Loading ...

Loading ...

Loading ...

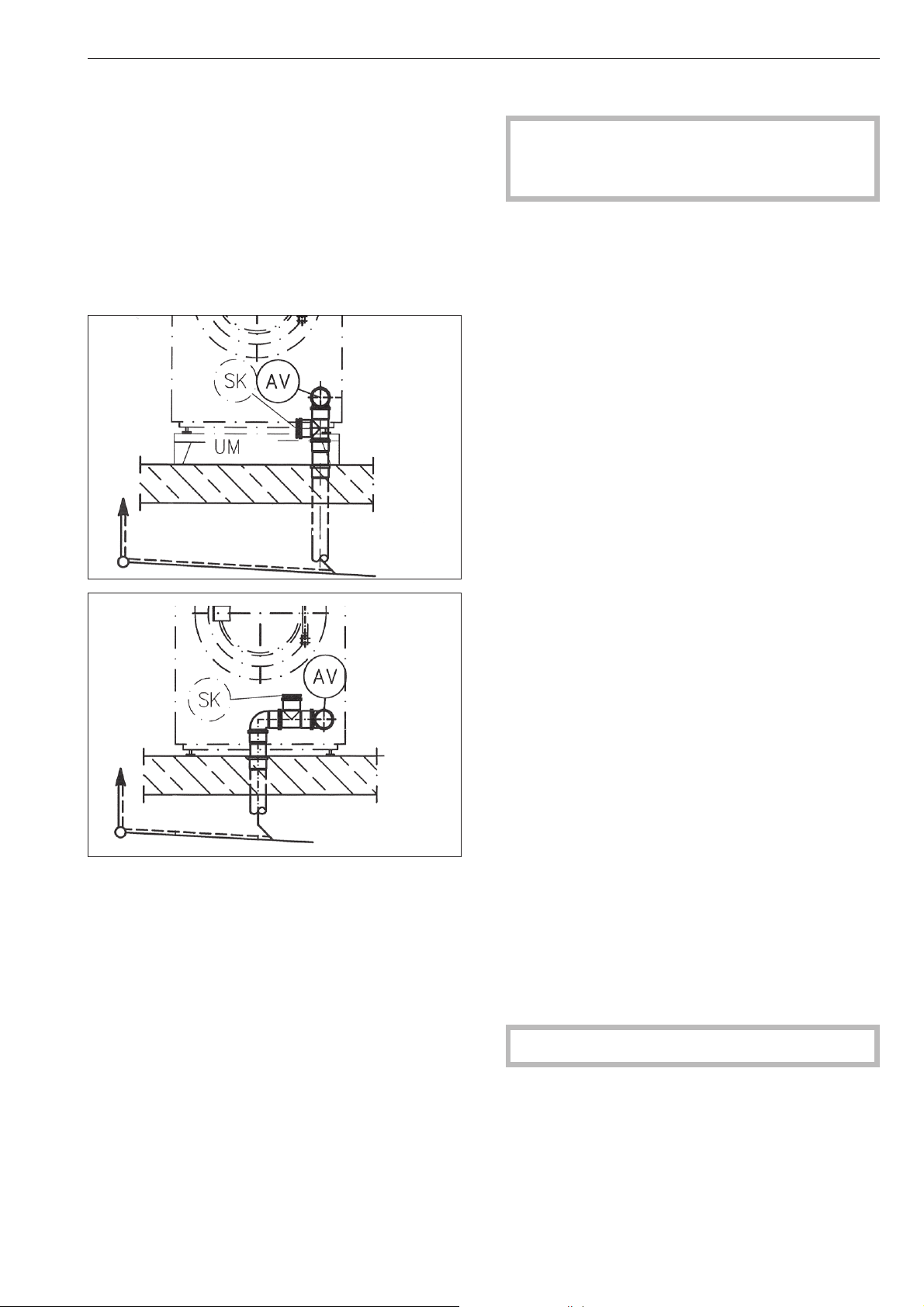

Water outlet

Water outlet AV is DN 70 on the machine, the fitting to

the machine is DN 70. Short-term thoughput 200

l/min.

Foam compensator SK

In the event of over sudsing, foam may escape

through the vapor vent. To drain the foam, a drain

with siphon can be fitted using off-the-shelf piping

materials.

Installation examples

Electrical connection

All electrical work must be performed by a

qualified service technician in accordance with

applicable codes and standards.

The connecting terminal is located behind the cover.

The machine must only be connected to the voltage

and frequency shown on the data plate.

The machine is equipped with a multi-tap

transformer.

Steam heated washers are factory set to 3 phase,

208 V, 60 Hz

They can be converted to 3 phase, 240 V, 60 Hz by a

Miele Service Technician.

Electrically heated washers are factory set to 3

phase, 230 V, 50/60 Hz

They can be converted to 3 phase, 208 V, 60 Hz by a

Miele Service Technician.

If the appliance is hard wired, a multiple-pole

separator must be installed. An appropriate separator

is a switch with a contact opening of at least 3 mm.

This includes circuit breakers, fuses and switches.

The plug connection or the separator must be always

be accessible.

Connection should be made in accordance with the

wiring diagram and the installation diagram to a

suitable isolator, with an on-off switch which is easily

accessible for servicing. These diagrams are

important for the correct electrical functioning of the

machine.

Potential equalization

A potential equalization must be provided if the leak

current is >10 mA.

The electric heating is factory-set to

9 kW PW 6107

15 kW PW 6137, PW 6167

18 kW PW 6207.

To activate the heating the water level in the drum

must be 2" (50 mm) high.

A motor overload protection is located in the motor

winding.

See the enclosed wiring and installation diagrams.

Installation Instructions

37

Loading ...

Loading ...

Loading ...