Loading ...

Loading ...

Loading ...

Troubleshooting

110

Upper threading is incorrect. 25

Bobbin is set incorrectly. 23

Presser foot is attached incorrectly. 30

Screw of the presser foot holder is loose. 31

Fabric is too thick. 28, 42

Fabric is fed forcefully when sewing thick fabric or

thick seams.

42

Stitch length is too short. 39

Stabilizer is not attached to fabric being

embroidered.

80

Bobbin thread is incorrectly wound. 21

Upper thread breaks.

Machine is not threaded correctly (used the wrong

spool cap, spool cap is loose, the thread did not

catch the needle bar threader, etc.).

25

Knotted or tangled thread is being used. –

The selected needle is not appropriate for the

thread being used.

28

Upper thread tension is too tight. 39

Thread is tangled. 105

Needle is turned, bent or the point is dull. 29

Needle is installed incorrectly. 29

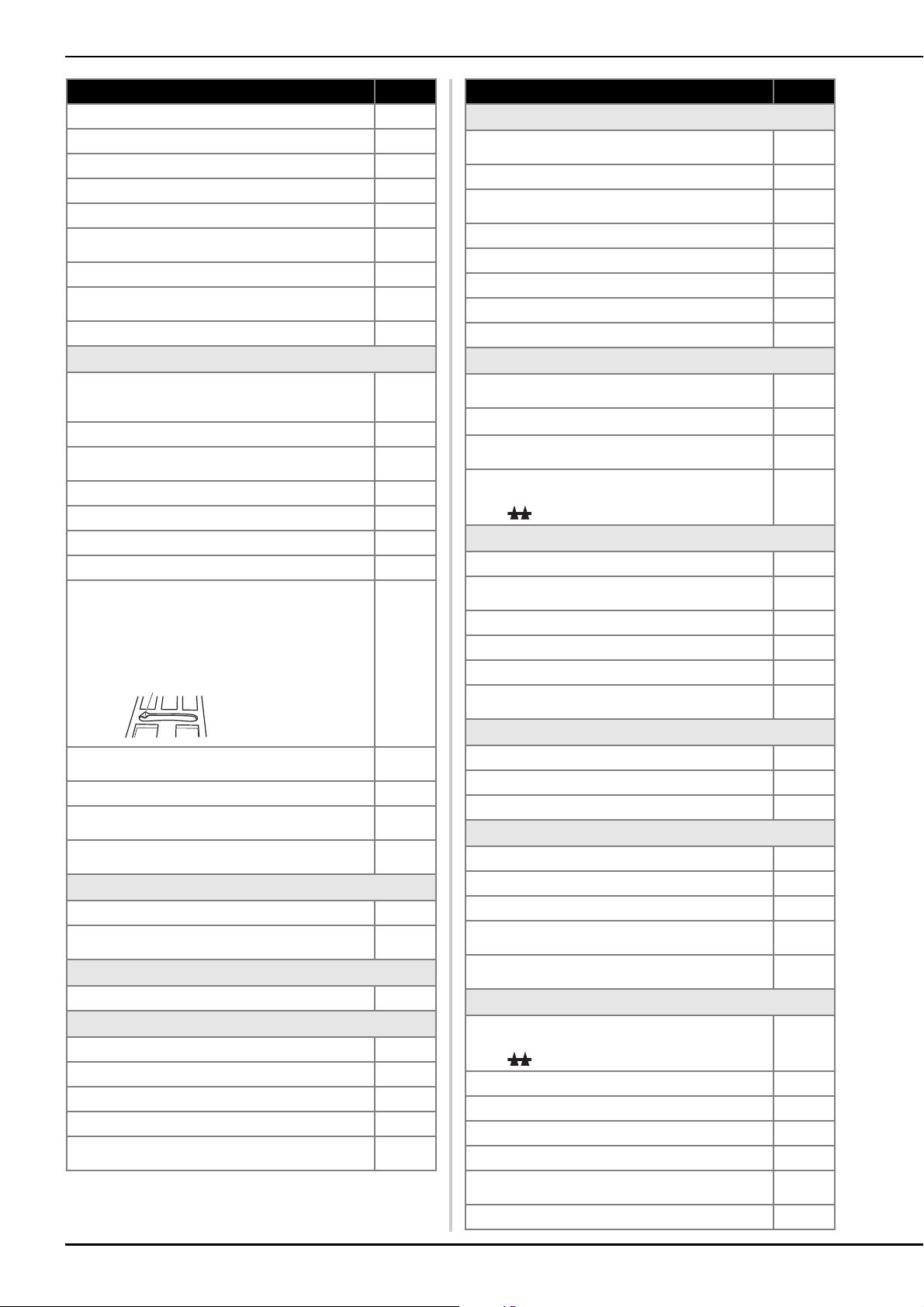

There are scratches around the opening in the

needle plate.

* There is a notch on the left side of the opening

in the needle plate. This is not a scratch.

*

There are scratches around the opening in the

presser foot.

*

There are scratches on the bobbin case. *

Using improper needle or thread for the selected

fabric.

28

A bobbin designed specifically for this machine is

not being used.

21

The thread is tangled on the wrong side of the fabric.

Upper threading is incorrect. 25, 105

Using improper needle or thread for the selected

fabric.

28

The upper thread is too tight.

The bobbin thread is incorrectly installed. 23

Bobbin thread breaks.

Bobbin is set incorrectly. 23

Bobbin thread is incorrectly wound. 21

A scratched bobbin is being used. 23

Thread is tangled. 106

A bobbin designed specifically for this machine is

not being used.

21

Symptom, Cause/solution

Reference

1 Notch

a

Fabric puckers.

There is a mistake in the upper or bobbin

threading.

21, 25

Spool of thread is set incorrectly. 21

Using improper needle or thread for the selected

fabric.

28

Needle is turned, bent or the point is dull. 29

Stitches are too long when sewing thin fabrics. 39

Thread tension is set incorrectly. 39, 106

Wrong presser foot was used. 30

The fabric is not pressed down correctly. –

The stitch is not sewn correctly.

The presser foot that is used is not appropriate for

the type of stitch that you wish to sew.

30

The thread tension is incorrect.

39, 106

The thread is tangled, for example, in the bobbin

case.

106

Feed dogs are set in the down position.

• Slide the feed dog position switch to the right

().

9, 64

Skipped stitches

Machine is threaded incorrectly. 21, 25

Using improper needle or thread for the selected

fabric.

28

Needle is turned, bent or the point is dull. 29

Needle is installed incorrectly. 29

Dust or lint has collected under the needle plate. 103

Thin or stretch fabrics are being sewn.

• Attach stabilizer material to the fabric.

42

Not stitching

Needle is turned, bent or the point is dull. 29

Bobbin is set incorrectly. 23

Upper threading is incorrect. 25

High-pitched sound while sewing

Dust or lint is caught in the feed dogs. 103

Pieces of thread are caught in the race. 103

Upper threading is incorrect. 25

A bobbin designed specifically for this machine is

not being used.

21

There are needle holes or friction scratches in the

bobbin case.

*

Fabric does not feed through the machine.

Feed dogs are set in the down position.

• Slide the feed dog position switch to the right

().

9, 64

Stitches are too close together. 39

Wrong presser foot was used. 30

Needle is turned, bent or the point is dull. 29

Thread is entangled. 106

Zigzag foot “J” is slanted on a thick seam at the

beginning of stitching.

42

Presser foot pressure is set incorrectly for fabric. 16

Symptom, Cause/solution

Reference

Loading ...

Loading ...

Loading ...