Loading ...

Loading ...

Loading ...

- 3

– The entire LPG unit must be continu-

ously checked to ensure that there are

no leaks and the unit is functioning

properly. Using the vehicle with a leaky

gas unit is strictly prohibited.

– First close the cylinder valve before

loosening the pipe or tube connection.

Unscrew and loosen the connection nut

of the gas cylinder slowly because oth-

erwise the gas under pressure in the

tube will flow out instantly.

– If the gas is refilled from a larger tank,

then ask the sales agent of the LPG

about the important regulations to be

followed.

Danger

Risk of injury!

– LPG in a liquid state can cause frost

bites on bare skin.

– After disconnecting the cylinder, tighten

the closing nut firmly on the connecting

threading of the cylinder.

– Use soap water or some such foaming

agent to check whether the cylinder is

leaking. The use of open flames to illu-

minate the LPG unit is strictly prohibit-

ed.

– Follow the manufacturer's installation

specifications while changing individual

parts of the LPG unit. Close all cylinder

and locking valves while doing so.

– Regularly check the status of the elec-

trical unit of the LPG vehicles. Sparks

can cause explosions if the gas-carry-

ing parts of the unit are leaky.

– If a LPG-driven vehicle has been idling

for a long time, then first ventilate the

setting room before commissioning the

vehicle or its electrical unit.

– Immediately inform the trade associa-

tion and the concerned trade superviso-

ry authority about accidents with gas

cylinders or LPG units. Store the dam-

aged parts carefully until all investiga-

tions have been completed.

– Propellants or LPG cylinders must al-

ways be stored according to the regula-

tions of TRF 1996 (Technical Regula-

tions for Liquid Gases, refer DA to BGV

D34, Appendix 4).

– Always store the gas cylinders in a ver-

tical position. Use of open flames and

smoking at the installation site of the

cylinders and during repairs is strictly

prohibited. Protect the stored cylinders

against unauthorised access. Close all

empty cylinders properly.

– Close the cylinder and main locking

valves immediately when you switch off

the vehicle.

– Follow the regulations for garages and

the construction guidelines of the re-

spective State about the location and

structure of the parking areas for LPG-

driven vehicles.

– Gas cylinders are to be stored in sepa-

rate rooms away from the parking areas

(refer DA to BGV D34, Appendix 2).

– The electrical hand-held lamps used in

the rooms are to be equipped with

closed, sealed case and a strong pro-

tection cover.

– Close all cylinder and main valves be-

fore working in repair workshops and

protect the gas cylinders against effect

of external heat.

– A responsible person must check that

all valves, especially the cylinder

valves, are closed during operational

breaks and before closing the factory.

Do not carry out any jobs involving fire -

such as cutting and welding jobs - in the

vicinity of the gas cylinders. Do not

store gas cylinders, not even empty

ones, in the workshops.

– The parking and storage rooms and the

repair workshops must be ventilated

properly. Please note that liquefied gas-

es are heavier than atmospheric air.

They get collected on the floor, in re-

cesses and other holes in the floors and

form a gas-air mixture that can lead to

explosions.

– The engine is to be brought to a stand-

still and the appliance is to be fastened

properly during transportation.

Close fuel cock.

– First switch off the appliance and re-

move the ignition key before performing

any cleaning or maintenance tasks on

the appliance, replacing parts or switch-

ing over to another function.

– Always disconnect the battery when

working on the electrics.

– Do not clean the appliance with a water

hose or high-pressure water jet (danger

of short circuits or other damage).

– Maintenance work may only be carried

out by approved customer service out-

lets or experts in this field who are famil-

iar with the respective safety regula-

tions.

– Please observe the local safety regula-

tions regarding portable commercially

used appliances.

– Always use appropriate gloves while

working on the device.

