly, the SPREADER

must always be adjusted so the cut workpiece will

pass on either side at the spreader without binding

or skewing to the side.

NOTE: The spreader is thinner than the width of

the cut (KERF) made by the sawblade by approxi-

mately three thicknesses of paper on each side of

the spreader.

WOOD

SPREADER I

I

KERF BLADE

LOOKING DOWN ON SAW

!6. Make two folds in a small piece (6 x 6 in.) of ordi-

nary NEWSPAPER making three thicknesses.

The folded paper will be used as a "spacing

gauge."

__ iiiii

i

33

Loading ...

Loading ...

Loading ...