Loading ...

Loading ...

Loading ...

2 ELEVATION HANDWHEEL...elevates or lowers the

blade_ Turn clockwise to elevate, counterclockwise

to lower.

NOTE: Any t_me sawblade has been etevated to 2-

5!8 inches or h_gher above the table _ w_Ii be neces-

sary to _ower the btade by turn_ng me elevation

handvtC_eel 5 turns counterclockwise before tilting to

bevel

3 TILT HANDVtt'HEEL.,tilts the blade for bevel cut-.

t_ng Turn clOCkwise to tilt toward tuft_ .counterclock-

wise to titt toward vertical.

When the blade iS tilted to me LEFT as far as _t w_II

go. _t should be at 45 degrees to the table and T.ne

beve_ indicator should point 45 degrees,

NOTE: There are LIMIT STOPS on the saw whsch

prevent the blade from tilting beyond 45 degrees to

the LEFT and 90 degrees to the RIGHT, (See

"Adjustment" section "Blade Tilt, or Squareness of

B_ade to Table'1.

4 TILT LOCK HANDLE., ,locks the blade in the

desired tilt position. To loosen, turn counterclock-

wise. Push handle in and turn it to another position if

necessary in order to tighten or loosen.

IMPORTANT: Be sure handle is hanging in the

"DOWfN" position before tilting blade. If it is

pointing to the 1 o'clock position it may jam on

underside of the table and bend the locking bolt.

5 RtP FENCE,.,Is locked in place by pushing the lock

lever down until the lever rests on the stop. To move

the fence, lift the lock lever and grasp the fence with

one hand at the front and then push fence left or

r_ght.

Slots are provided in the nD fence for altachmg a

wood facing when uslng the da.do heac or molding

head, featherboards or other l_gs and fixtures

Select a piece of smooth stratght wood approx. 3/4.

n. thick and the same length as the rip fence,

To fasten auxiliary face to the fence use 3 eacn,

t/4"-20 x 3/4" square head machine screws with

nuts, Counterbore 1" dta. hole 3/8" deep into the 3/4"

board at the designated dimensions,

CHANNEL FENCE

See Fig A. _4-AUX.FACE

t.,4_ HOLE JI"_L' I_J-'-_z_

Drill a 1/4"

I* X 3 8" DEEP

clearance hote _ _11[WtJ;,t-, SOUARENEAP

through the board. HE×_UT";_t JJ_ BOLT

_,.'.=o ' L-I

1" COUNTERBORE, WASHER

318_'DEEP 1'4"x ss*x 1;1_°

114= CLEARANCE ........... 34"

.....................

....... 18"

HOLE THROUGH i.6-.:

THE BOARD, WOODFACtNG

.... 3/40

............. 18" -................

........ 34 ...................... '

