Loading ...

Loading ...

Loading ...

124 Adjustments for Competition

Front Suspension Adjustments

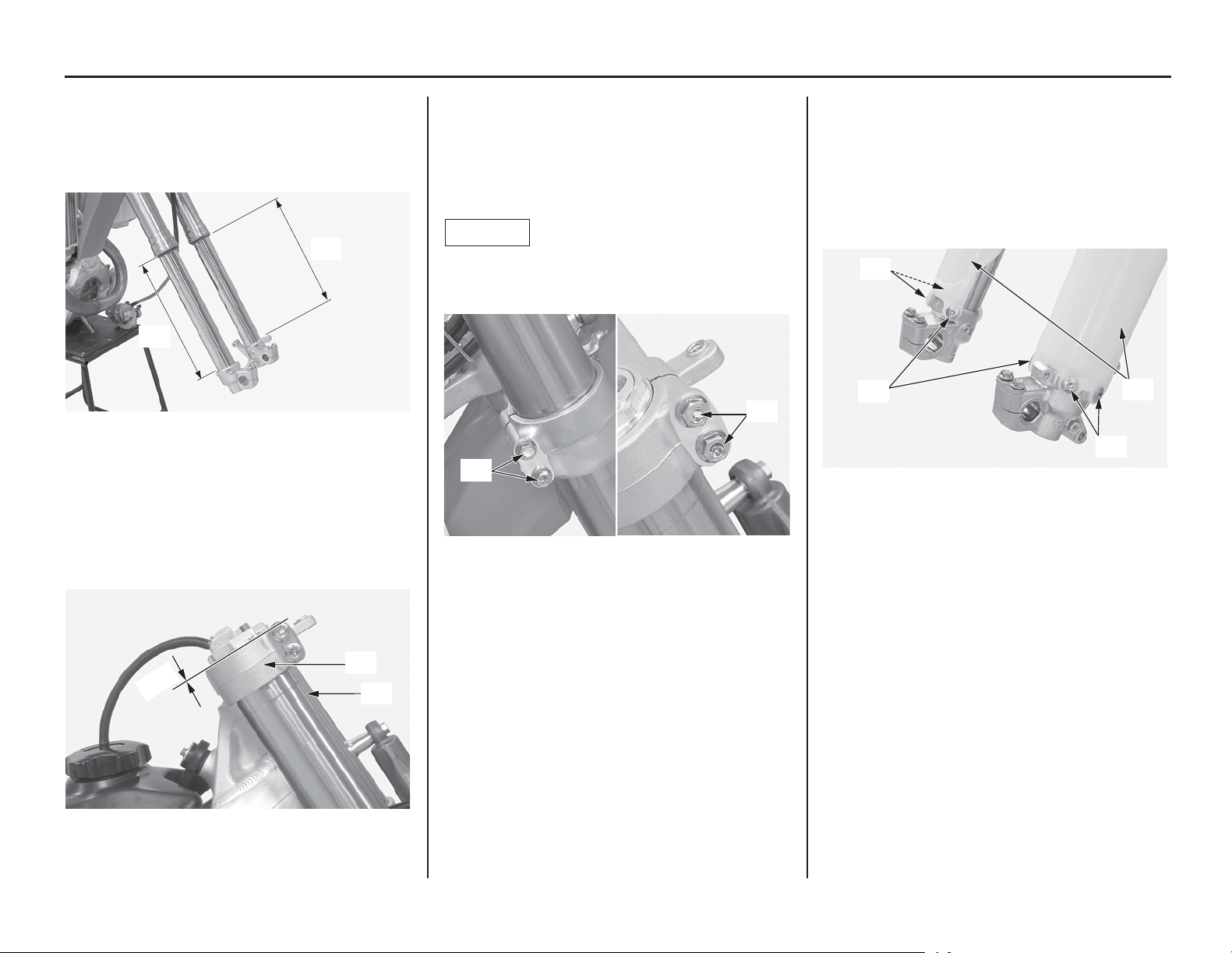

18. Compare the length (15) at assembly and at

disassembly. They should be the same length.

If the length at assembly is longer than at

disassembly, check the fork center bolt and

fork center bolt lock nut installation.

19. For ease of adjusting air pressure after the

forks are installed, loosen the fork bridge lower

pinch bolts and position the outer tubes so that

the PSF air valves are in front of the

compression damping adjusters.

Align the top of the outer tube (16) with the top

surface of the top bridge (17).

20. Tighten the fork bride lower pinch bolts (10) to

the specified torque:

15 lbf·ft (20 N·m, 2.0 kgf·m)

21. Tighten the fork bridge upper pinch bolts (18)

to the specified torque:

16 lbf·ft (22 N·m, 2.2 kgf·m)

NOTICE

Over-tightening the pinch bolts can deform the

outer tubes. Deformed outer tubes must be

replaced.

22. Clean the threads of the fork protector socket

bolts (19) and axle holder thoroughly.

Apply locking agent to the bolt threads.

Install the fork protectors (20) and fork

protector socket bolts.

Tighten the fork protector socket bolts to the

specified torque:

5.2 lbf·ft (7.0 N·m, 0.7 kgf·m)

(15) length

(16) outer tube (17) top bridge

(15)

(15)

(16)

(17)

Align

(10) fork bridge lower pinch bolts

(18) fork bridge upper pinch bolts

(18)

(10)

(19) fork protector socket bolts

(20) fork protectors

(20)

(19)

(19)

(19)

Loading ...

Loading ...

Loading ...