Loading ...

Loading ...

Loading ...

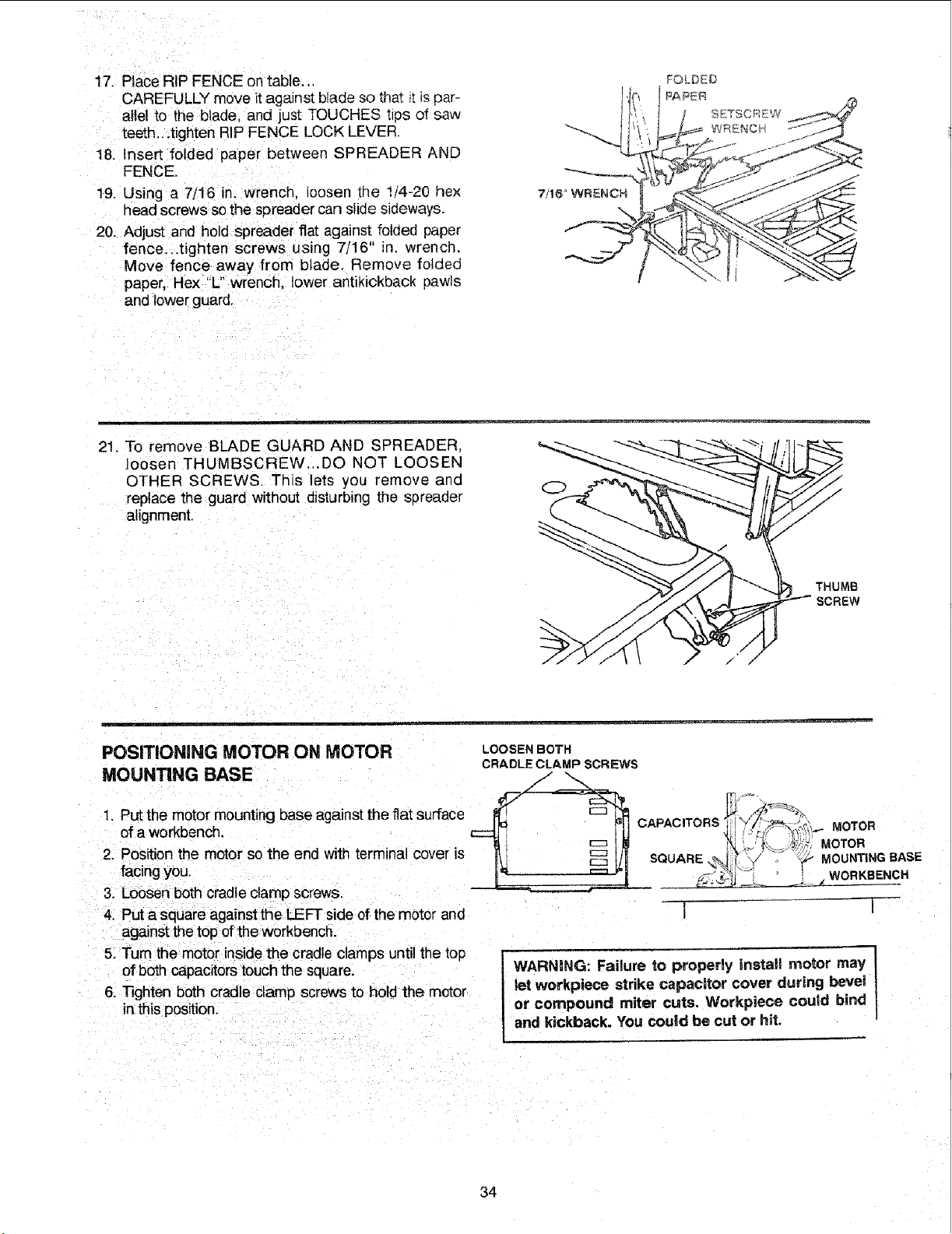

17.PlaceRIPFENCEontable.,,

CAREFULLYmoveitagainstbladesothat_tispar-

alle!to theblade,andjustTOUCHEStipsof saw

teeth...tightenRIPFENCELOCKLEVER.

18.InsertfoldedpaperbetweenSPREADERAND

FENCE.

19.Usinga 7/16in.wrench._oosenthe 1/4-20hex

headscrewssothespreadercanslidesideways.

20.Adjustandholdspreaderflatagainstfoldedpaper

fence...tightenscrewsusing7/16"in. wrench.

Movefenceawayfromblade.Removefolded

paper,He)("L" wrench, lower antikickback pawls

and lower guard.

7/16 WRENCH

\

FOLDED

21. To remove BLADE GUARD AND SPREADER,

loosen THUMBSCREW_.DO NOT LOOSEN

OTHER SCREWS. This lets you remove and

replace the guard without disturbing the s_)reader

alignment.

THUMB

SCREW

POSITIONING MOTOR ON MOTOR

MOUNTING BASE

1, Put the motor mounting base against the fiat surface

of a workbench.

2. Position the motor so the end with terminal cover is

facing you.

3. Loosen both cradle clamp screws,

4. Put a square against the LEFT side of the motor and

against the top of the workbench.

5. Turn the motor inside the cradle clamps until the top

of both capacitors touch the square.

6. Tighten both cradle clamp screws to hold the motor

in this position.

LOOSEN BOTH

CRADLE CLAMP SCREWS

CAPACWORS t l I/"L._,-_,,_,,_%_. MOTOR

_-];4-_, _ k---Z- WORKBENCH

1 !

WARNING: Failure to properly install motor may ]

let werkpiece strike capacitor cover during bevet |

or compound miter cuts. Workpiece could bind l

and kickback. You could be cut or hit.

34

Loading ...

Loading ...

Loading ...