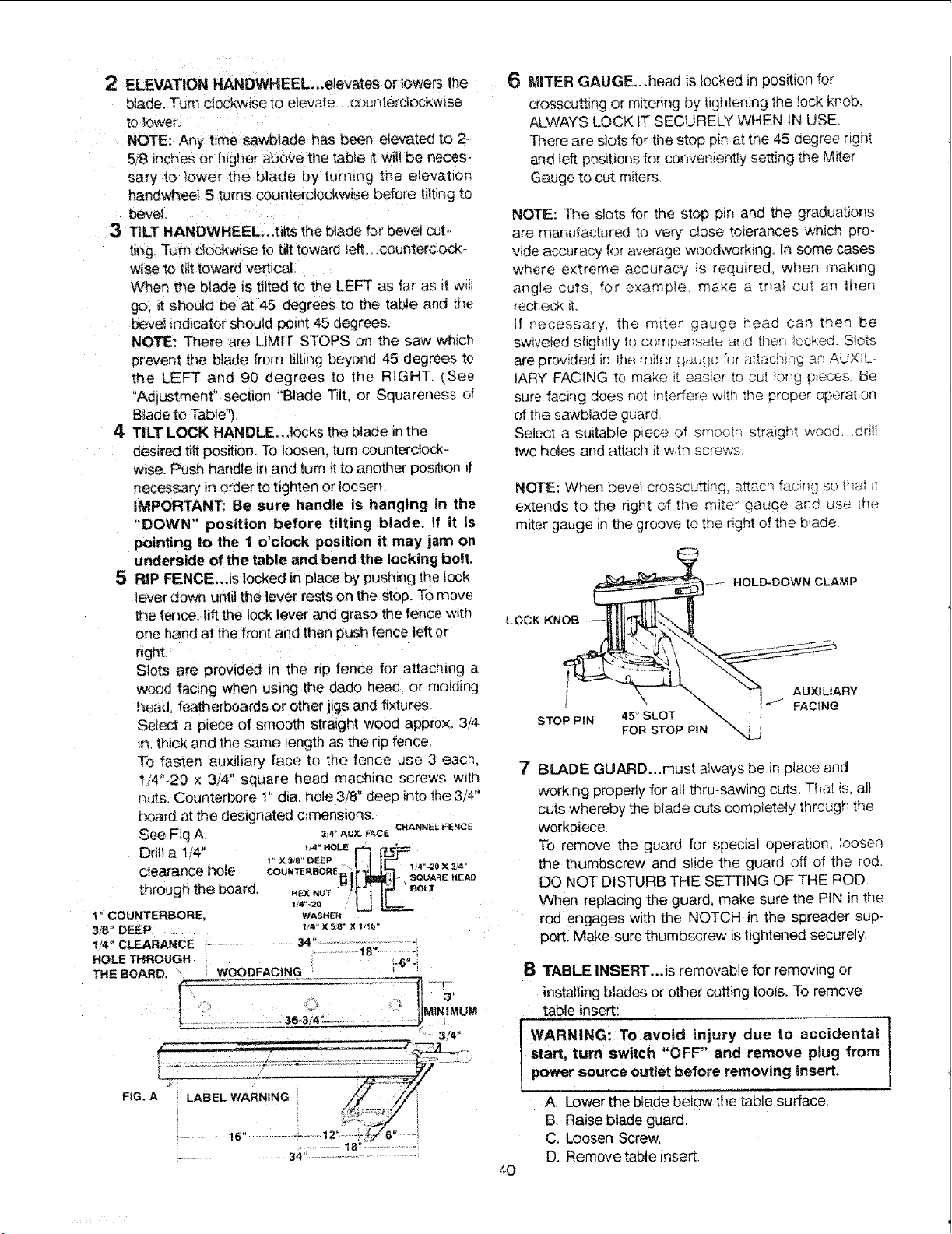

6 MITER GAUGE_.head is locked _nposition for

crosscut£ng or mitenng by t_ghteningthe !ock knob.

ALWAYS LOCK tT SECURELY WHEN IN USE.

There are slots for the stop p_nat the 45 degree right

and tuft pos_bonsfor conveniently setting the M_ter

Gauge to cut m_ters

NOTE: The slots for the stop p_n and the graduabons

are rnanufactured to very c_ose tolerances wn;cn pro-

vide accurNcy for average woodworking, in some cases

where extreme accuracy _s required when making

angle cuts for example make a tr_a_ cut an then

recheck _1.

If necessary, me m_ter gauge head can men be

swweied s!_ghtly to compensate ar;d men .ockea Slots

are provided in the m_ter qauqe for a_achin_ ar AUXIL-

IARY FAC!NG to make _, eas_er to cut _ong D_eces Be

sure facing does ncI ffqterfere wqn the orooer operation

of the sawb_ade guard

Select a suitable piece of srnocu straign_ wona. dnlt

two ho_es arid attach it w;th _crews

NOTE: When bevel crosscusing, attach fac.[_g s ___'_;T it

extends to the right of the m_ter gauge anc. use the

miter gauge m the groove to tne nght of the b!ade.

_.- HOLD-DOWN CLAMP

!__UXILIARY

; ..o_,_. _ -- I t.,.J FACING

STOP P_N 45_SLOT -_.

FOR STOP PIN "-

8 TABLE INSERT...Is removable for removing or

installing blades or other cutting tools. To remove

table insert:

WARNING: To avoid injury due to accidental

start, turn switch "OFF" and remove plug from

power source outlet before removing insert.

A Lower the blade below the table surface.

B. Raise blade guard.

C, Loosen Screw,

D. Remove table inset,

7

BLADE GUARD...must atways be in place and

working properly for aHthru-sawing cuts, That is, all

cuts whereby the blade cuts completely through the

workpiece,

To remove the guard for special operation, loosen

the thumbscrew and slide the guard off of the rod.

DO NOT DISTURB THE SETTING OF THE ROD.

When replacing the guard, make sure the PIN in the

rod engages with the NOTCH in the spreader sup-

portl Make sure thumbscrew is tightened securely.

40

Loading ...

Loading ...

Loading ...