Loading ...

Loading ...

Loading ...

2-10

SPEC

E

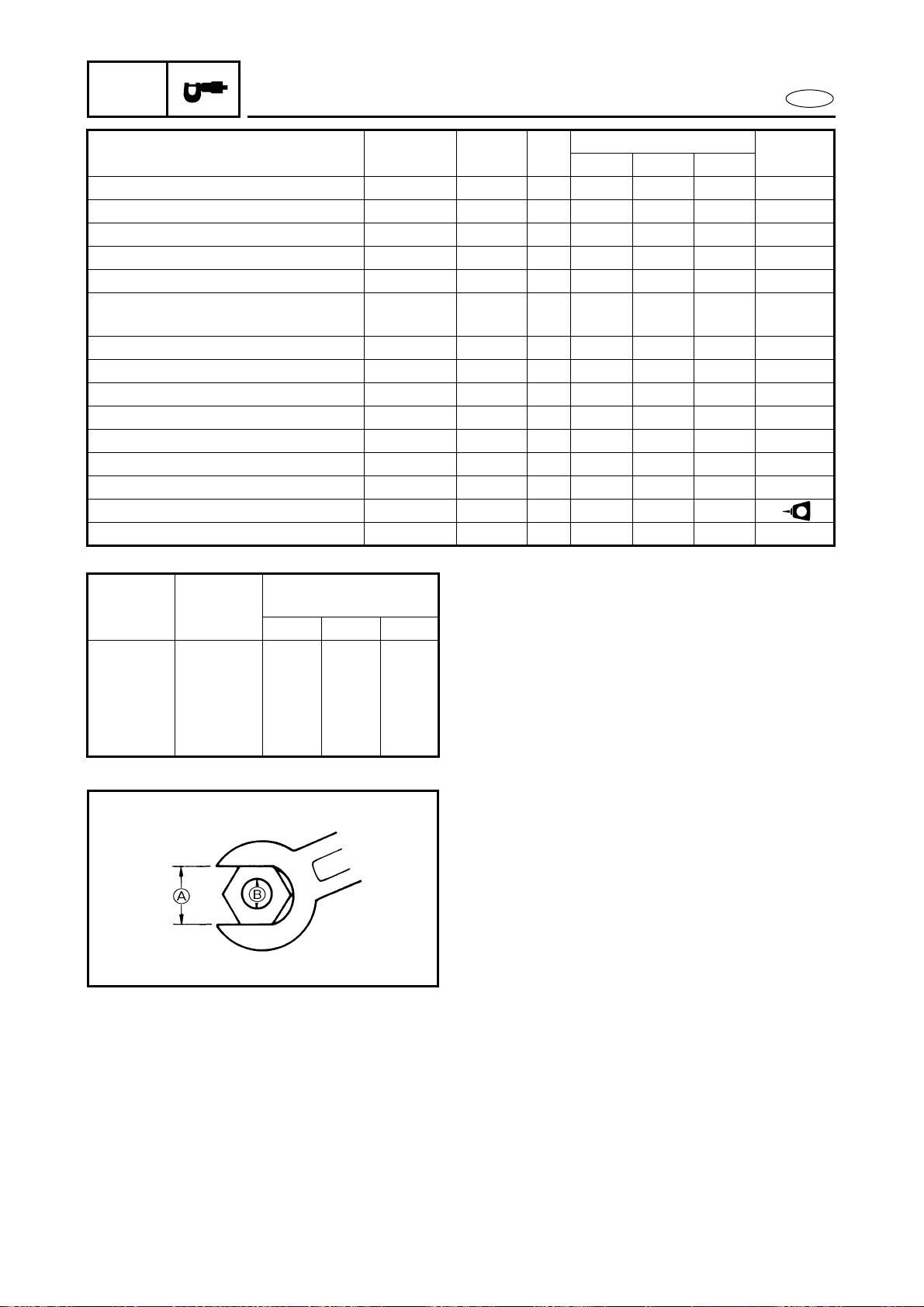

TIGHTENING TORQUES

Hand grip – deck Nut M8 2 5 0.5 3.6

Seat bracket – deck Nut M8 2 15 1.5 11

Battery box/stay – holder Nut M6 2 9 0.9 6.5

Battery box – bracket/deck Nut M8 2 13 1.3 9.4

Battery box – electrical box Bolt M8 3 15 1.5 11

Extension bolt – battery negative

terminal

Bolt M6 1 6 0.6 4.3

Exhaust outlet – hull Bolt M6 3 6 0.6 4.3

Sponson – hull Bolt M8 6 18 1.8 13

Spout – hull Nut M24 1 5 0.5 3.6

Rope hole – hull Nut M24 2 5 0.5 3.6

Bow eye – hull Bolt M6 2 13 1.3 9.4

Flap – hull Bolt M6 8 6 0.6 4.3

Drain plug/packing – hull Nut M5 4 2 0.2 1.4

Engine mount – hull Bolt M8 8 17 1.7 12

572

LT

Engine damper – hull Bolt M6 2 6 0.6 4.3

Part to tightened Part name

Thread

size

Q’ty

Tightening torque

Remarks

N•m kgf•m ft•lb

GENERAL TORQUE

This chart specifies tightening torques for

standard fasteners with a standard ISO

thread pitch. Tightening torque specifica-

tions for special components or assemblies

are provided in applicable sections of this

manual. To avoid warpage, tighten multi-

fastener assemblies in a crisscross fashion

and progressive stages until the specified

tightening torque is reached. Unless other-

wise specified, tightening torque specifica-

tions require clean, dry threads.

Components should be at room tempera-

ture.

Nut A Bolt B

General torque

specifications

N•m kgf•m ft•lb

8 mm M5 5.0 0.5 3.6

10 mm M6 8.0 0.8 5.8

12 mm M8 18 1.8 13

14 mm M10 36 3.6 25

17 mm M12 43 4.3 31

Loading ...

Loading ...

Loading ...