Loading ...

Loading ...

Loading ...

Front Suspension Adjustments

(cont’d)

Adjustments for Competition 123

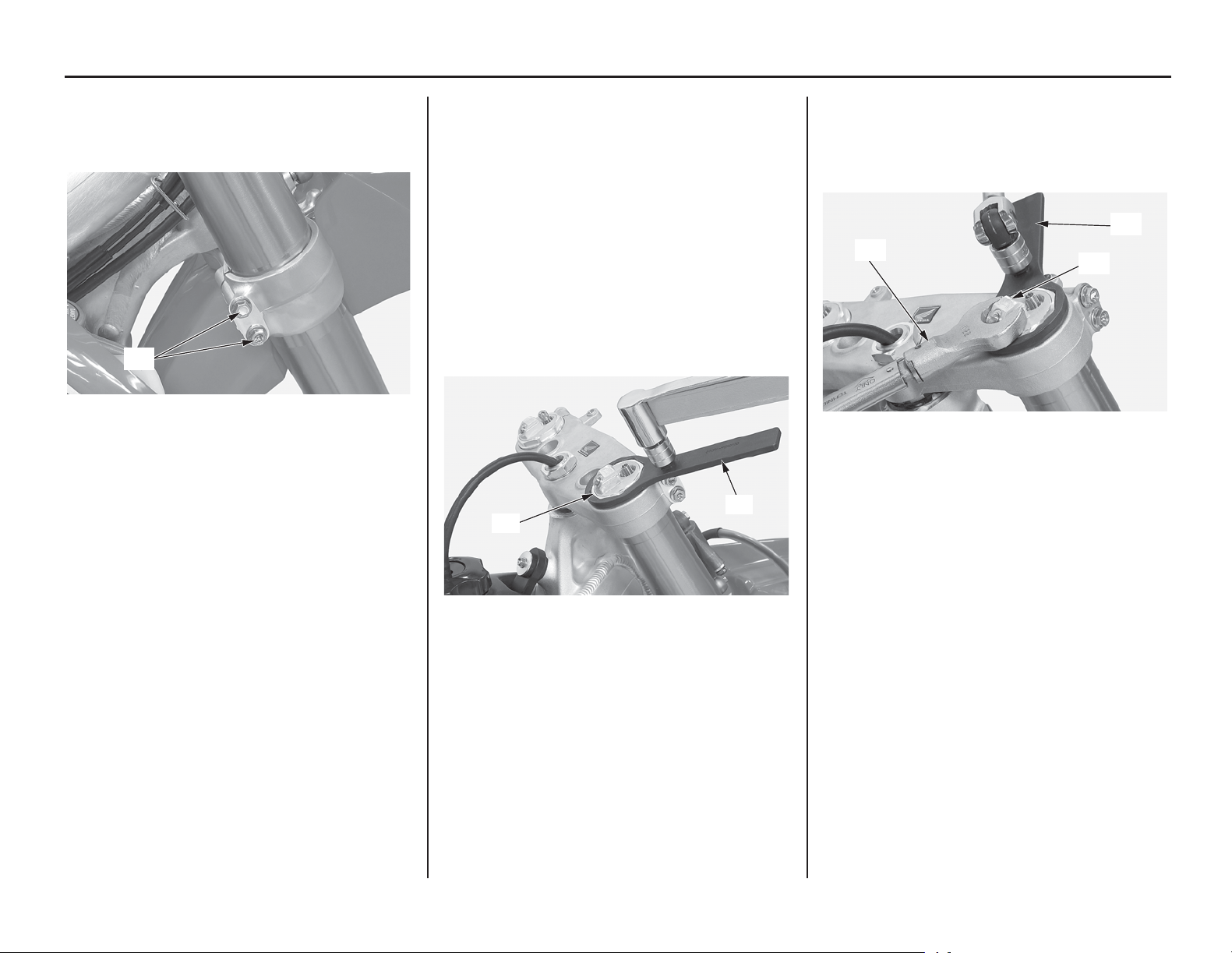

13. Insert both fork legs into the fork clamps.

Tighten the fork bridge lower pinch bolts (10)

to the specified torque:

15 lbf·ft (20 N·m, 2.0 kgf·m)

14. Tighten the fork damper (11) to the specified

torque using the lock nut wrench (12).

Actual:

22 lbf·ft (30 N·m, 3.1 kgf·m)

Torque wrench scale reading:

20 lbf·ft (27 N·m, 2.8 kgf·m), using a 20 in

(50 cm) long deflecting beam type torque

wrench.

• Lock nut wrench 070MA-MEN0100

When using the lock nut wrench, use a 20 in (50

cm) long deflecting beam type torque wrench.

The lock nut wrench increases the torque wrench’s

leverage, so the torque wrench reading will be less

than the torque actually applied to the fork damper.

15. Tighten the fork cap (13) to the specified

torque using the open end wrench (14) and the

lock nut wrench (12).

Specified torque:

21 lbf·ft (28 N·m, 2.9 kgf·m)

16. Apply air pressure of 44 psi (300 kPa, 3.1 kgf/

cm

2

) to the fork assembly and check that there

is no air leakage.

If there is no air leakage, adjust the air pressure

to specification.

Specified air pressure:

33 psi (230 kPa, 2.3 kgf/cm

2

)

17. Measure the length between the axle holder

and outer tube.

Standard:

12.44 ± 0.08 in (316.0 ± 2.0 mm)

(10) fork bridge lower pinch bolts

(10)

(11) fork damper (12) lock nut wrench

(11)

(12)

(12) lock nut wrench (14) open end wrench

(13) fork cap

(13)

(12)

(14)

Loading ...

Loading ...

Loading ...