Loading ...

Loading ...

Loading ...

TROUBLESHOOTING

208

* Align the and ● marks.

a mark

b ● mark

c Bobbin case

* Make sure that the indicated points are aligned

before installing the bobbin case.

k

Insert the tabs on the needle plate into the

notches in the machine.

a Tabs

b Notches

l

Press down on the right side of the needle

plate to secure it.

m

Check the condition of the needle, and then

install it.

If the needle is in a poor condition, for example, if it is

bent, be sure to install a new needle.

* Refer to “CHANGING THE NEEDLE” on page 69.

■ Checking Machine Operations

If the needle plate has been removed, check

machine operations to confirm that installation has

been completed correctly.

a

Turn on the machine.

b

Select .

c

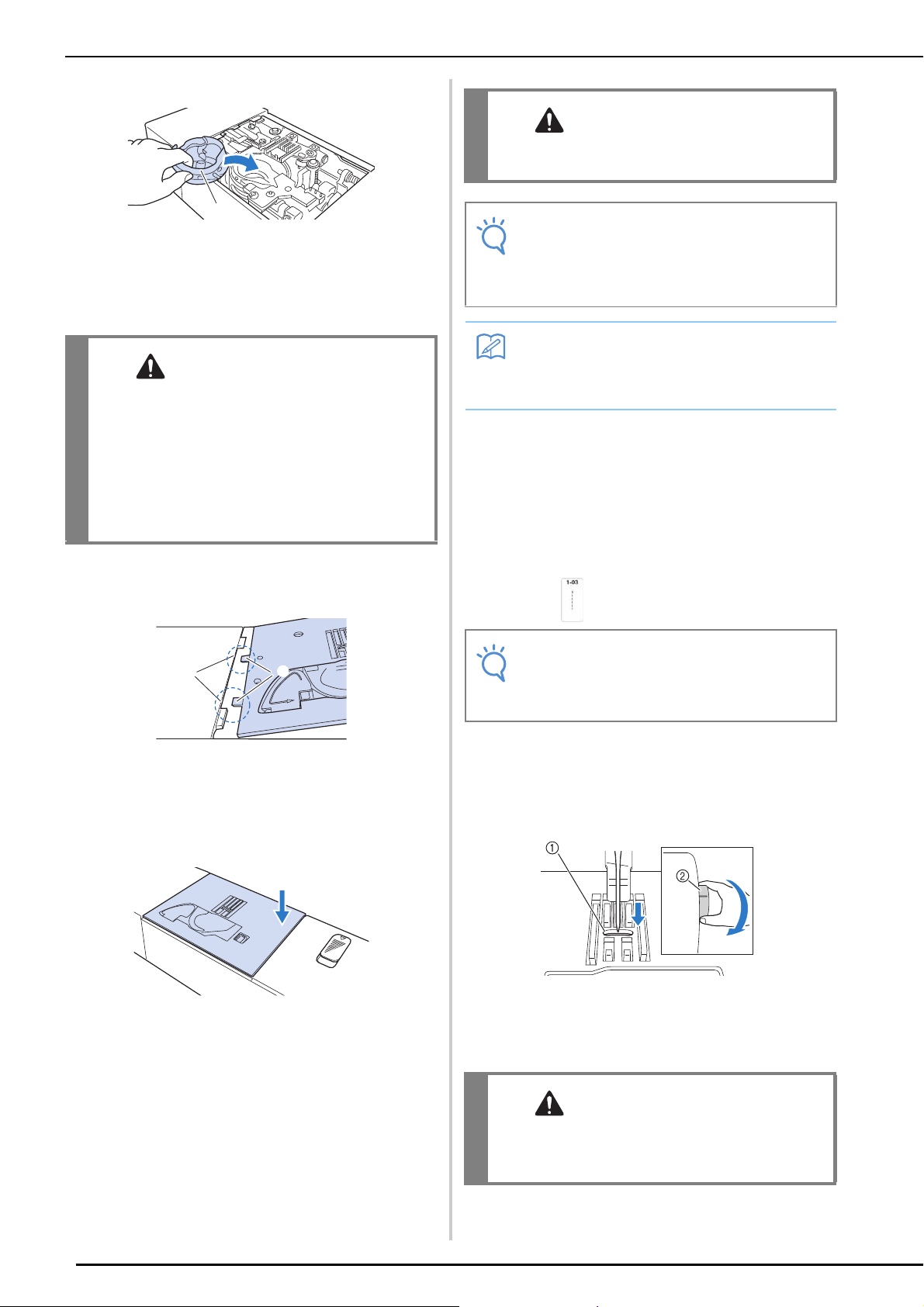

Slowly turn the handwheel toward you

(counterclockwise), and look from all sides

to check that the needle falls at the center

of the hole in the needle plate.

a Hole in the needle plate

b Handwheel

If the needle contacts the needle plate, remove the

needle plate, and then install it again.

CAUTION

• Never use a bobbin case that is scratched;

otherwise, the upper thread may become

tangled, the needle may break, or sewing

performance may suffer. For a new bobbin

case, contact your nearest Brother authorized

service center.

• Make sure that you fit the bobbin case

properly, otherwise the needle may break.

c

a

b

CAUTION

• Never use bent needles. Bent needles can

easily break, possibly resulting in injuries.

Note

• After completing this procedure, continue

with the following procedure in “Checking

Machine Operations” to check that the

machine is operating correctly.

Memo

• Since the needle may have been damaged

when the fabric was caught in the machine,

we recommend replacing it with a new one.

Note

• Do not yet install the presser foot and

thread.

• Be sure to select Straight stitch (Middle).

CAUTION

• Be sure to unplug the machine before

removing the needle plate. Otherwise, electric

shock or injury may result.

Loading ...

Loading ...

Loading ...