Loading ...

Loading ...

Loading ...

SERVICE

&

MAINTENANCE INSTRUCTIONS

HYDRAULIC VALVE REPAIR

(Figure

34)

Valve repair should be accomplished in a clean

work place. Individual components for many

of

the

assemblies are not available as repair parts. This

will simplify repair and allow you to replace

complete assemblies.

~

Pressure Settings on

ShocWDampenmg Valves

Pressure settings on shocWdampening valves are

preset at the factory. Although they are adjustable,

they must not be reset in the field using backhoe

hydraulic system. The backhoe pump will separate

or

crack

if

system pressure exceeds the maximum.

Relief valve adjustment requires

a

test bench and

accurate gauges.

Adjusting System Relief Valve

Pressure

Place a pressure gauge in the pump pressure line

at the relief valve. When installing pressure gauge,

be sure to use steel fittings that will withstand

working pressure up to

5000

psi. Remove cap nut

(6a). Adjusting screw (6c) has a hex socket

-

rotate

screw clockwise to increase pressure and

counter

-

clockwise to decrease pressure. Start

tractor PTO and set system relief valve pressure at

2000

psi. When pressure

is

adjusted, shut tractor

PTO

and

tractor

off.

Replace cap nut (6a) on

system valve.

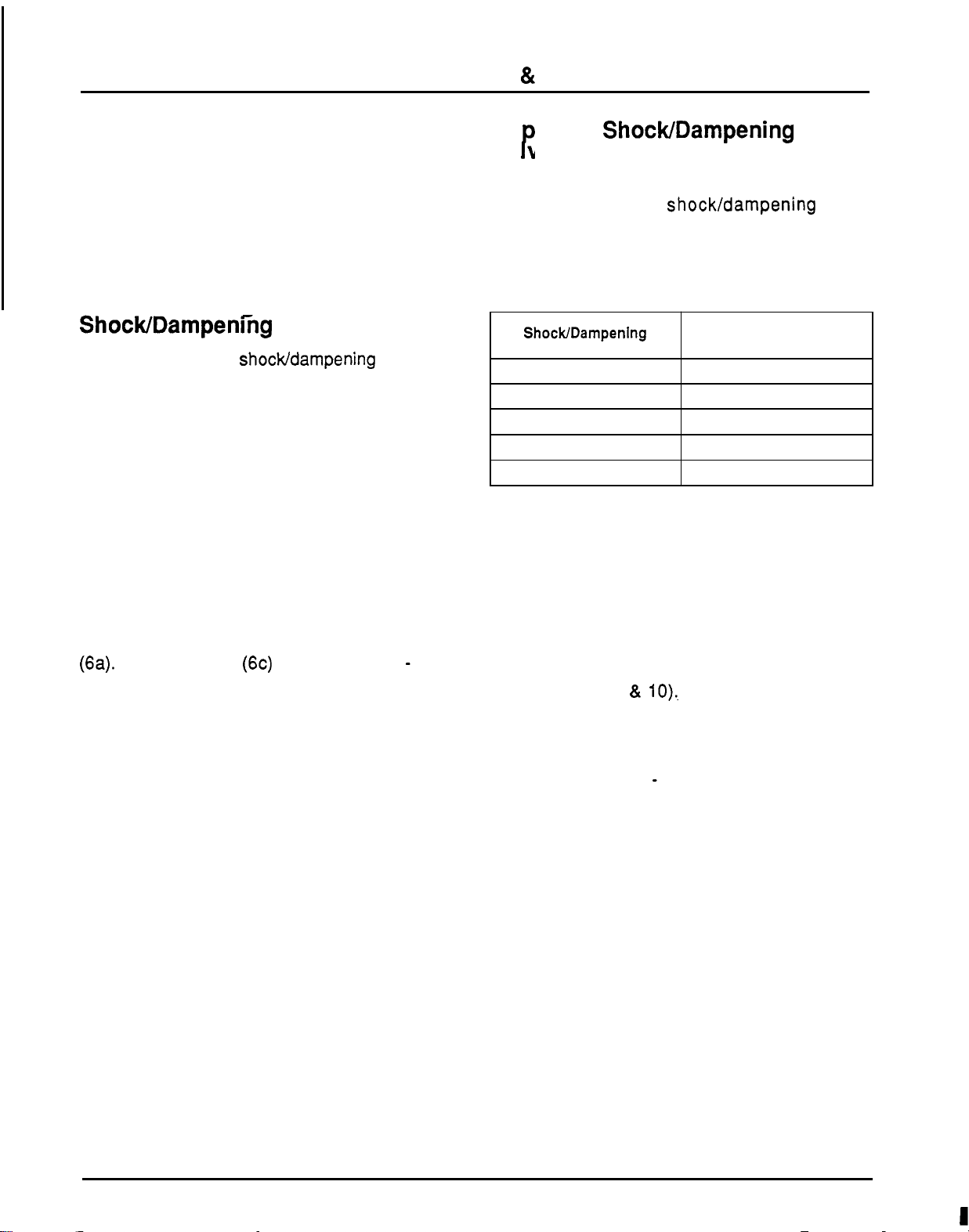

Re lacing ShocWDarnpening

Va

P

ves

It is not necessary

to

remove console valve from

console to replace

shock/dampening valve

cartridges. Remove console cover and replace

them. Be sure you install valve cartridges set at the

correct pressure. Valves are similar and can be

easily mixed up.

.

ShocWDampening

Pressure

2

3500

PSI

.

4AA

4BB

2000

PSI

2500

PSI

5

2000

PSI

4cc

2500

PSI

Valve

Setting

Segment Replacement

1.

2.

3.

Relieve system pressure and remove valve

from backhoe. Remove tie rods and separate

the valve sections.

Replace defective sections as necessary.

Make sure you install

two

spacers between

each section of each tie rod. Note the location

of O

-

rings

(9

&

lo)..

They must be placed in

location between valve sections as shown.

When assembling valve sections, use care

when torquing nuts on tie rods. This must be

done in steps

-

that is to say, gradually

increasing the tightening torque up to

13

ft

-

lbs.

in an alternating sequence. Non

-

uniform

or

excessive tightening can cause binding of

spools. Failure to attain the proper torque can

result

in

leaks. Always use

a

torque wrench.

40

Loading ...

Loading ...

Loading ...