Loading ...

Loading ...

Loading ...

120 Adjustments for Competition

Front Suspension Adjustments

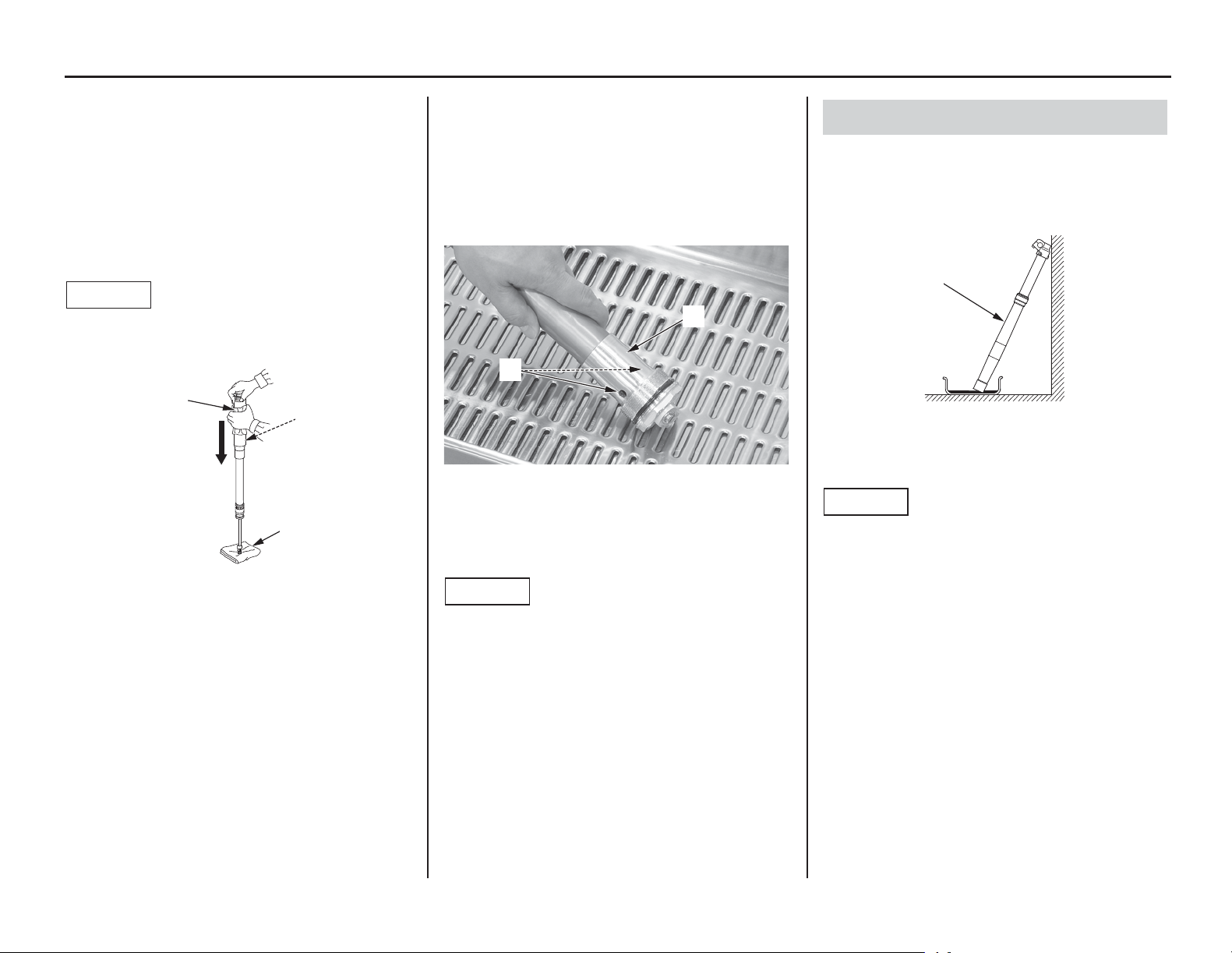

12. Check the fork damper piston rod sliding

surface for damage.

13. Cover the fork damper piston rod end with

shop towel (11) to prevent fork damage.

Cover the oil holes with shop towel (11) to

prevent blow out of fork oil.

Blow the extra oil off from the fork damper oil/

air chamber (7) by pumping the fork damper

piston rod to full stroke.

NOTICE

Be careful not to bend or damage the fork damper

piston rod when the piston rod is stroked.

14. Drain the extra oil from the oil holes (6) of the

fork damper oil/air chamber (7).

By doing above procedure, about 0.3 US oz (10

cm

3

) of fork fluid will be drained from the damper

oil/spring chamber through the oil hole and cause

11.6 US oz (343 cm

3

) of fork fluid to be left in the

chamber.

Pour the drained oil into a suitable container and

dispose of it in an approved manner (page 146).

NOTICE

Improper disposal of drained fluids is harmful to

the environment.

1. Drain the fork oil from the fork assembly (1)

by placing it upside down.

(About 0.2 US oz (7.2 cm

3

) of fork oil will be

left in the outer tube/slider when it is left

inverted for about 20 minutes at 68 °F/20 °C)

To properly dispose of drained fluids, refer to You

& the Environment on page146.

NOTICE

Improper disposal of drained fluids is harmful to

the environment.

(7) fork damper oil/air chamber

(11) shop towel

(7)

(11)

(11)

(6) oil holes

(7) fork damper oil/air chamber

(7)

(6)

Fork Assembly

(1) fork assembly

(1)

Loading ...

Loading ...

Loading ...