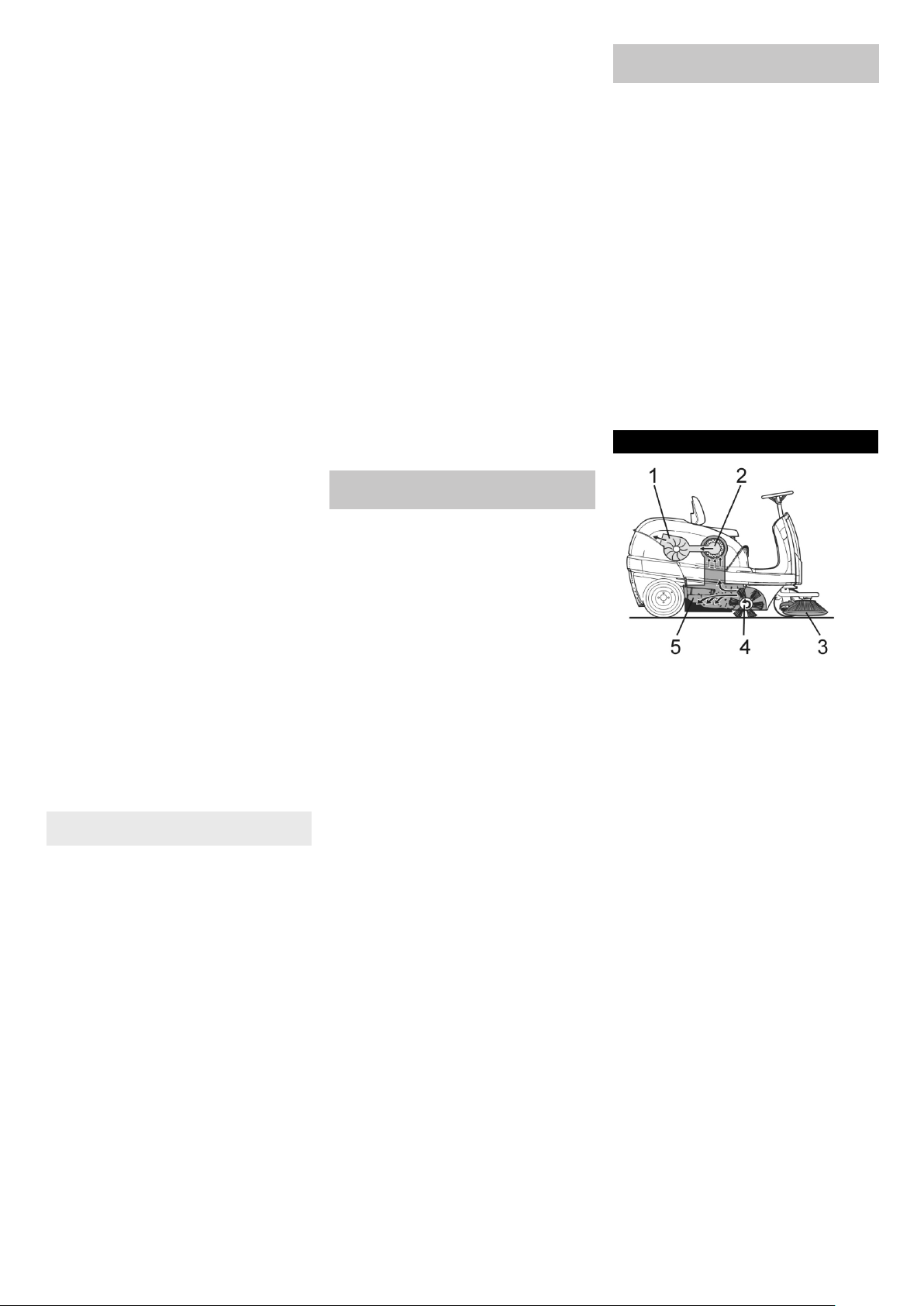

The sweeper operates using the overthrow

principle.

– The side brushes (3) clean the corners

and edges of the surface, moving dirt

and debris into the path of the roller

brush.

– The rotating roller brush (4) moves the

dirt and debris directly into the waste

container (5).

– The dust raised in the container is sep-

arated by the dust filter (2) and the fil-

tered clean air is drawn off by the suc-

tion fan (1).

In the installation and storage rooms as

well as the workshops

Safety information concerning the

transport of the appliance

Safety information concerning

maintenance and care

Function

19EN

Loading ...

Loading ...

Loading ...