Loading ...

Loading ...

Loading ...

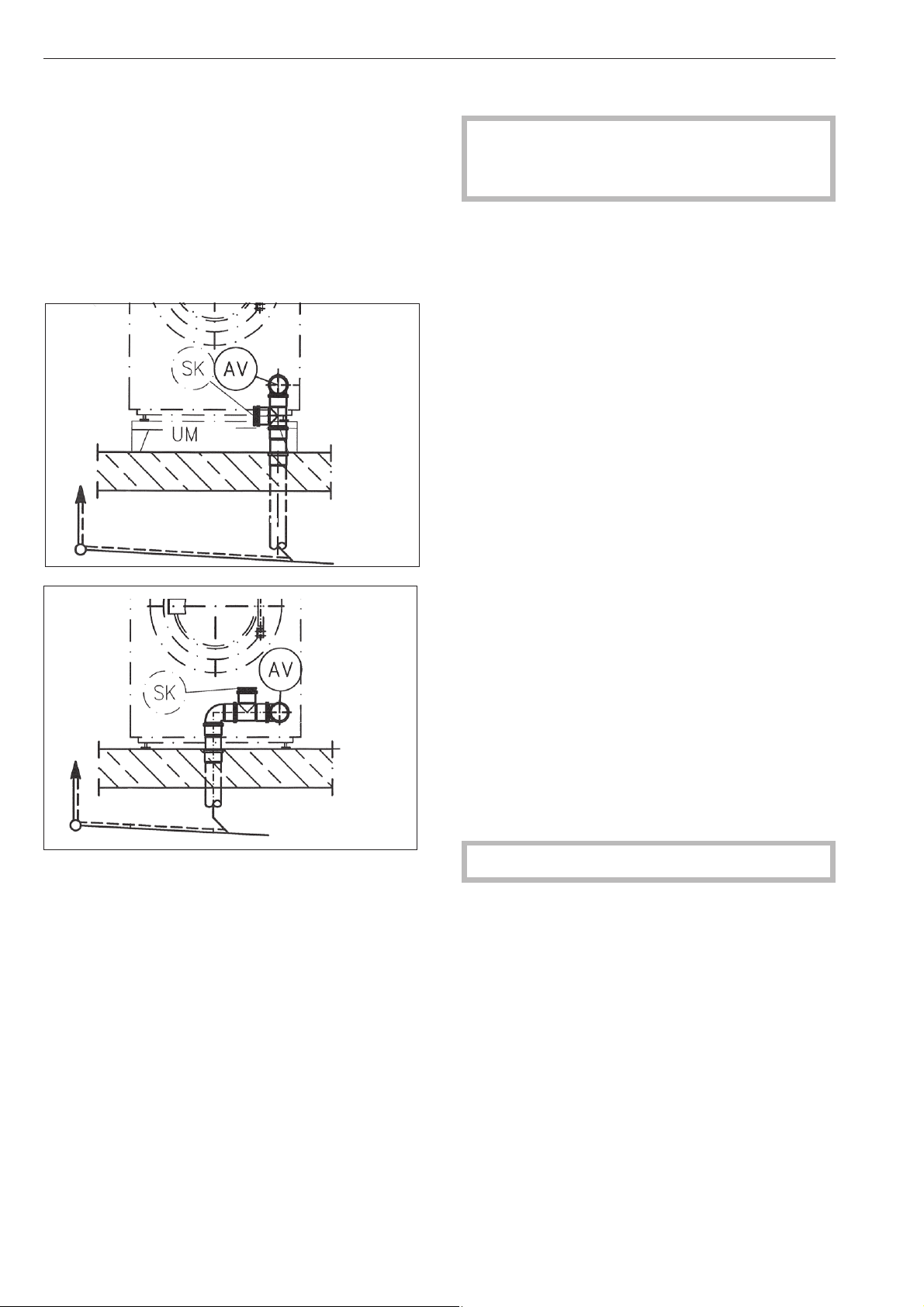

Water drainage

Dump valve drainage (AV) DN 70 on the machine

side, DN 70 socket on-site. Transient flow rate 200

l/min.

Foam compensator (SK)

Increased foaming can lead to foam being

discharged from the vapour vent. A drain with siphon

(commercial off-the-shelf pipe material) can be

retro-fitted to dispose of the foam.

Installation examples

Electrical connection

The electrical connection must only be carried out

by a suitably qualified electrician in accordance

with local and national safety regulations.

The connection terminal is located behind the cover.

The machine must only be connected to the voltage

and frequency shown on the data plate.

The machine is equipped with a multi-tap

transformer.

If the applicance is hard wired, a multi-pole separator

must be installed. An appropriate separator is a

switch with a contact opening of at least 1/8" (3 mm).

This includes circuit breakers, fuses and switches.

The plug connection or the separator must always be

accessible.

Connection should be made in accordance with the

wiring diagram and installation diagram to a suitable

isolator, with an on-off switch which is easily

accessible for servicing. The wiring and installation

diagrams are important for the correct electrical

functioning of the machine.

If the machine is disconnected from the electricity

supply ensure adequate measures are taken to

ensure that it cannot be reconnected to the electricity

supply until all work has been carried out.

Potential equalization

Potential equalization must be provided if the leak

current exceeds 10mA.

To activate the heating the water level in the drum

must be 2" (50cm) high.

A motor overload protection is located in the motor

winding.

See the enclosed wiring and installation diagrams.

Installation and connection

36

Loading ...

Loading ...

Loading ...